Sound absorption material and preparation method thereof

A sound-absorbing material, mass percentage technology, applied in the field of sound-absorbing materials, can solve problems such as limited application range, low penetration rate of micropores, general sound-absorbing effect, etc., and achieve improved sound-absorbing performance, large pore size range, and good thermal performance and the effect on the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

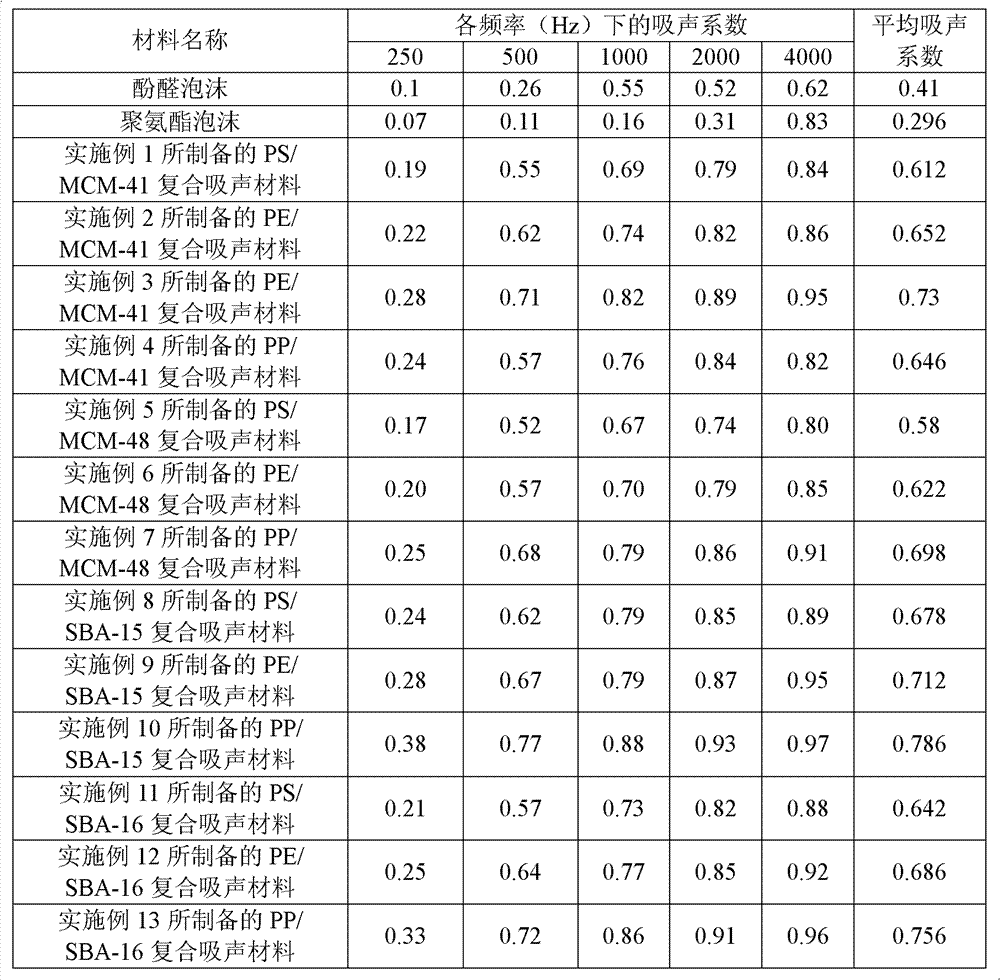

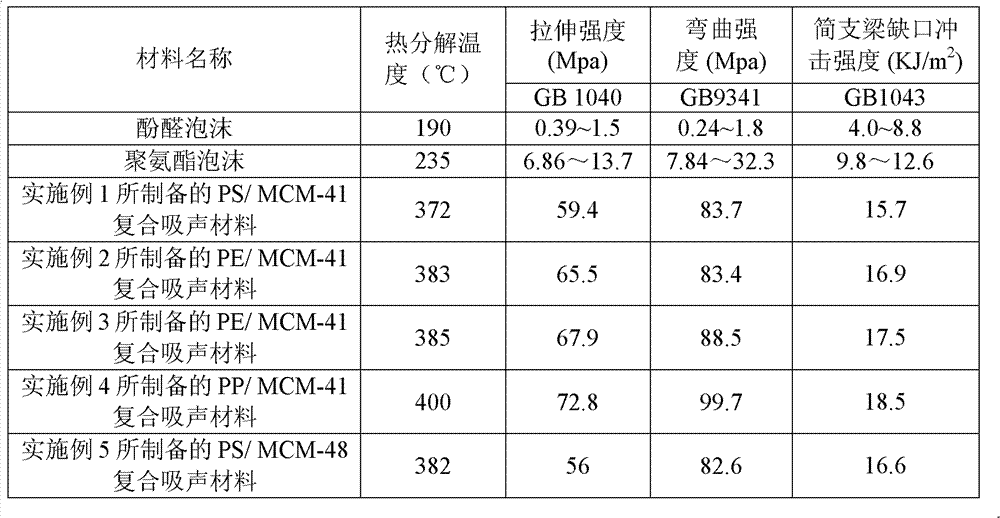

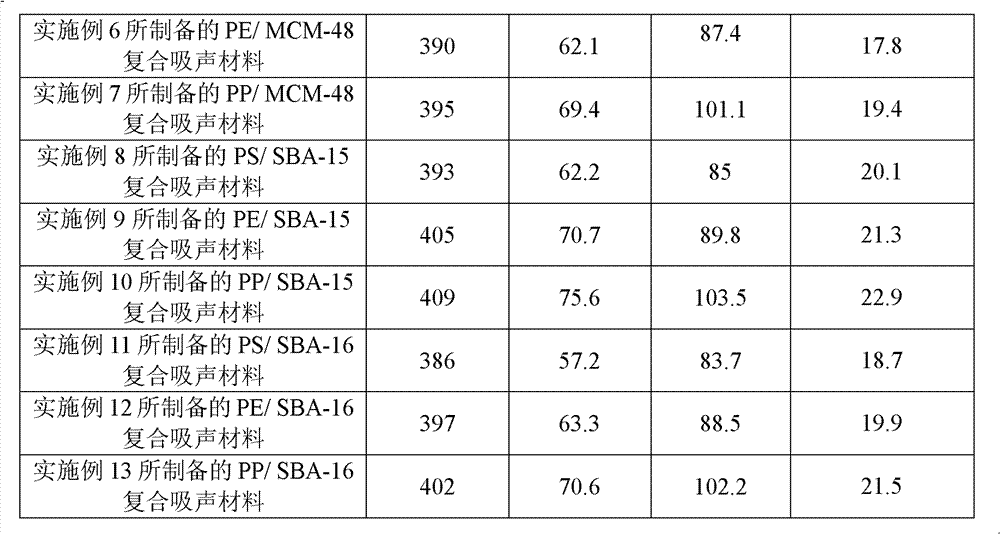

Examples

Embodiment 1

[0025] Embodiment 1: first by mass percent 40% polystyrene (PS) and 34% ethylene propylene rubber (EPR), 20% mesoporous molecular sieve MCM-41, 3% anhydrous zinc borate and 3% CZX-768 without Stir and mix the poisonous calcium-zinc composite stabilizer evenly; knead the above mixture on a kneader at 130°C for 10 minutes to prepare PS / MCM-41 composite sound-absorbing material.

[0026] Polystyrene (PS) grade is Taiwan Chemical Fiber PS 5250, provided by Chengdu Golden Eagle Group Trading Co., Ltd.; ethylene propylene rubber (EPR) grade J-0030, provided by Jilin Xingyun Chemical Co., Ltd. of Jihua Group; MCM-41 mesoporous molecular sieve : The product produced by Nanjing Xianfeng Nano Material Technology Co., Ltd. is a mesoporous molecular sieve with a hexagonal ordered pore structure and long-range order. Its pore size is 3.5nm and its BET specific surface area is ≥900m 2 / g, pore volume ≥ 0.6cm 3 / g. Anhydrous zinc borate was provided by Chengdu Kaifei High Energy Chemical I...

Embodiment 2

[0027] Embodiment 2: first by mass percent 30% polyethylene (PE) and 18% butyl rubber, 50% mesoporous molecular sieve MCM-41, 1% magnesium hydroxide flame retardant and 1% mercaptan organotin (8831 ) heat stabilizer and stir and mix evenly; the above mixture is kneaded for 20 minutes at a temperature of 110° C. on a kneader to prepare a PE / MCM-41 composite sound-absorbing material.

[0028] Polyethylene (PE) is Jilin Petrochemical general film material 7042, melt index 1.7-2.3g / 10min density: 0.918~0.922g / cm 3 ; Butyl rubber model: Japan JSR 268, provided by Chengdu (Hengyu) Chemical Trading Co., Ltd.; magnesium hydroxide flame retardant provided by Shandong Luhua Chemical Co., Ltd.; mercaptan organotin (8831) heat stabilizer provided by Beijing Provided by San'an Chemical Products Co., Ltd.

Embodiment 3

[0029] Embodiment 3: first by mass percentage 20% polyethylene (PE) and 13% butyl rubber, 65% mesoporous molecular sieve MCM-41, 1% magnesium hydroxide and 1% mercaptan organotin (8831) thermal stability The agent is stirred and mixed evenly; the above mixture is kneaded for 20 minutes at a temperature of 110°C on a kneader to prepare a PE / MCM-41 composite sound-absorbing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com