Photoluminescence material with frequency synergistic light conversion and preparation method as well as use thereof

A photoluminescent material and photoluminescent technology, applied in luminescent materials, photovoltaic power generation, chemical instruments and methods, etc., can solve problems that restrict photovoltaic efficiency, eliminate heat loss and sub-band loss, simple composition, easy synthesis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

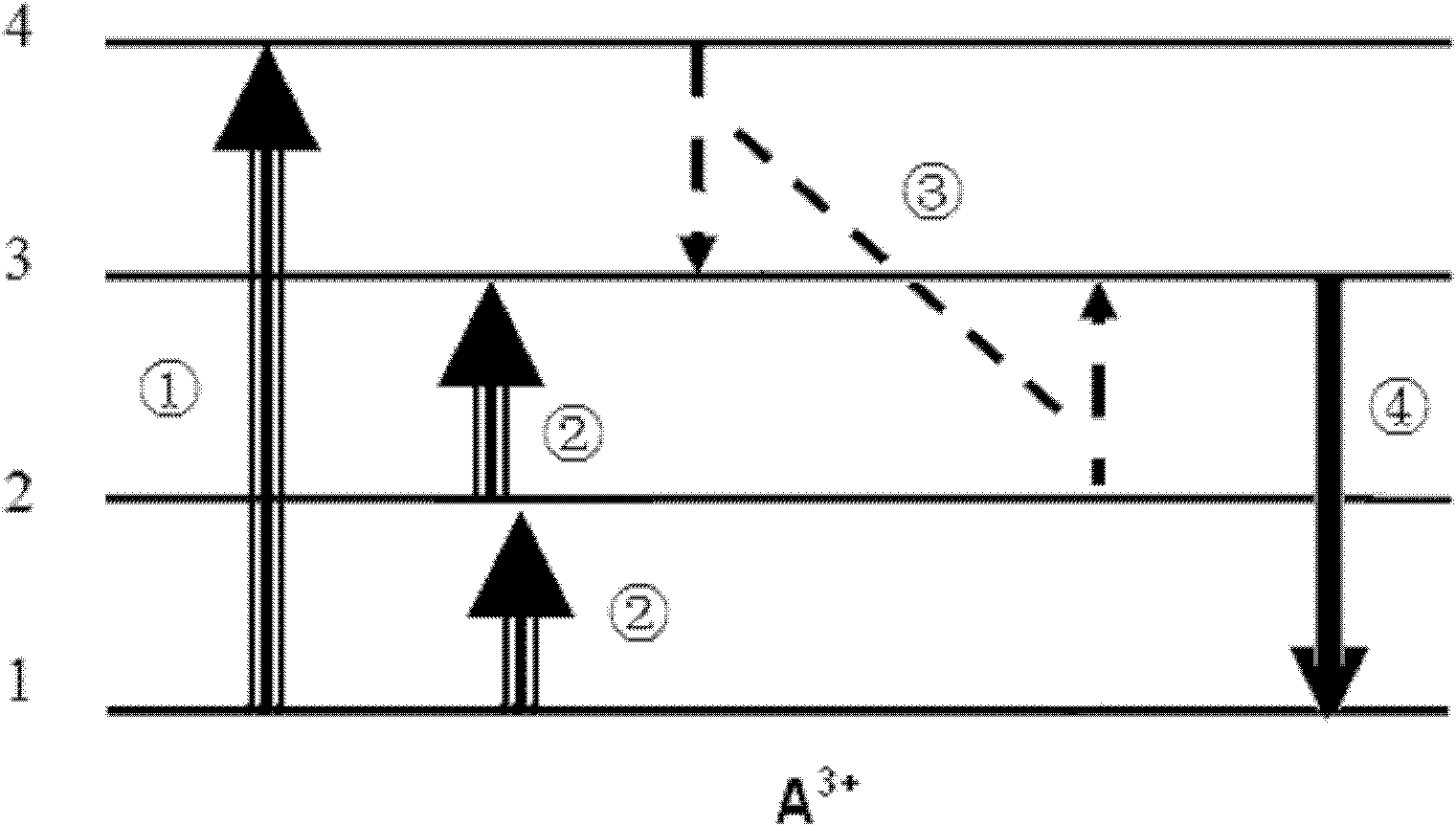

Method used

Image

Examples

Embodiment 1

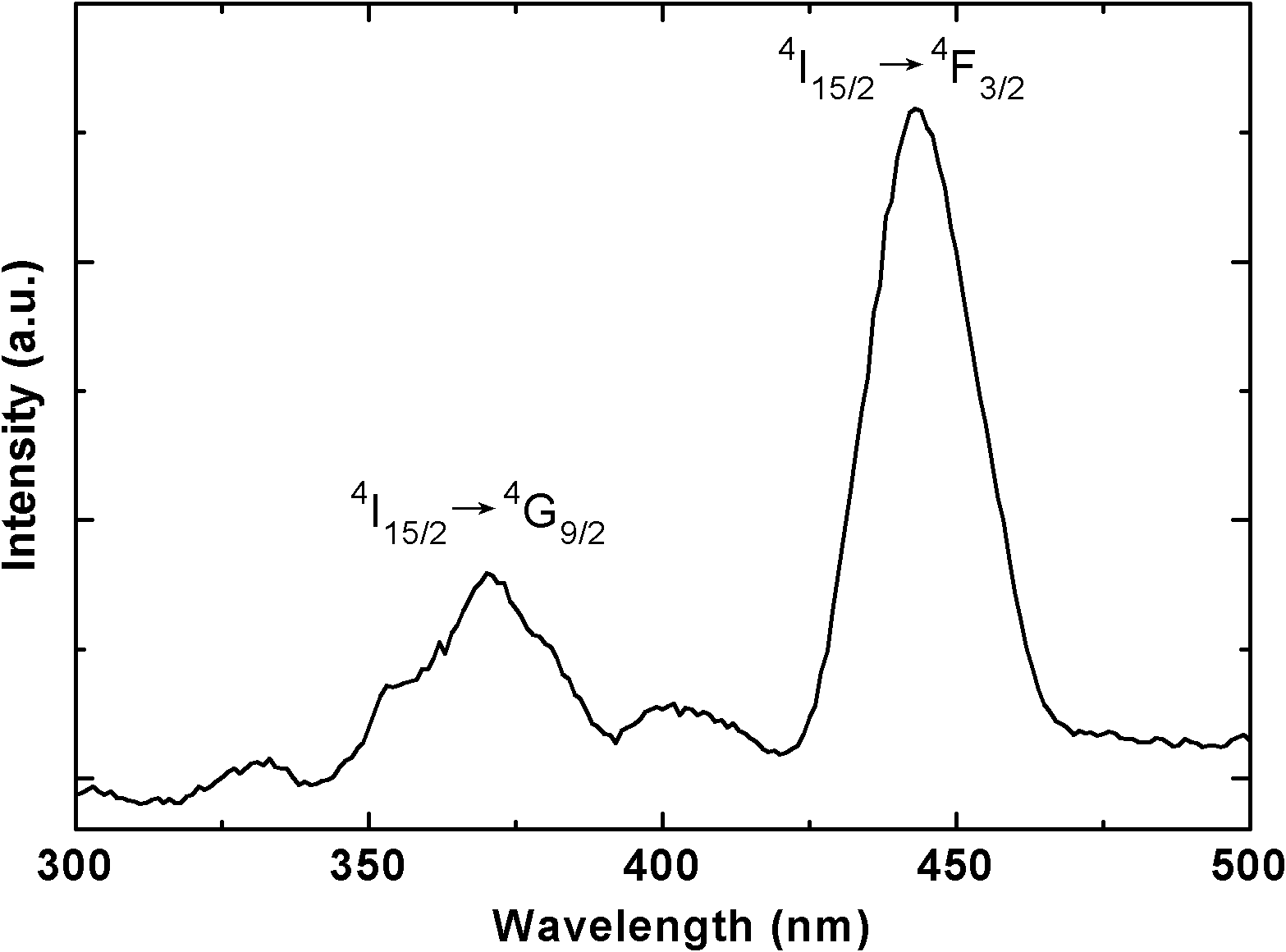

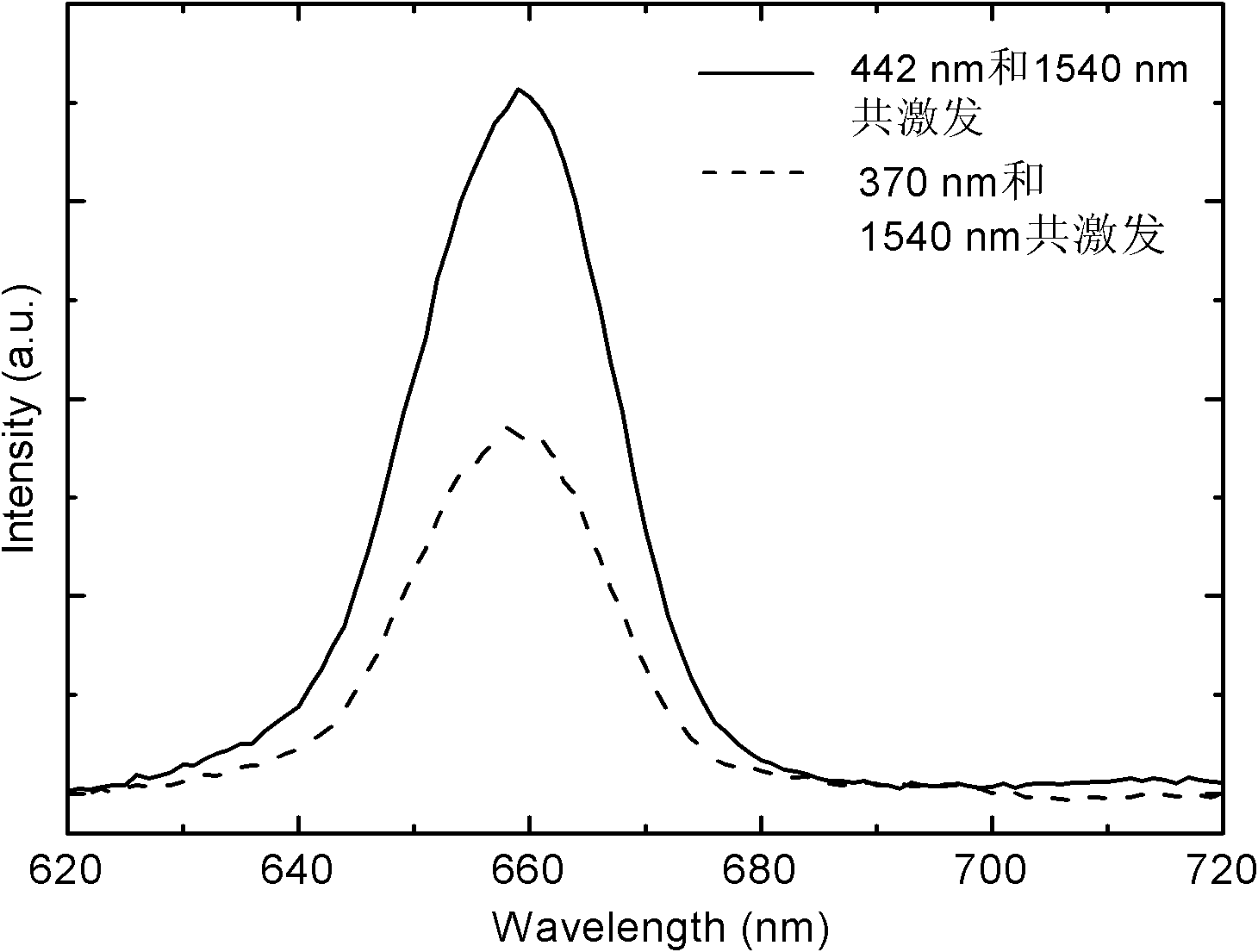

[0041] Synthesis of stoichiometric equation as NaGd by high temperature solid phase method 0.80 Er 0.20 f 4 s material. Weigh 0.3252g NaF, 0.3474g ErF 3 and 1.3274 g GdF 3 Rare earth fluorides were used as raw materials, mixed evenly and ground for half an hour, and then added 2 mL of absolute ethanol to continue grinding for one hour. Put the mixture into a corundum crucible and then transfer it to a tube furnace. Take another crucible and put 0.60 g of NH 4 HF 2 , both ends of the tube furnace are closed. Calcined at 700°C for 6 hours and cooled naturally to obtain the sample. For the excitation spectrum of the prepared sample emission peak at 659nm, see figure 2 . For the luminescence spectrum of the prepared sample under the common excitation of 442nm and 1540nm, or the common excitation of 370nm and 1540nm, see image 3 .

Embodiment 2

[0043] Synthesis of stoichiometric equation as NaGd by high temperature solid phase method 0.50 Er 0.50 f 4 s material. Weigh 0.3215g NaF, 0.8584g ErF 3 and 0.8201 g GdF 3 Rare earth fluorides were used as raw materials, mixed evenly and ground for half an hour, and then added 2 mL of absolute ethanol to continue grinding for one hour. Put the mixture into a corundum crucible and then transfer it to a tube furnace. Take another crucible and put 0.60 g of NH 4 HF 2 , both ends of the tube furnace are closed. Calcined at 700°C for 6 hours and cooled naturally to obtain the sample.

Embodiment 3

[0045] Synthesis of stoichiometric equation as NaGd by high temperature solid state method 0.50 Er 0.50 f 4 s material. Weigh 0.3215g NaF, 0.8584g ErF 3 and 0.8201 g GdF 3 Rare earth fluorides were used as raw materials, mixed evenly and ground for half an hour, and then added 2 mL of absolute ethanol to continue grinding for one hour. Put the mixture into a corundum crucible and then transfer it to a tube furnace. Take another crucible and put 0.60 g of NH 4 HF 2 , both ends of the tube furnace are closed. Calcined at 1000°C for 4 hours and cooled naturally to obtain the sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com