Cooling and heat-conducting composite material, preparation method thereof, cooling mat rubber core manufactured by using composite material and cooling mat including cooling mat rubber core

A heat-conducting composite material and cold storage technology, which is applied in the field of cooling pad rubber core and cooling pad, can solve the problems of weakness of the whole body, sore muscles and joints, etc., and achieve the effect of simple preparation process, low cost of tooling and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

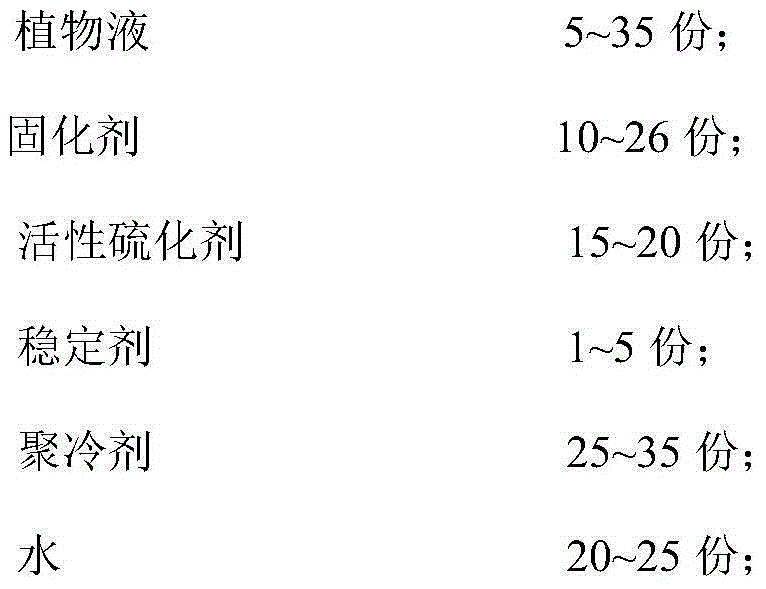

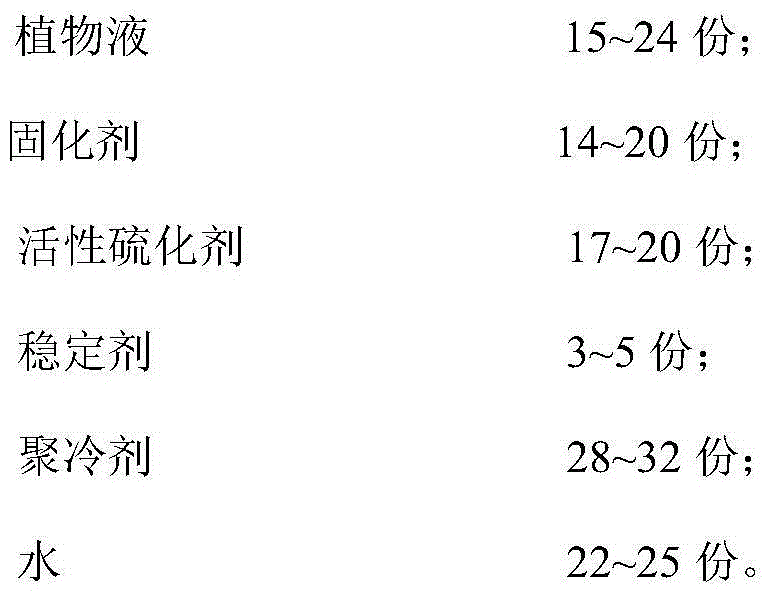

[0016] According to a typical embodiment of the present invention, the present invention provides a cold-storage and heat-conducting composite material. The cold-storage and heat-conducting composite material includes the following components in parts by weight: 5-35 parts of plant liquid; 10-26 parts of curing agent; 15-20 parts of active vulcanizing agent; 1-5 parts of stabilizer; 25-35 parts of polyrefrigerant; The agent is sucrose and / or xylitol, the polycooling agent is urea and / or mint, and the active vulcanizing agent is one or more of tartaric acid, lactic acid and salicylic acid.

[0017] By using cool plant aloe vera liquid and / or cactus liquid as raw materials, and adding stabilizer, active vulcanizing agent, cooling agent and curing agent, the cold storage and heat conduction composite material is obtained after mixing, and the cold storage and heat conduction composite material is solidified and formed to obtain The cooling pad with a thermal conductivity of 0.6-1...

Embodiment 1

[0027] Take 30 parts of pure squeezed aloe liquid obtained after squeezing the liquid of aloe vera, add it to 24 parts of water, stir evenly, and obtain the diluted plant liquid. Add 18 parts of active vulcanizing agent salicylic acid, 5 parts of stabilizer xylitol and 3 parts of polycooling agent mint into the plant liquid while stirring at room temperature, and stir for 5 minutes to obtain a plant mixed liquid.

[0028] Add 20 parts of curing agent polyacrylamide (molecular weight is 1.6×10 7 ), and stirred for 30 minutes to obtain a viscous composite material. Put the viscous composite material into a closed container, vacuumize it for 5 minutes, then put it into a molding mold, let it stand and solidify for 15 days, and obtain the rubber core of the cooling pad. The ASTM-D5470 method of the international general standard American Society for Testing and Materials (ASTM) is used to test the thermal conductivity of the rubber core of the cooling pad, and the tension and pre...

Embodiment 2

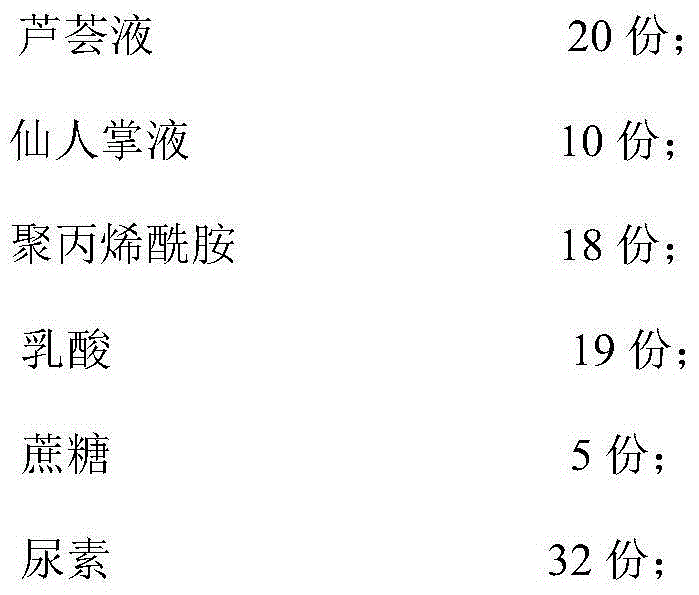

[0030] Take 20 parts of pure aloe liquid and 10 parts of cactus liquid obtained after squeezing the liquid of Aloe vera, mix them with 22 parts of water and stir evenly to obtain the diluted plant liquid. Add 19 parts of active vulcanizing agent lactic acid, 5 parts of stabilizer sucrose and 32 parts of polyrefrigerant urea into the plant solution at 20°C, and stir for 5 minutes to obtain a plant mixture.

[0031] Add 18 parts of curing agent polyacrylamide (molecular weight is 0.5×10 7 ), and stirred for 15 minutes to obtain a viscous mixture. Put the viscous composite material into a closed container, vacuumize it for 5 minutes, then put it into a molding mold, let it stand and solidify for 15 days, and obtain the rubber core of the cooling pad. The ASTM-D5470 method of the international general standard American Society for Testing and Materials (ASTM) is used to test the thermal conductivity of the rubber core of the cool pad, and the elastic coefficient of the rubber cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com