Method for lowering ultrahard multi-layer thin film residual stress based on high-intensity pulsed ion beam technique

A high-current pulse, multi-layer film technology, applied in ion implantation plating, coating, metal material coating process, etc. Thin film applications and other issues, to achieve good energy deposition depth distribution, process reliability and repeatability, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

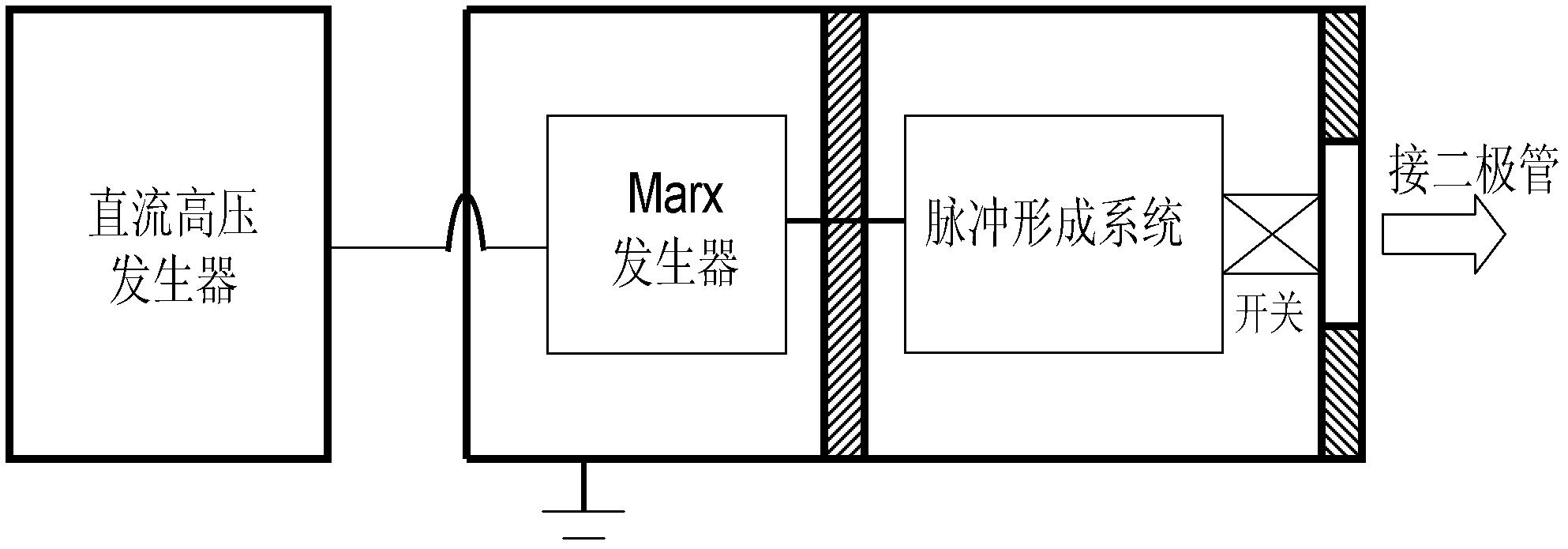

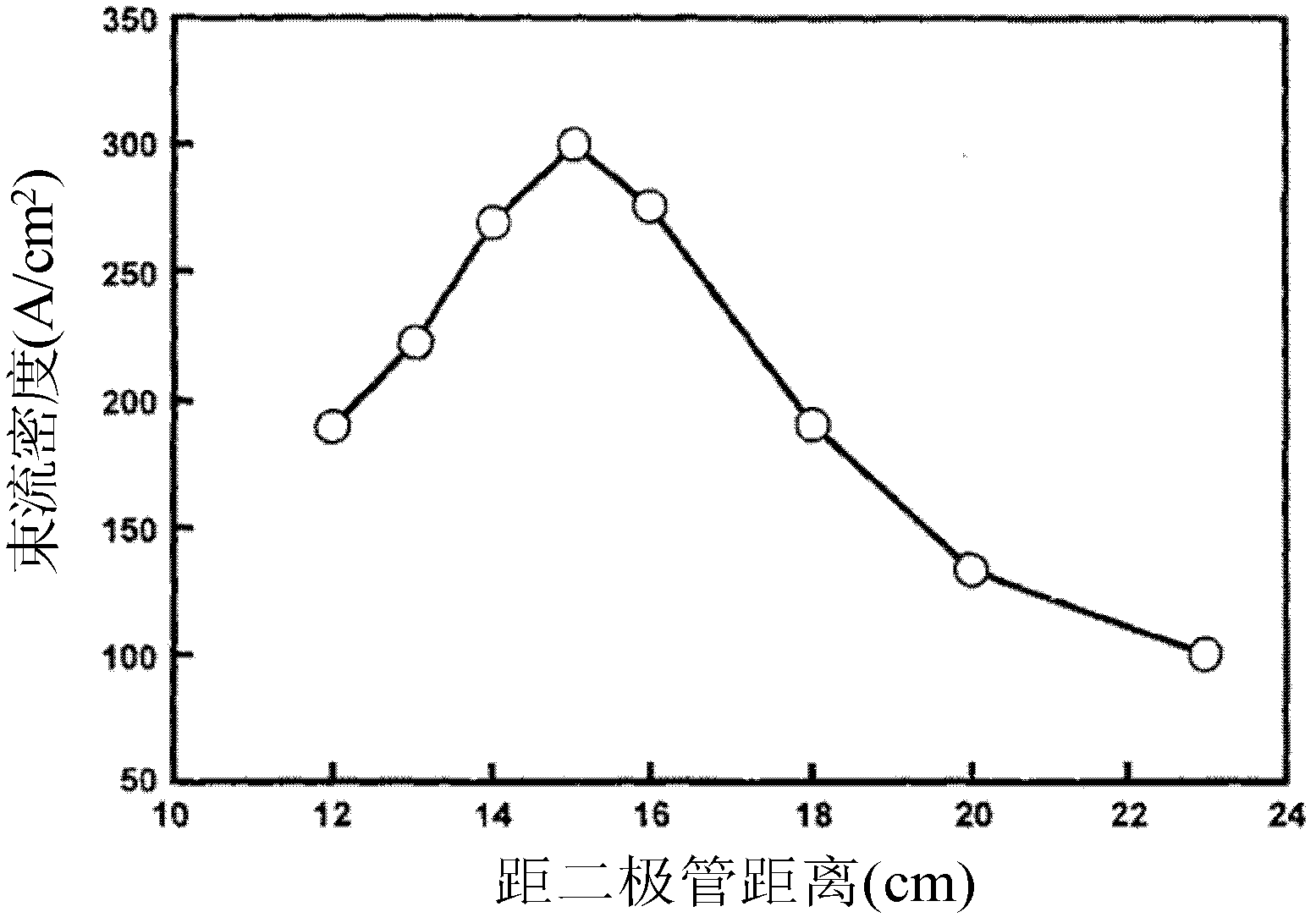

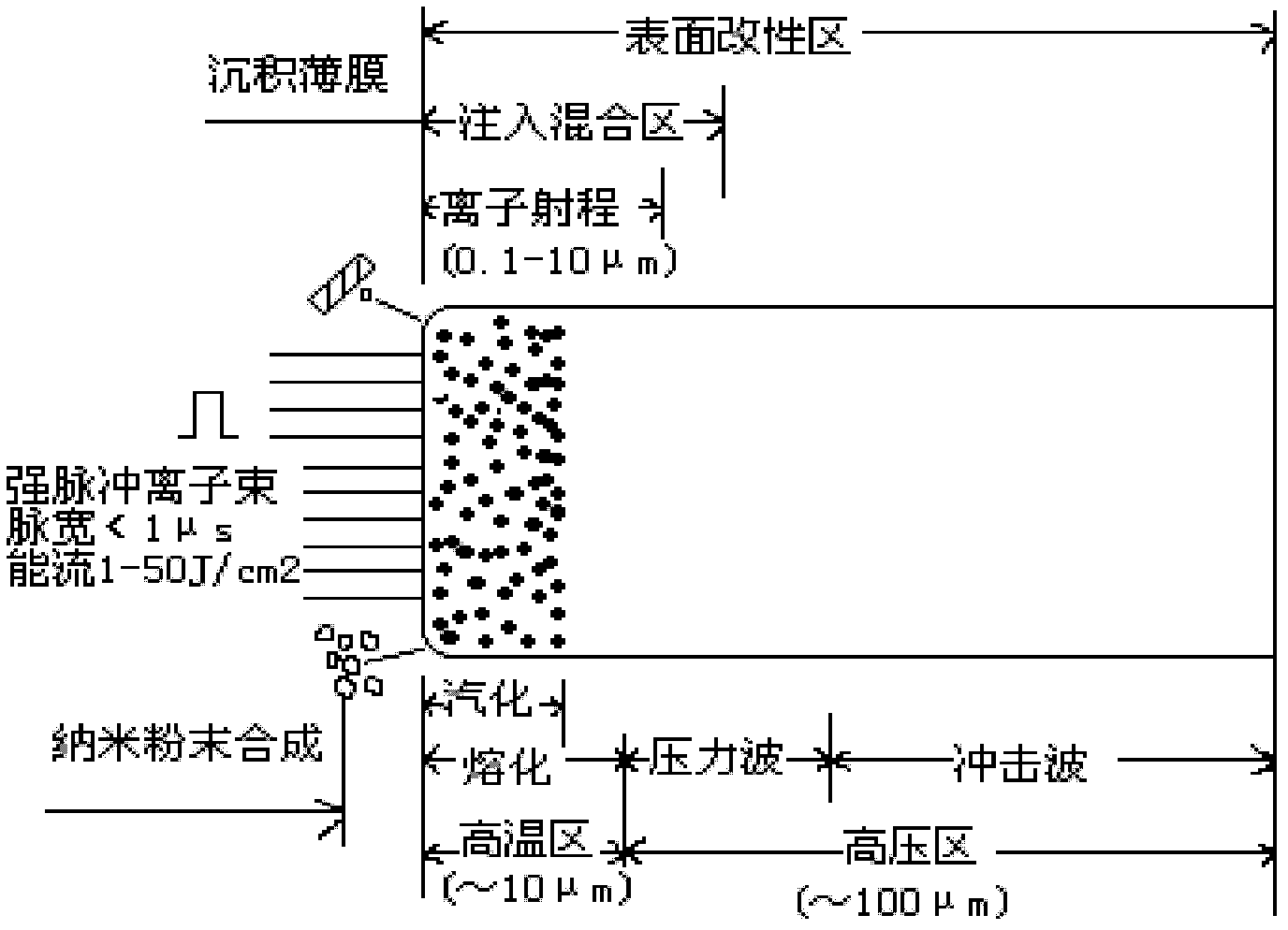

[0043] use figure 1 The TEMP-6 high-current pulsed ion beam device is shown, the TEMP-6 device uses a polymer anode unipolar pulse mode external magnetically insulated ion diode, and the beam density distribution is as follows figure 2 shown. Ion beam composition is 30% C n+ and 70%H + , the acceleration voltage is 300 ~ 350kV, the pulse width is 70ns, and the beam current density is adjusted according to the specific composition of the film. Superhard multilayer films with different compositions and different modulation periods were prepared by arc ion plating technology, and the phase structure of the films was measured by X-ray diffraction technology. Put the film into the irradiation chamber of the HIPIB device and evacuate to 10 -3 Pa, respectively choose different beam densities and different irradiation times to irradiate the film, the surface morphology, phase structure and grain size of the film after irradiation all change (such as Figure 4 and Figure 5 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com