Method for preparing methylamine by using methanol gas ammonification method

A technology for preparing methylamine and methanol, which is applied to the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, and can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

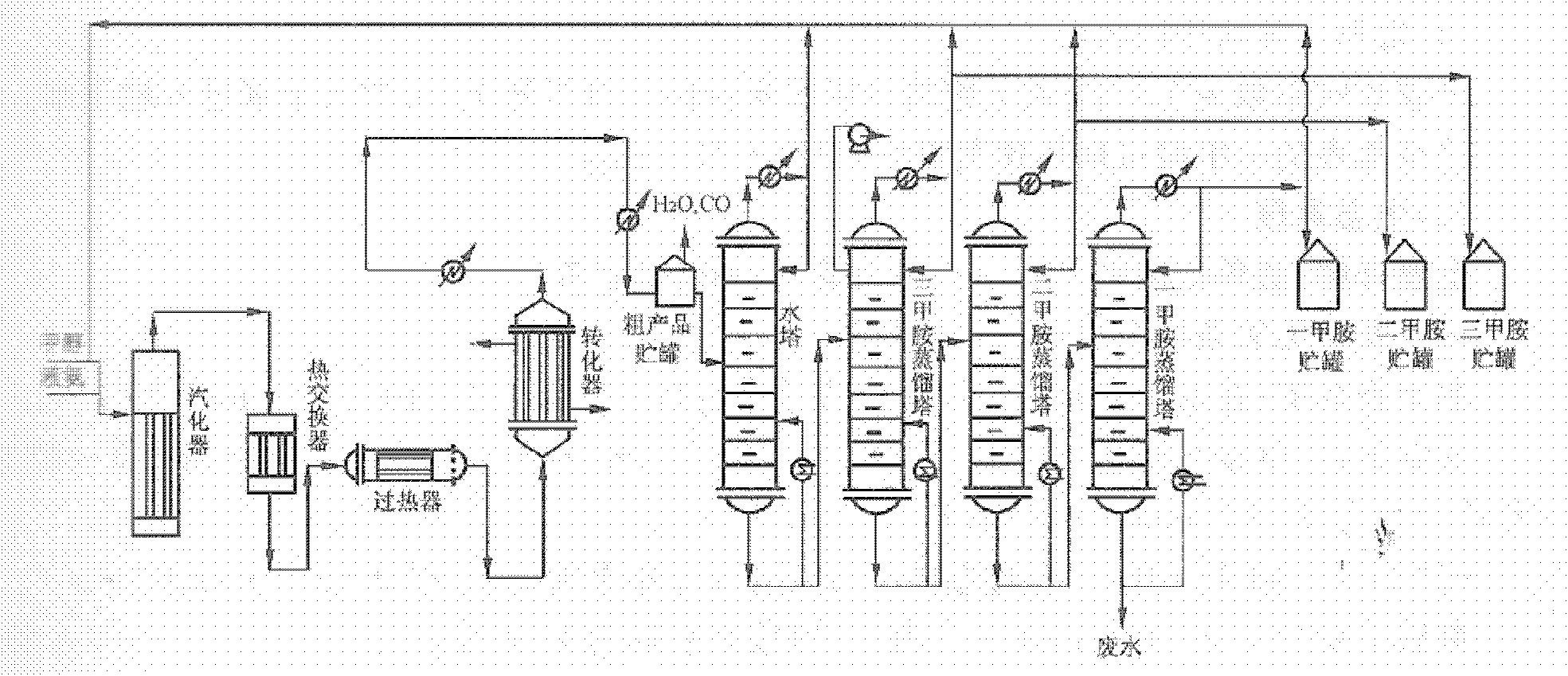

[0019] Mix methanol:ammonia=1:4 in parts by weight, use a mixture of activated alumina and silicon oxide as a catalyst, the reaction temperature is 250°C, the reaction pressure is 0.5MPa, and the space velocity is 1500h-1. see details figure 1 .

Embodiment 2

[0021] Mix methanol:ammonia=1:4 in parts by weight, use a mixture of activated alumina and titanium dioxide as a catalyst, the reaction temperature is 500°C, the reaction pressure is 5.0MPa, and the space velocity is 500h-1, see figure 1 .

Embodiment 3

[0023] Methanol: ammonia=1: 4 parts by weight are mixed, adopt the mixture that adopts activated alumina, thorium oxide, chromium oxide various metal oxides to make catalyst, reaction temperature is 400 ℃, reaction pressure 4.5.0MPa, space velocity is 800h-1, see details figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com