Electrochemical method for preparing silver halide photocatalytic material

A technology of silver halide and composite materials, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems that have not been reported, and achieve simple preparation methods, Excellent catalytic activity, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

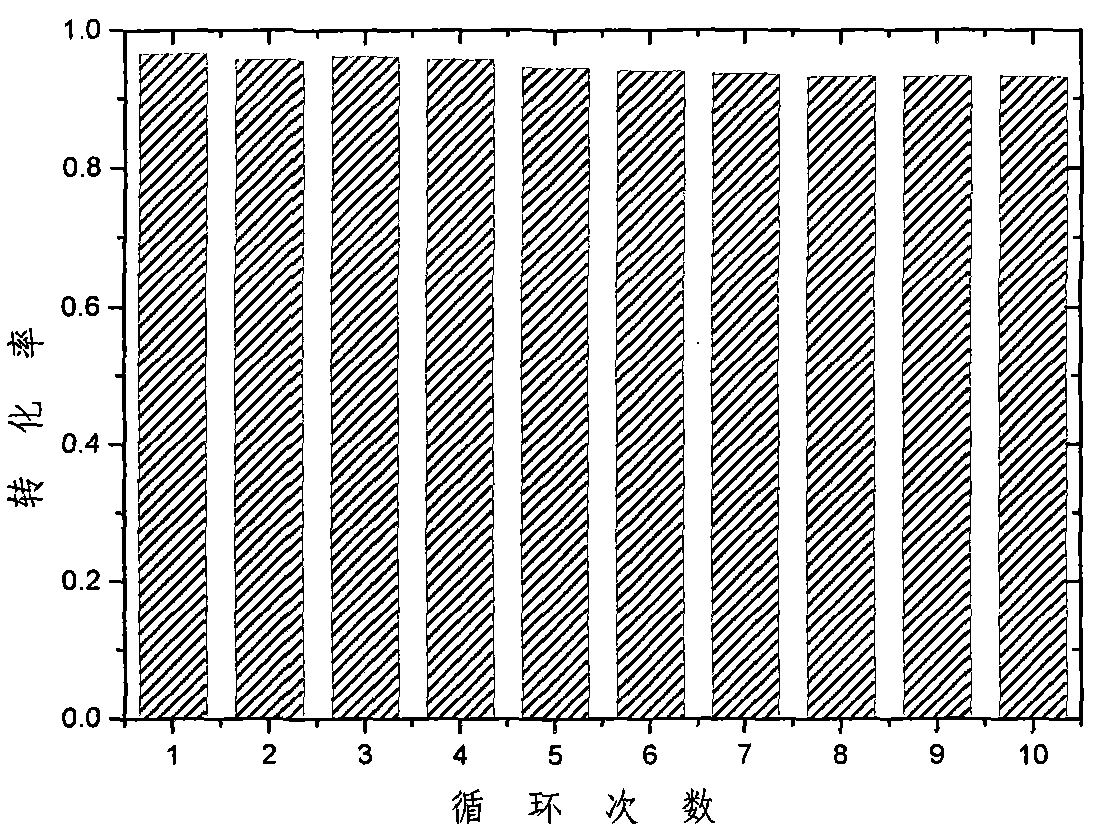

[0016] Configure 0.5M KBr solution and use it as the electrolyte, and use silver sheet, silver / silver chloride, and silver wire as the working electrode, reference electrode, and counter electrode for electrolysis. Wherein the electrode potential is controlled at 3.2V. After the electrolysis, the silver sheet deposited with silver bromide is placed in a beaker filled with double distilled water, placed in an ultrasonic cleaning tank, and ultrasonicated until the surface of the silver sheet turns silvery white completely. The silver flakes were removed and the resulting silver bromide was filtered, washed and dried. Weigh 0.09g silver bromide powder, join in the methyl orange solution of 15ml, carry out irradiation under visible light 15 minutes, methyl orange degrades completely, repeats 10 times, this catalyst still has stable photocatalytic degradation performance, figure 1 The data of the catalyst degrading methyl orange solution for 10 cycles are given in .

Embodiment 2

[0018] Configure 2.0M NaCl solution, then disperse graphene oxide into the solution, and use the composite solution as the electrolyte, and use silver sheet, silver / silver chloride, and silver wire as the working electrode, reference electrode and counter electrode respectively , for electrolysis. The electrode potential was controlled at 3.0V, and ultrasound was applied synchronously during the electrolysis process. After the electrolysis, the silver chloride / graphene oxide composite material obtained was filtered, washed and dried, and stored in the dark for later use.

Embodiment 3

[0020] Configure 1.0M KI solution, then disperse polypyrrole into the solution, and use the composite solution as the electrolyte, and use silver sheet, silver / silver chloride, and silver wire as the working electrode, reference electrode and counter electrode respectively, Perform electrolysis. The electrode potential was controlled at 2.0V, and ultrasound was applied synchronously during the electrolysis process. After the electrolysis, the silver iodide / polypyrrole composite material obtained was filtered, washed and dried, and stored in a dark and dry environment until use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com