Compound silicon-free long nozzle and manufacturing method thereof

A manufacturing method and shroud technology, applied in the direction of manufacturing tools, casting equipment, casting molten material containers, etc., can solve the problems such as the reduction of anti-scouring performance, so as to ensure mechanical strength, prevent the reduction of anti-erosion and anti-scouring performance, and effectively effect on purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment.

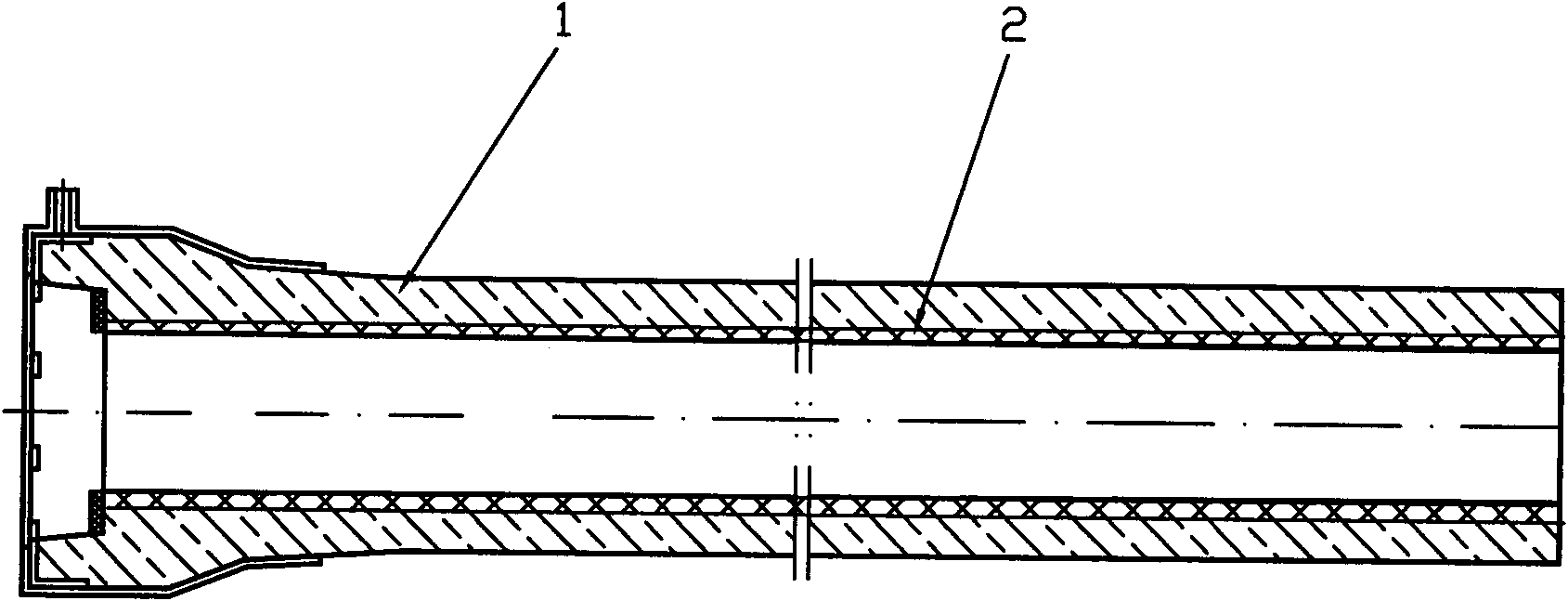

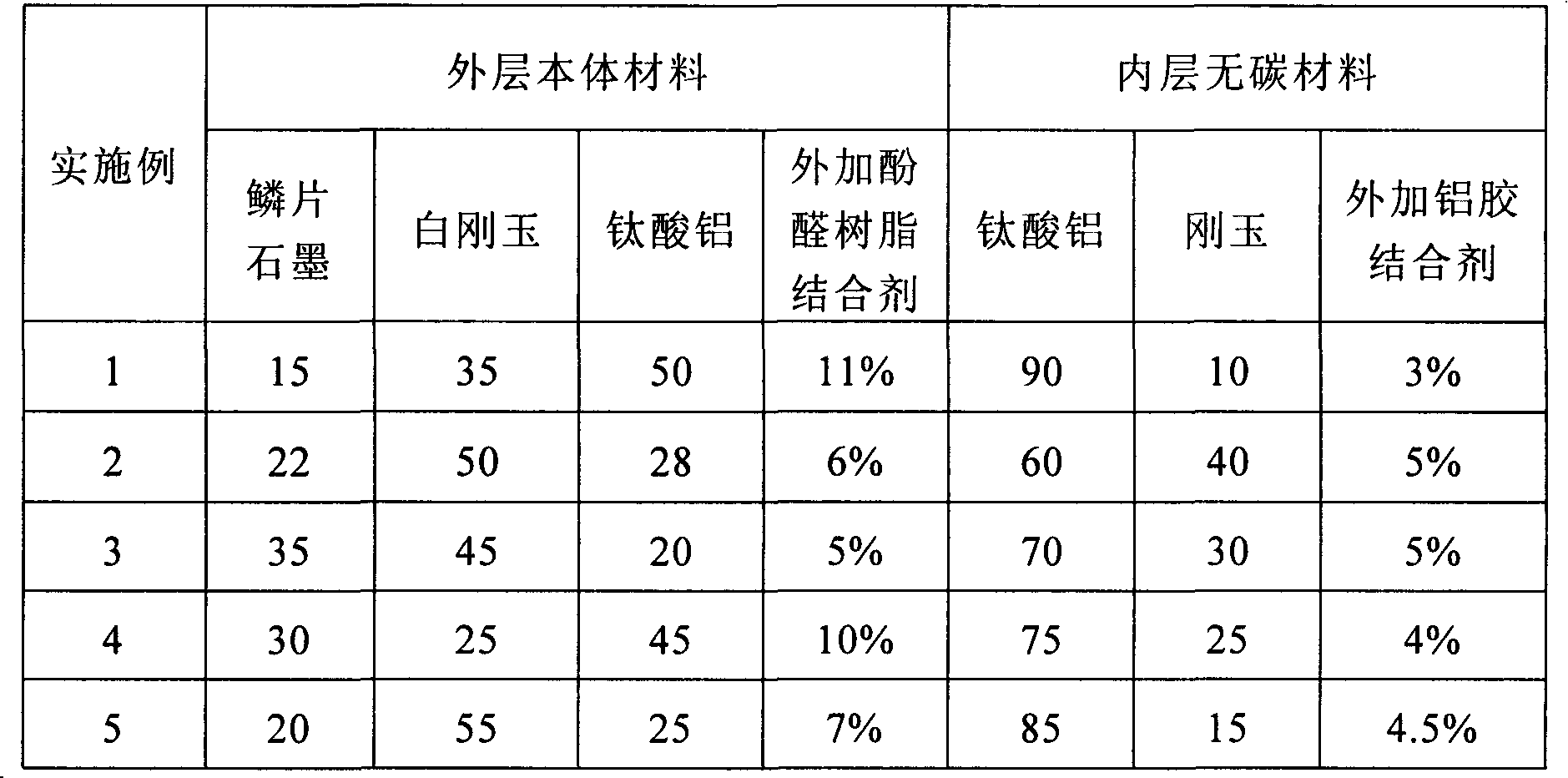

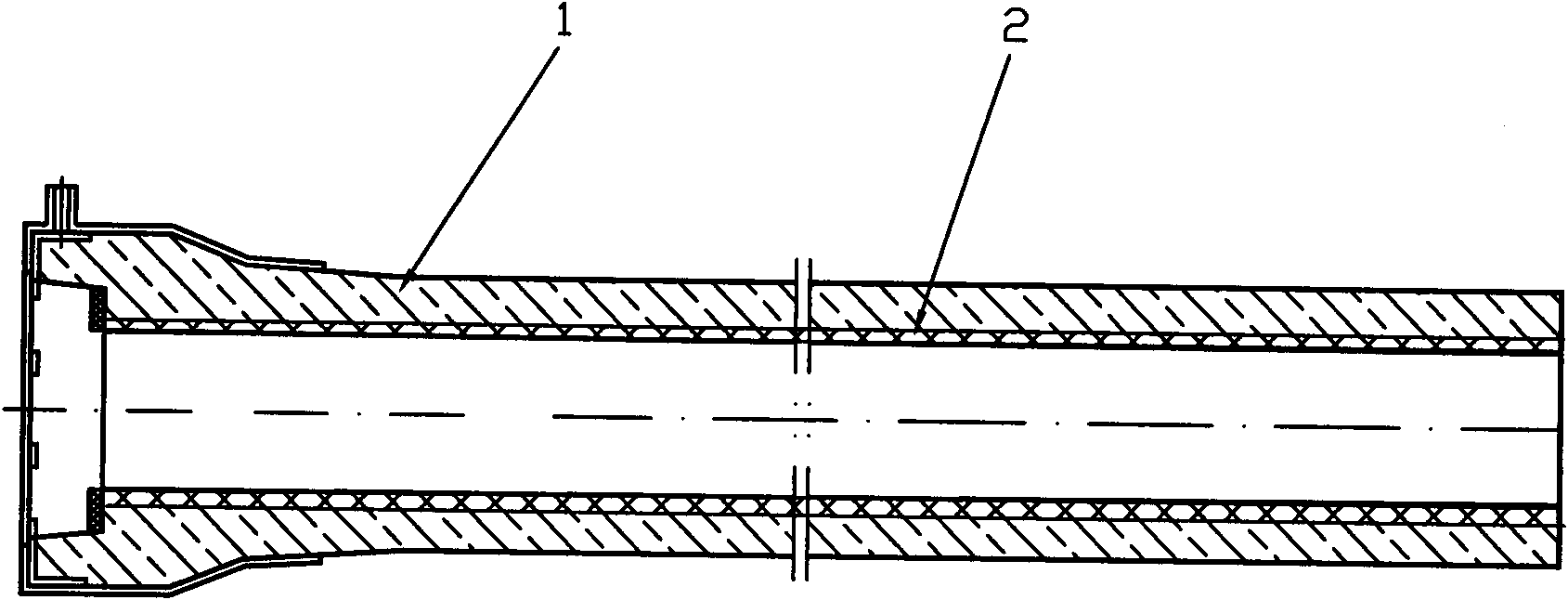

[0024] see figure 1 , the composite non-silicon long nozzle of the present invention, comprises, outer body 1, its material component weight percent is: 15~35%, white corundum 35~55%, aluminum titanate 20~50%, add phenolic resin binder 8-10%; the inner layer 2, the weight percentage of its material components is: aluminum titanate 60-90%, corundum 10-40%, plus aluminum adhesive 3-5%;

[0025] During manufacture, the material of the outer body 1 and the carbon-free material of the inner layer 2 are uniformly mixed respectively, and 8-10% of the phenolic resin binder is added to the above-mentioned components to the outer layer material, and the raw materials are granulated by a granulator. The granulated material is dried on the drying bed to make it meet the molding requirements; add 3 to 5 aluminum glue to the inner layer material and stir evenly for use; add the inner layer materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com