Water-soluble dye and preparation method and application thereof

A technology of water-soluble dyes and nanomaterials, applied in the preparation of azo dyes, dyeing methods, azo dyes, etc., can solve the problems of poor color fastness to heat and light, low chemical stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

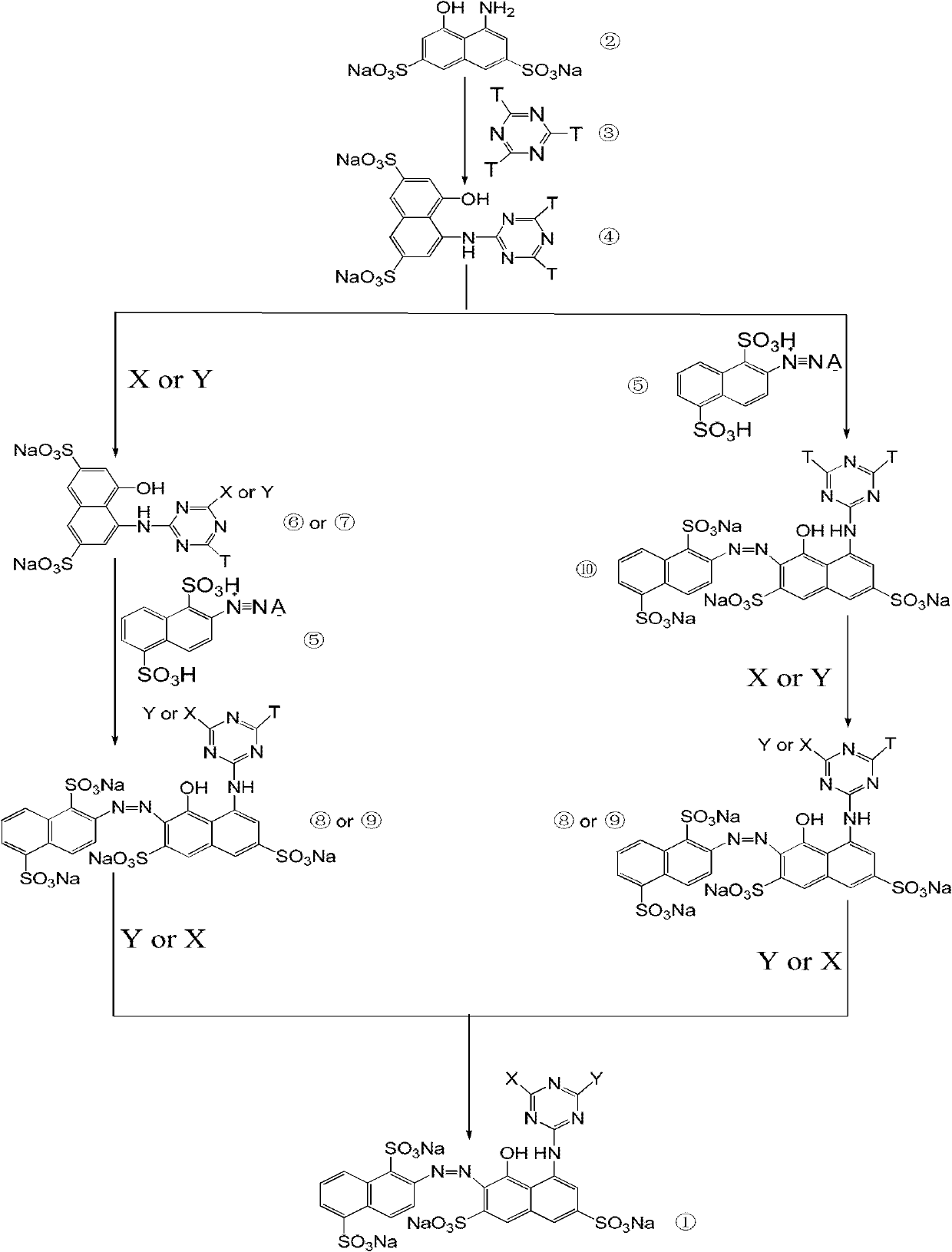

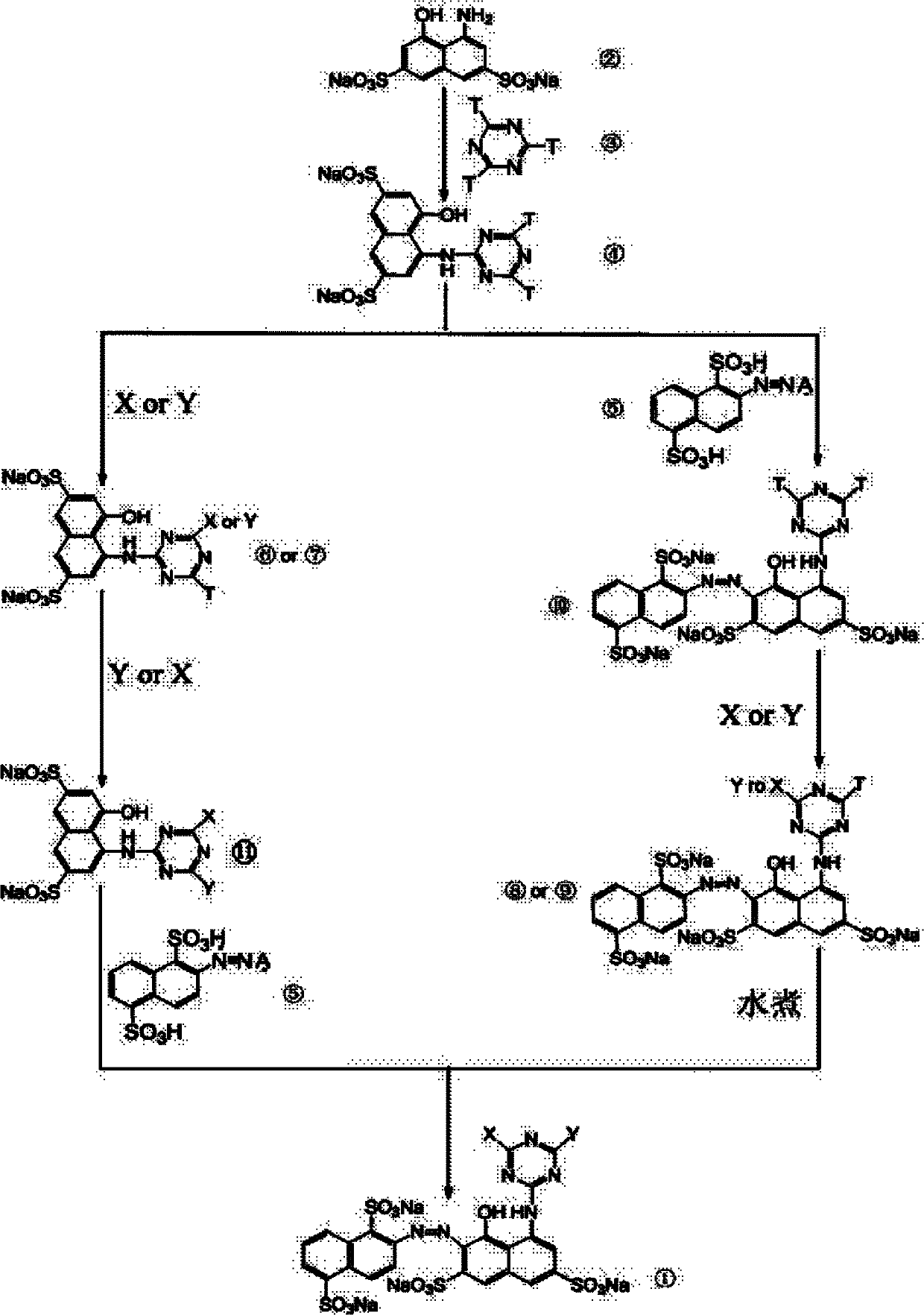

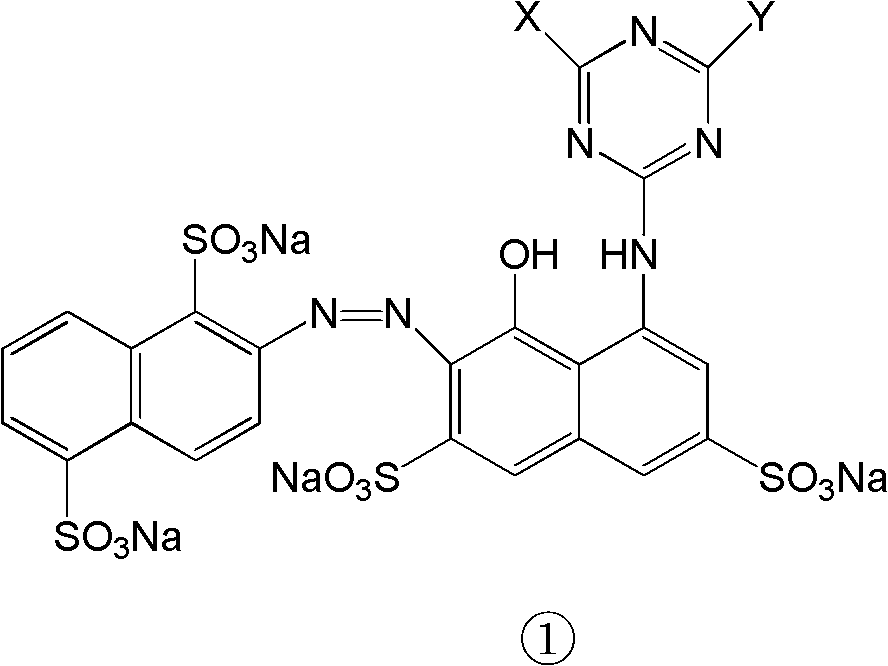

[0135] Embodiment 1 (with the first kind of preparation general formula 1. the synthetic method of water-soluble dyestuff (with reference to figure 1 Left side reaction route) preparation product 1)

[0136] a) Add 20g of water, 0.4g of wetting agent and 30g of ice into a 500mL reaction bottle, control the temperature at -5-5°C with an ice-salt bath, and stir rapidly; then add 9.6g of cyanuric chloride, and stir rapidly for 30 minutes , grind cyanuric chloride in ice-water mixture to obtain cyanuric chloride solution, control the temperature at -5~5°C; Mix the cyanuric chloride solution evenly;

[0137] b) Add 27.5g of water and 1.8g of NaHCO to a 100mL beaker 3 and 15.9g of 1-amino-8-naphthol-3,6-disulfonic acid of formula ②, stir well; then add NaHCO carefully 3 Adjust the pH to 6.5-7.5, stir until the 1-amino-8-naphthol-3,6-disulfonic acid of formula ② is completely dissolved, add a small amount of defoamer to defoam; add 20g of ice to it and cool down to 0~ 5 DEG C, ob...

Embodiment 2-14

[0155] As in Example 1, all the other steps are the same, and the p-aminobenzenesulfonic acid in step h) is replaced with m-aminobenzenesulfonic acid, anthranilic acid, aniline, p-phenylenediamine, 2,5-disulfonic acid aniline, 2,5-Diaminobenzenesulfonic acid, aminomethanesulfonic acid, glycine, ammonia water, ethanolamine or diethanolamine, can obtain the water-soluble dye products 2-14 with the general formula ①, see Table 1 for details. Selectively list the liquid color difference of several products as follows:

[0156] Dye name Liquid color difference Remarks

[0157] D. L Da Db D C D. E D. H

[0158] Water-soluble dye 2 than standard sample blue

[0159] -0.315 -0.379 -1.016 -0.112 1.129 -1.079

[0160] D. L Da Db D C D. E D. H

[0161] Water-soluble dye 3 than standard sample blue

[0162] -0.267 -0.284 -0.970 -0.033 1.045 -1.010

[0163] D. L D...

Embodiment 15

[0172] Embodiment 15 (use the synthetic method of the 4th kind of preparation general formula ① water-soluble dyestuff)

[0173] Add 20g of water, 0.4g of wetting agent and 30g of ice into a 500mL reaction bottle, control the temperature at -5~5°C with an ice-salt bath, and stir rapidly; then add 9.6g of cyanuric chloride, stir rapidly for 30 minutes, and Grind cyanuric chloride in the water mixture, and control the temperature at -5~5°C;

[0174] In a 100mL beaker, add 27.5g water, 1.8g NaHCO 3and 15.9g of 1-amino-8-naphthol-3,6-disulfonic acid of formula ②, stir well; then add NaHCO carefully 3 Adjust the pH to 6.5-7.5, stir until the 1-amino-8-naphthol-3,6-disulfonic acid of formula ② is completely dissolved, add a small amount of defoamer to defoam; add 20g of ice to it and cool down to 0~ 5°C; then add 0.70g rutile nano-titanium oxide and cyanuric chloride solution and mix evenly;

[0175] Add the 1-amino-8-naphthol-3,6-disulfonic acid solution of the above-mentioned p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com