Metal-nanoparticle-doped oxide luminescent material with hollow structure and preparation method thereof

A metal nanoparticle and hollow structure technology, which is applied in the field of oxide luminescent materials doped with metal particles and its preparation, can solve the problems of low luminous efficiency and attenuation, and achieve the effects of industrial production, simple operation, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

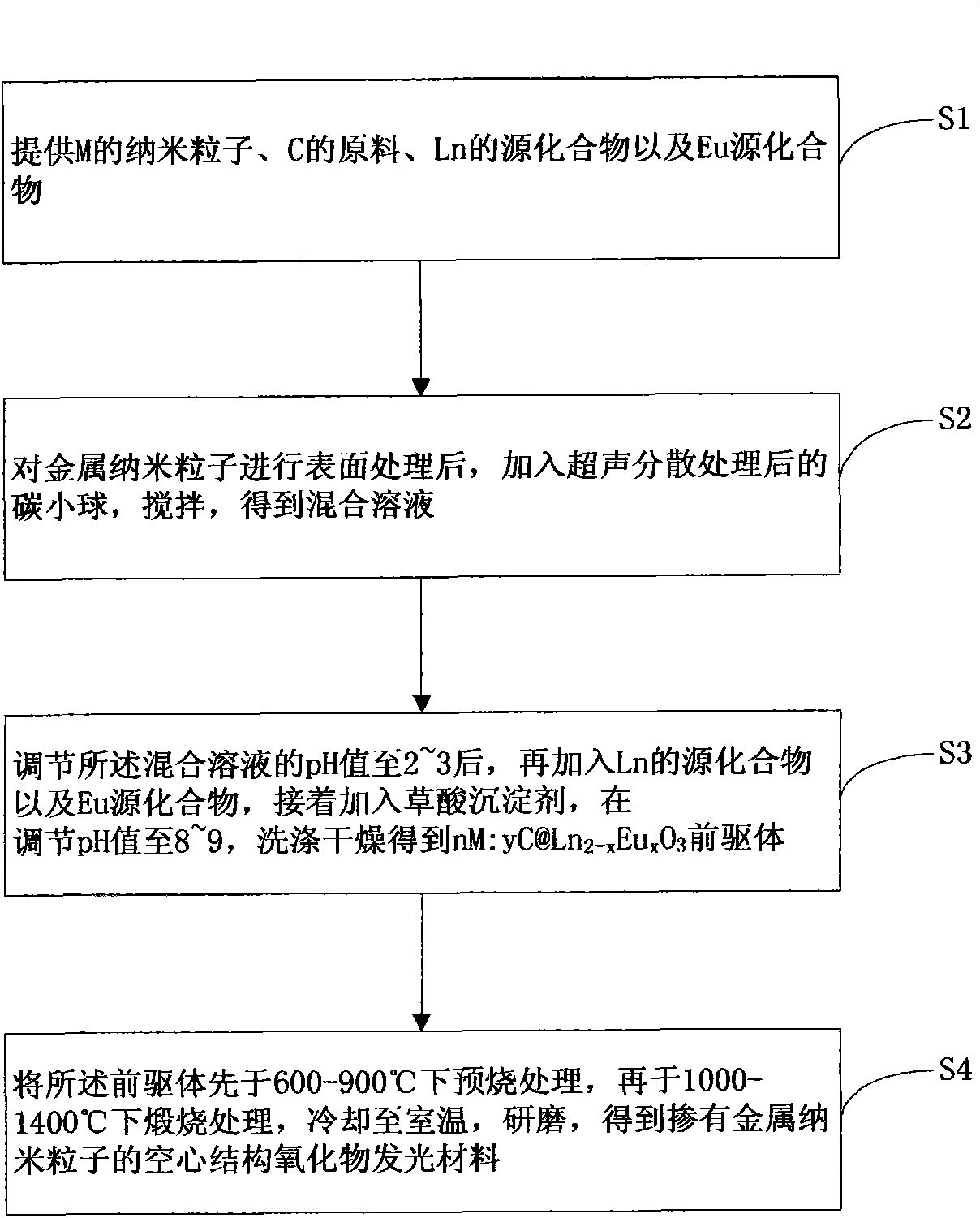

[0031] A method for preparing a hollow structure oxide luminescent material doped with metal nanoparticles, such as image 3 shown, including the following steps:

[0032] S1, according to the chemical formula nM:yCLn 2-x Eu x o 3 The stoichiometric ratio of each element in, weigh the nanoparticles of M, the raw material of C, the source compound of Ln and the source compound of Eu; wherein, M is one of Ag, Au, Pt, Pd, Cu nanoparticles, and Ln is One of Gd, Y, La, Lu, C is carbon spheres, the value range of x is 02-x Eu x o 3 The molar ratio of n is 0-3 , y is C and Ln 2-x Eu x o 3 The molar ratio of y, the value of y is 0<y≤1;

[0033]S2. Add the nanoparticles of M to an aqueous solution containing polyvinylpyrrolidone (PVP, the same below) surface treatment agent for surface treatment, then add the raw material of C after ultrasonic dispersion treatment, and stir to obtain a mixed solution;

[0034] S3. After adjusting the pH value of the mixed solution to 2-3, add ...

Embodiment 1

[0047] Embodiment 1 prepares 5 * 10 -5 Au:CGd 1.99 Eu 0.01 o 3 Luminescent material

[0048] Weigh 1g of PVP and dissolve it in 5mL of deionized water, then add 0.25ml to it to a concentration of 1×10 -3 mol / L metal Au nanoparticles, magnetically stirred for 24 hours, ready for use;

[0049] Weigh 15 mg of the prepared carbon pellets, ultrasonically separate them for 15 minutes, mix the above-mentioned surface-treated metal Au solution with this solution, and stir evenly;

[0050] Use nitric acid solution to adjust the pH value of the above solution to 2-3, and then add 0.5mol / L Gd to the above solution according to the stoichiometric ratio 3+ Ion 19.9ml, 0.5mol / L Eu 3+ Ion 0.1ml, stir evenly, slowly add 18ml of oxalic acid solution with a concentration of 1mol / L (20% excess molar ratio), gradually form a white precipitate, use ammonia water to adjust the pH to 8-9, continue to stir for 3h, age and filter , washing, and drying to obtain the precursor.

[0051] The prec...

Embodiment 2

[0052] Embodiment 2 prepares 5 * 10 -4 Ag:CGd 1.9 Eu 0.1 o 3 Luminescent material

[0053] Weigh 1g of PVP and dissolve it in 5mL of deionized water, then add 2.5ml to it to a concentration of 1×10 -3 mol / L metal Ag nanoparticles, magnetic stirring for 24h;

[0054] Weigh 30 mg of prepared carbon pellets, ultrasonically separate them for 15 minutes, mix the above-mentioned surface-treated metal Ag solution with this solution, and stir evenly;

[0055] Use nitric acid solution to adjust the pH value of the above solution to 2-3, and then add 0.5mol / L Gd to the above solution according to the stoichiometric ratio 3+ Ion 19ml, 0.5mol / L Eu 3+ 1ml of ions, stir evenly, slowly add 18ml of oxalic acid solution with a concentration of 1mol / L (20% excess molar ratio), and gradually form a white precipitate, adjust the pH value to 8-9 with ammonia water, continue stirring for 3h, age, filter, Wash and dry to obtain the precursor.

[0056] The precursor was calcined at 800°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com