Anisotropic nanometer press-in test table of biological soft tissues and method for performing nanometer press-in experiment by using anisotropic nanometer press-in test table

A biological soft tissue and nano-indentation technology, applied in the field of nano-indentation experiment and anisotropic nano-indentation test bench of biological soft tissue, can solve the problem that the biological activity of the material cannot be well guaranteed for a long time, the water loss of the tested surface, and the impact Experiment reliability and other issues, to achieve the effect of improving the efficiency of detection experiments, avoiding water loss, and improving the reliability of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

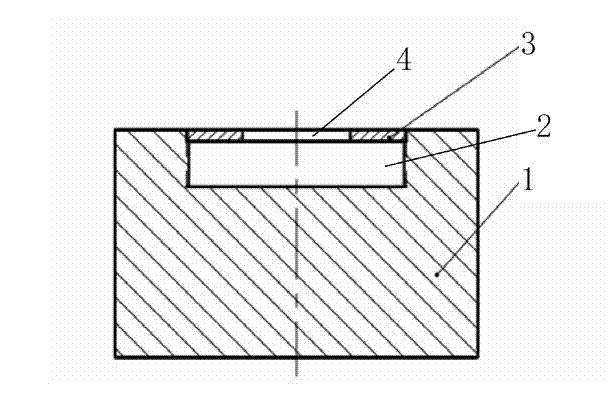

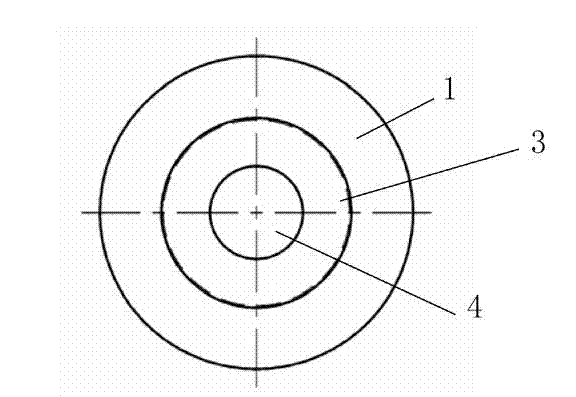

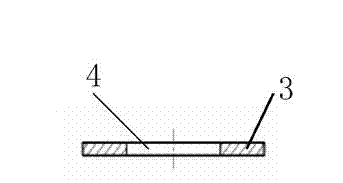

example 1

[0032] The test material is a large piece of cartilage on the lamb leg bone plate. The pressing direction is perpendicular to the natural surface of the cartilage. The test material is cut into a 15mm diameter disc as a test sample, and a drop of moisturizing solution is dropped into the holding hole 2 of the test platform. , spread the test sample on the bottom of the storage hole 2, drop a drop of solution, then use the screw cap body 3 with a round hole observation window 4 to press the test sample, and adjust the screw cap body 3 with a dropper through the observation window 4 The height of the inner solution, and then put the whole test bench into the card stage of the nanoindenter. The indenter used for indentation is the Flat end cone indenter produced by Agilent, the surface proximity sensitivity coefficient is 40%, and the indentation depth is 5000nm. The obtained results are as follows Figure 9 shown.

Embodiment 2

[0034]The test material is a large piece of cartilage on the bone plate of the leg of lamb. The pressing direction is perpendicular to the longitudinal cutting surface of the natural surface of the cartilage. The test material is cut into 6mmX15mm strip-shaped slices with a microtome as the test sample. Drop a drop of moisturizing solution into the hole 2, spread the test sample on the bottom of the storage hole 2, drop another drop of solution, then use the screw cap body 3 with a rectangular observation window 4 to press the test sample, and pass through the observation window 4 Use a dropper to adjust the height of the solution in the screw cap body 3, and then install the whole test platform on the card platform of the nanoindentation instrument. The indenter used for indentation is the Flat end cone indenter produced by Agilent, the surface proximity sensitivity coefficient is 40%, and the indentation depth is 5000nm. The obtained results are as follows Figure 10 shown. ...

Embodiment 3

[0036] The test material is bovine cardiovascular, and the pressing direction is perpendicular to the inner surface of the heart tube. The test material is cut into a 15mm diameter disc as a test sample. Since the heart tube is thin, a non-porous aluminum sheet with a thickness of 2mm is used as a gasket before spinning. Put the heart tube sample into the holding hole 2, drop a drop of moisturizing solution into the holding hole 2 of the detection platform, spread the test sample on the bottom of the holding hole 2, and then drop a drop of the solution, Then use the screw cap body 3 with a circular observation window 4 to press the test sample, adjust the height of the solution in the screw cap body 3 through the observation window 4 with a dropper, and then put the whole test platform into the card platform of the nanoindentation instrument . The indenter used for indentation is the Flat end cone indenter produced by Agilent, the surface proximity sensitivity coefficient is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com