Production process and device for monotone purely inorganic artificial marble quarry stone

A technology of artificial marble and production technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of low stone strength, high price, and shortage of supply, and achieve the effects of reducing porosity, increasing compactness, and improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

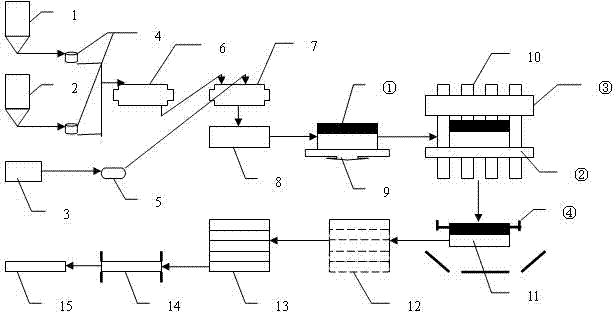

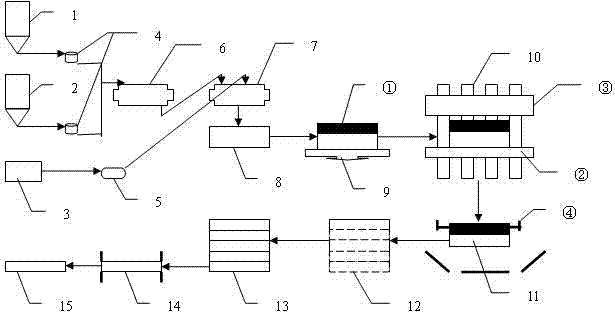

Method used

Image

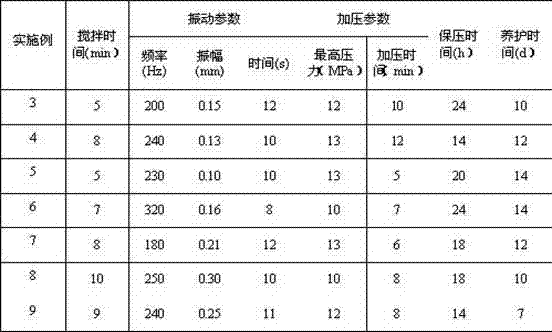

Examples

Embodiment 1

[0050] Example 1 Imitation Turkish white sand beige marble

[0051] 1. Select pure white and non-variety marble chips for crushing, grinding and screening.

[0052] 2. Mix according to the proportion of 100 mesh accounting for 60% (mass fraction, the same below), 200 mesh accounting for 25%, and 325 mesh accounting for 15% to make graded stone powder.

[0053] 3. According to the proportion of graded stone powder accounting for 70%, 42.5 grade white cement accounting for 29%, and titanium dioxide accounting for 1%, the graded stone powder is mixed with white cement and titanium dioxide. To obtain dry material, the mixing time is not less than 5 minutes.

[0054] 4. Weigh industrial aluminum sulfate, dissolve it in water, and prepare an aluminum salt solution with a mass concentration of 2.5%.

[0055] 5. Put the dry material obtained in step (3) into the wet mixer 7, and pump the aluminum salt solution 3 into the wet mixer 7 for wet mixing. The dosage of the aluminum salt...

Embodiment 2

[0065] Example 2 Imitation Beijing white marble marble

[0066] 1. Select pure white and non-variety marble chips for crushing, grinding and screening.

[0067] 2. Mix 10% of 20 mesh (mass fraction, the same below), 60% of 60 mesh, 25% of 100 mesh, and 5% of 325 mesh to make graded stone powder.

[0068] 3. According to the proportion of graded stone powder accounting for 60%, 42.5 grade white cement accounting for 39.8%, and azurite pigment 0.02%, mix graded stone powder with white cement and azurite pigment. The mixing time is not less than 5 minutes.

[0069] 4. Weigh industrial aluminum chloride, dissolve it in water, and prepare an aluminum salt solution with a mass concentration of 4%.

[0070] 5. Put the dry material obtained in step (3) into the wet mixer 7, and pump the aluminum salt solution 3 into the wet mixer 7 for wet mixing. The amount of aluminum salt solution is 32% of the dry material weight, and the mixing time is not less than 5 minutes.

[0071] 6. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com