Method for producing water class with high mole ratio by coal gangue acid-leaching residue

A high modulus water glass, acid leaching slag technology, applied in the removal of silicate, alkali metal silicate, solid waste, etc. Good, guarantee the yield of silicon, guarantee the effect of washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

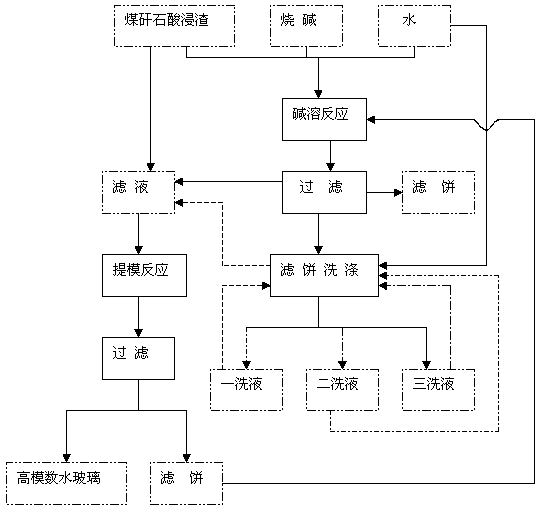

Image

Examples

Embodiment 1

[0032] Example 1: Take Al 2 o 3 , SiO 2 Acid slag with a mass content of 3.67% and 81.32% was used as raw material.

[0033] 1. The first alkali solution

[0034]Set the alkali solution reaction to water glass modulus of 2, take 2000g of acid residue in a 10000ml three-necked flask, add 2168g of alkali and 3832g of water to make a solution with a liquid-solid ratio of 3:1, and put the three-necked flask into a water bath Inside, control the temperature in the three-necked flask to 95°C, react under normal pressure for 1h, filter while hot, replace with 1000ml of water, incorporate into the filtrate, and wash the filter cake three times with 9000ml of water. The first lotion is used for the next alkali preparation, the second lotion is used for the insufficient part, and the rest is used for the next alkali solution washing. Obtain filtrate 5210ml, weight is 6148g, is 2.41 after analyzing filtrate water glass modulus, SiO 2 The content is 1351g, and the dissolution rate ...

Embodiment 2

[0042] Example 2 : Take Al 2 o 3 , SiO 2 Acid slag with a mass content of 6.0% and 83.7% was used as raw material.

[0043] 1. The first alkali solution

[0044] Set the alkali-dissolving reaction to water glass modulus of 2, take 2000g of acid slag in a 10000ml three-necked flask, add 2232g of alkali and 4768g of water to make a solution with a liquid-solid ratio of 3.5:1, and put the three-necked flask into a water bath Inside, control the temperature in the three-necked flask to 92°C, react for 1.5h, filter while hot, replace with 1000ml of water, incorporate into the filtrate, and wash with 9000ml of water three times. The first lotion is used for the next alkali preparation, the second lotion is used for the insufficient part, and the rest is used for the next alkali solution washing. Obtain filtrate 6310ml, weight is 7005g, is 2.12 through analysis filtrate water glass modulus, SiO 2 The content is 1410g, and the dissolution rate of silicon is 84.2%.

[0045] 2. ...

Embodiment 3

[0052] Example 3 : Take Al 2 o 3 , SiO 2 Acid slag with a mass content of 7.8% and 75% was used as raw material.

[0053] 1. The first alkali solution

[0054] Set the alkali solution reaction to water glass modulus of 2, take 2000g of acid residue in a 10000ml three-necked flask, add 2000g of alkali and 6000g of water to make a solution with a liquid-solid ratio of 4:1, and put the three-necked flask into a water bath Inside, control the temperature in the three-necked flask to 90°C, react for 2.0 hours, filter while hot, replace with 1000ml of water, incorporate into the filtrate, and wash with 9000ml of water three times. The first lotion is used for the next alkali preparation, the second lotion is used for the insufficient part, and the rest of the lotion is used for the next alkali solution washing. Obtain filtrate 7750ml, weight is 8835g, is 2.20 through analysis filtrate water glass modulus, SiO 2 The content is 1278g, and the dissolution rate of silicon is 85.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com