Method for producing high-purity isoborneol

An isoborneol and high-purity technology, applied in the field of producing high-purity isoborneol, can solve the problems of large amount of camphene, high cost, large centrifugal workload, etc., and achieves less amount of camphene, low cost, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

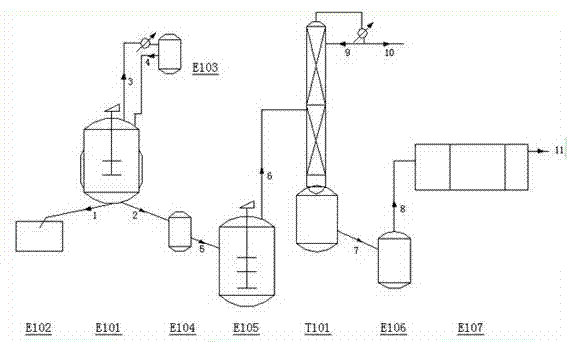

Image

Examples

Embodiment 1

[0022] (1) Saponification reaction: The isobornyl acetate with a content of ≥97% produced by the esterification of camphene and acetic acid is pumped to the saponification reactor E-101, and a 30% sodium hydroxide solution is added to ≥98% xylene, feed isobornyl acetate: sodium hydroxide solution: xylene = 4:3:1, heat up to 150°C, and control the pressure at 0.30MPa. After reacting for 8 hours, take a sample for analysis. The reaction can be stopped if the bornyl ester content is ≤0.5%, and the cooling water is passed into the jacket of the saponification reaction kettle to cool down the temperature of the feed liquid.

[0023] (2) Water washing: add 10% sodium acetate solution into saponification reactor E-101, stir for 5 minutes, let it stand for 5 minutes, then enter 80% sodium acetate solution into water washing tank E-102, and wash until pH=7.

[0024] (3) Dehydration: Stir the feed liquid in the saponification reactor E-101 and raise the temperature to 120°C. Water and x...

Embodiment 2

[0028] (1) Saponification reaction: Isobornyl acetate with a content ≥ 97% generated by the esterification reaction of camphene and acetic acid is pumped to the saponification reactor E-101, and sodium hydroxide solution with a mass fraction of 46% is added. ≥98% xylene, according to isobornyl acetate: sodium hydroxide solution: xylene = 4.2:3.5:1 feed, temperature rises to 155°C, pressure is controlled at 0.35MPa, after 10 hours of reaction, sampling analysis, acetic acid iso The reaction can be stopped if the bornyl ester content is ≤0.5%, and the cooling water is passed into the jacket of the saponification reaction kettle to cool down the temperature of the feed liquid.

[0029] (2) Washing: Add 15% sodium acetate solution into saponification reactor E-101, stir for 5 minutes, let it stand for 10 minutes, then enter 85% sodium acetate solution into water washing tank E-102, and wash until pH=7-8.

[0030] (3) Dehydration: Stir the feed liquid in the saponification reactor ...

Embodiment 3

[0034] (1) Saponification reaction: Isobornyl acetate with a content of ≥97% produced by the esterification of camphene and acetic acid is pumped to the saponification reactor E-101, and sodium hydroxide solution with a mass fraction of 38% is added. ≥98% xylene, according to isobornyl acetate: sodium hydroxide solution: xylene = 4.1:3.2:1 feed, temperature rises to 152°C, pressure is controlled at 0.32MPa, after 9 hours of reaction, sampling analysis, acetic acid iso The reaction can be stopped if the bornyl ester content is ≤0.5%, and the cooling water is passed into the jacket of the saponification reaction kettle to cool down the temperature of the feed liquid.

[0035] (2) Washing: add 12% sodium acetate solution into the saponification reactor E-101, stir for 5 minutes, let it stand for 8 minutes, enter the 83% sodium acetate solution into the washing tank E-102, and wash until pH=7-8.

[0036] (3) Dehydration: Stir the feed liquid in the saponification reactor E-101 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com