Preparation method of high purity superfine ferrous oxalate

A technology of ferrous oxalate and ferrous sulfate, applied in the direction of carboxylate preparation, etc., to achieve the effect of simple process, narrow particle size distribution range, and easy industrialized large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

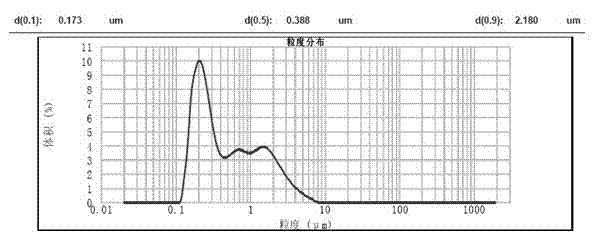

Image

Examples

Embodiment 1

[0025] (1) Dissolve 70g of industrial-grade oxalic acid in 700ml of deionized water under the action of mechanical stirring, completely dissolve 156g of industrial-grade ferrous sulfate in 320ml of deionized water under the action of mechanical stirring, and vacuum the obtained solution Remove impurities by suction filtration;

[0026] (2) Spray the purified ferrous sulfate solution into the oxalic acid solution with a dispersant (a mixture of sodium polyacrylate, methanol, ethanol and propanol) under the action of a high-speed centrifugal sprayer. The amount of dispersant added is the same as that of oxalic acid The solution ratio is 0.001mol / L until the molar ratio of ferrous sulfate and oxalic acid in the solution reaches 1:1;

[0027] (3) The reaction temperature of the sprayed ferrous sulfate solution and oxalic acid solution is always controlled at 20°C, and the two react for 10 minutes under the action of ultrasonic cavitation at an ultrasonic frequency of 40kHz to obta...

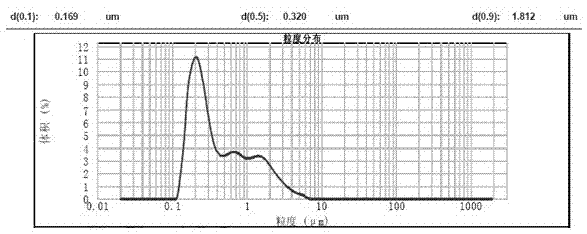

Embodiment 2

[0030] (1) Completely dissolve 70g of industrial grade oxalic acid in 180ml of deionized water under the action of mechanical stirring, completely dissolve 156g of industrial grade ferrous sulfate in 300ml of deionized water under the action of mechanical stirring, and vacuum the obtained solution Remove impurities by suction filtration;

[0031] (2) Spray the purified ferrous sulfate solution into the oxalic acid solution with ethanol dispersant under the action of a high-speed centrifugal sprayer. The ratio of the dispersant to the oxalic acid solution is 0.09 mol / L until the solution The molar ratio of ferrous sulfate to oxalic acid reaches 1:1;

[0032] (3) The reaction temperature of the sprayed ferrous sulfate solution and oxalic acid solution was always controlled at 0°C, and the two reacted for 10 minutes under the action of ultrasonic cavitation at an ultrasonic frequency of 40kHz to obtain a ferrous oxalate suspension;

[0033] (4) Leave the ferrous oxalate suspensi...

Embodiment 3

[0035] (1) Dissolve 70g of industrial grade oxalic acid in 180ml of deionized water under the action of mechanical stirring, completely dissolve 156g of industrial grade ferrous sulfate in 300ml of deionized water under the action of mechanical stirring, and use the obtained solution Remove impurities by vacuum filtration;

[0036] (2) Spray the purified ferrous sulfate solution into the oxalic acid solution with ethanol dispersant under the action of a high-speed centrifugal sprayer. The ratio of the dispersant to the oxalic acid solution is 0.1mol / L until the solution The molar ratio of ferrous sulfate to oxalic acid reaches 1:1;

[0037] (3) The reaction temperature of the sprayed ferrous sulfate solution and oxalic acid solution was always controlled at -20°C, and the two reacted for 10 minutes under the action of ultrasonic cavitation at an ultrasonic frequency of 59kHz to obtain a ferrous oxalate suspension;

[0038] (1) Leave the ferrous oxalate suspension to stand, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com