Preparation method of hydrogel for drug-loaded contact lens

A contact lens and hydrogel technology, applied in medical science, glasses/goggles, instruments, etc., can solve the problems of lower production efficiency, long polymerization time, high polymerization temperature, etc., and achieve great social and economic benefits, The effect of strong operability and simple synthesis route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

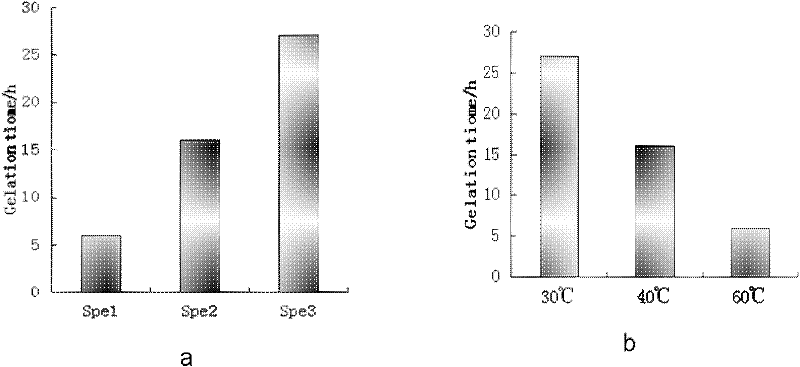

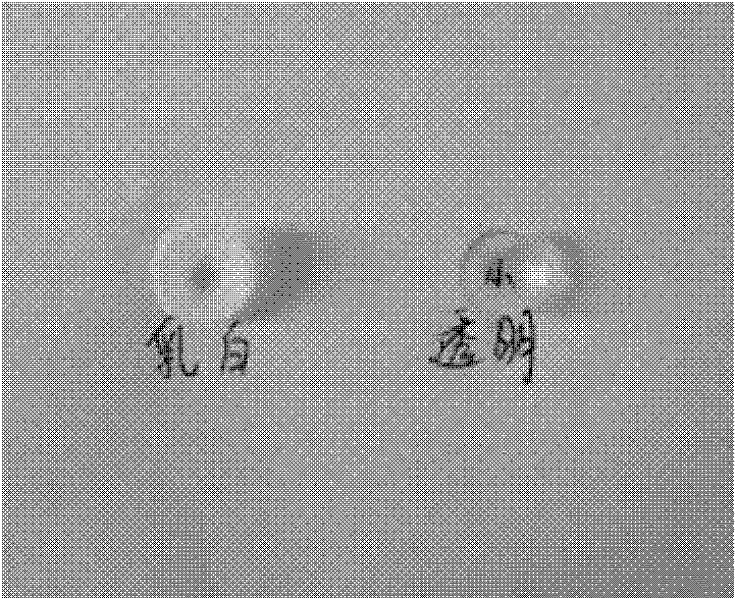

[0028] Take HEMA 4.7g, NVP 4.7g, add 1.2wt% APS aqueous solution and 0.6wt% TEMED aqueous solution 1mL each, add norfloxacin or hyaluronic acid according to the ratio of 2mg / g monomer, mix well and put Polymerize at 60°C for a certain period of time and copolymerize in a circular mold to prepare a hydrogel. Observing reaction system by observation method becomes the time of hard, transparent film by liquid, i.e. polymerization time (the polymerization time of this example and other each embodiment see figure 1 ). After the polymerization is completed and demolded, it swells into a hydrogel in water.

Embodiment 2

[0030] Take HEMA 3.1g, NVP 6.3g, add 1.2wt% APS aqueous solution and 0.6wt% TEMED aqueous solution 1mL each, add norfloxacin or hyaluronic acid according to the ratio of 2mg / g monomer, mix well and put Hydrogels were prepared by copolymerization in a circular mold at 60°C for a certain period of time. Observe the time for the reaction system to change from a liquid to a hard, transparent film by observation, that is, the polymerization time. After the polymerization is completed and demolded, it swells into a hydrogel in water.

Embodiment 3

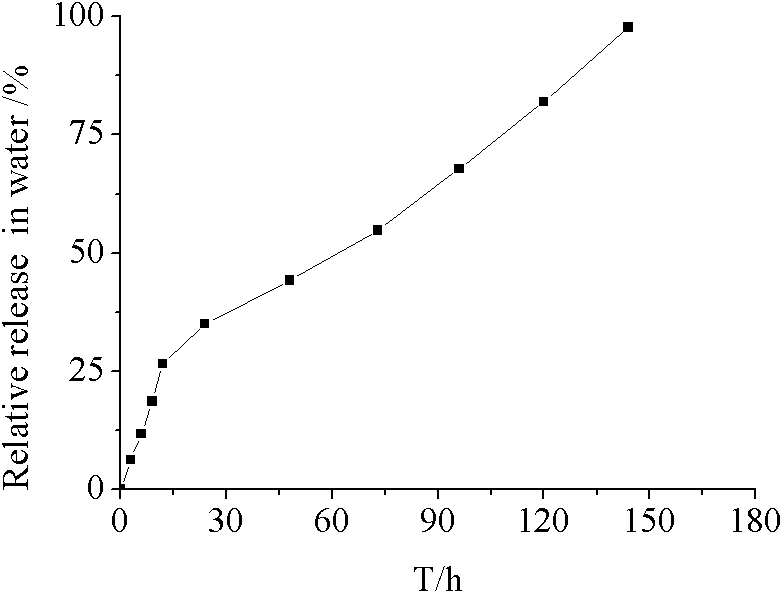

[0032] Take HEMA 7.4g, NVP 2g, add 1.2wt% APS aqueous solution and 0.6wt% TEMED aqueous solution 1mL each, add norfloxacin or hyaluronic acid according to the ratio of 2mg / g monomer, mix well and place in 60 Polymerize at ℃ for a certain period of time and copolymerize in a circular mold to prepare hydrogel. Observe the time for the reaction system to change from a liquid to a hard, transparent film by observation, that is, the polymerization time. After the polymerization is completed and demolded, it swells into a hydrogel in water. Put the prepared copolymer hydrogel in a 1.5ml centrifuge tube, add distilled water to 1.5ml, place the centrifuge tube at 37°C, and set the temperature at 3h, 6h, 9h, 12h, 1d, 2d, 3d, 4d respectively , 5d, 6d, and 7d were used to quantify the concentration of the drug (norfloxacin or hyaluronic acid) in the water by ultraviolet light to characterize the performance of drug sustained release.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com