Two-dimensional photonic crystal laser and manufacturing method

A technology of two-dimensional photonic crystals and manufacturing methods, which is applied in the direction of semiconductor lasers, lasers, phonon exciters, etc., can solve the problems of reduced resonator performance, incomplete refractive index periodic structure, and hole shape changes, etc., to improve freedom degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

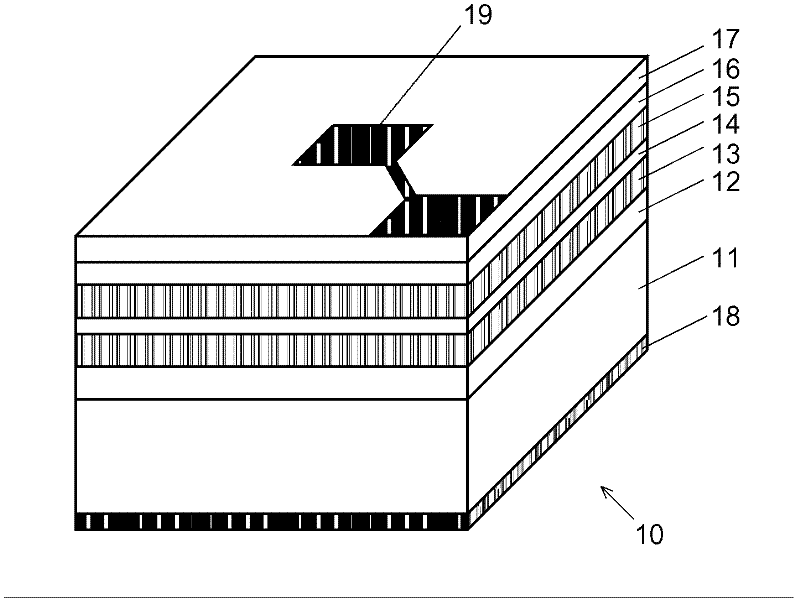

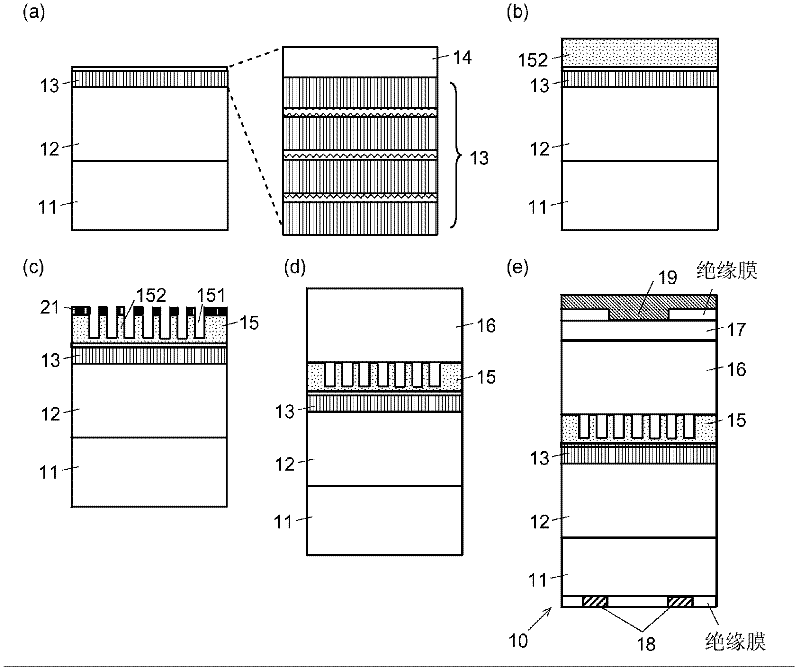

[0110] The two-dimensional photonic crystal laser 10 of embodiment 1 is as figure 1 As shown, a first cladding layer 12, an active layer 13, a carrier blocking layer 14, a two-dimensional photonic crystal layer 15, a second cladding layer (epitaxial growth layer) 16, and a contact layer are sequentially stacked on a substrate 11. 17 structures. In addition, a lower electrode 18 is provided under the substrate 11 , and an upper electrode 19 is provided on the contact layer 17 .

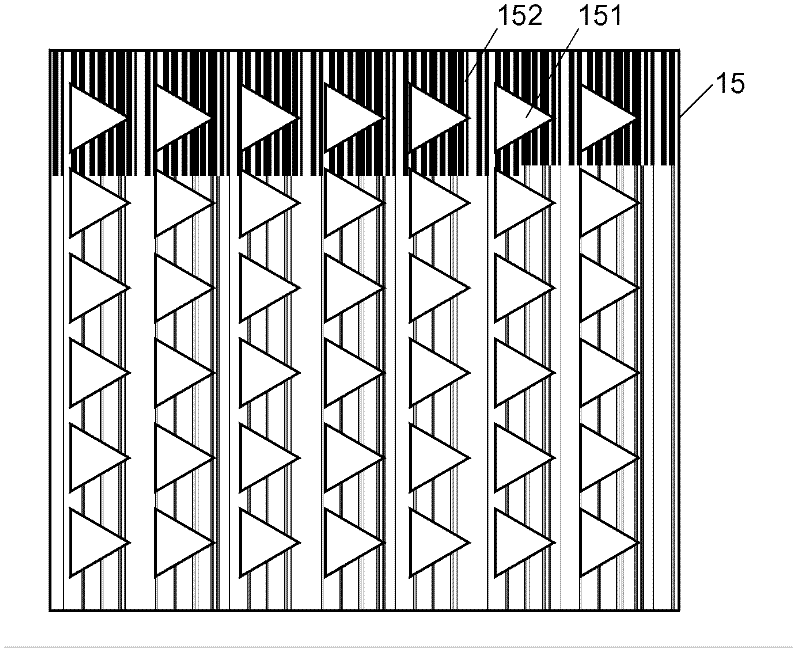

[0111] Two-dimensional photonic crystal layer 15 such as figure 2 As shown, cavities 151 having a planar shape such as a circle or a triangle are periodically formed in the plate-shaped base material layer 152 . In this embodiment, Al is used as the material of the base material layer 152 0.1 Ga 0.9 As. This is because this material is strong even at high temperatures, and the shape of the holes 151 will not be damaged even if the temperature is raised when the second cladding layer 16 is formed ...

Embodiment 2

[0120] use Figure 4 , Embodiment 2 of the two-dimensional photonic crystal laser of the present invention will be described. The two-dimensional photonic crystal laser 10A of this embodiment uses a two-dimensional photonic crystal layer 15A described below instead of the two-dimensional photonic crystal layer 15 of the first embodiment. Other configurations are the same as those of the two-dimensional photonic crystal laser 10 of the first embodiment.

[0121] The two-dimensional photonic crystal layer 15A has Al 0.65 Ga 0.35 The upper surface of the first base material layer 1521A of As (α=0.65) is thinner than that of the first base material layer 1521A. 0.1 Ga 0.9 The base material layer 152A having a two-layer structure of the second base material layer 1522A of As (α=0.1). In the base material layer 152A, the cavities 151A are formed in the same shape and period as in the first embodiment. The second base material layer 1522A has a lower Al content than the first b...

Embodiment 3

[0126] use Image 6 , Embodiment 3 of the two-dimensional photonic crystal laser of the present invention will be described. The two-dimensional photonic crystal laser 10B of the present embodiment is produced by using the two-dimensional photonic crystal laser manufacturing method of the first embodiment.

[0127] In the two-dimensional photonic crystal laser 10B, between the two-dimensional photonic crystal layer 15 and the second cladding layer 16 of Embodiment 1, a x Ga 1-x Re-grow interface layer 31 of As (0.4≦x Figure 7 ). For example, when the planar shape of the cavity 151 is a circle, the diameter corresponds to the maximum width; in the case of a regular triangle, the side length corresponds to the maximum width; The side length of the longest side is equal to the maximum width.

[0128] In this embodiment, by setting the Al content x of the regrown interface layer 31 to a relatively high value and setting the aspect ratio h / d to 1.3 or more, the raw material gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com