Adhesive special for inorganic insulation board

An inorganic thermal insulation board and adhesive technology, which is applied in the field of special adhesives for inorganic thermal insulation boards, can solve the problems of not being economical and practical, toxic, and highly toxic, and achieve the effects of low cost, small amount of addition, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Formula (expressed in parts by weight)

[0028] Powder formula:

[0029] Cement 300 Yellow Mortar 750

[0030] PFA 50 Polyester 2

[0031] Liquid formula

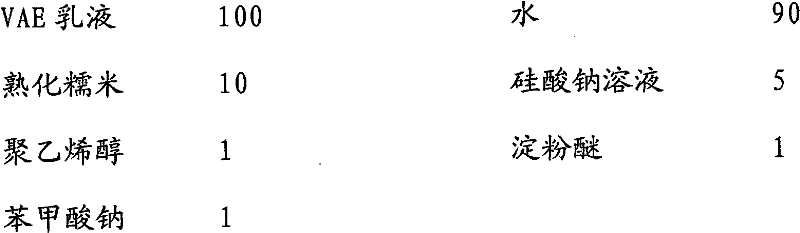

[0032]

[0033] 2. Preparation method

[0034] Grind the glutinous rice into 100 meshes, ripen it in 90 parts of hot water at 60°C, disperse it evenly in the preservative, and mix it with the liquid formula. The powder formula and the liquid formula are the powder by weight Formula: liquid material formula = 5: 1 for mixing, stirring at room temperature. After testing, the adhesive force of the present invention is 0.80 MPa.

Embodiment 2

[0036] 1. Formula (expressed in parts by weight)

[0037] Powder formula:

[0038] Cement 400 Yellow Mortar 600

[0040] Liquid formula

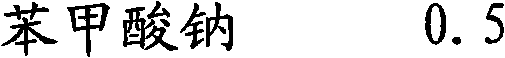

[0041]

[0042]

[0043] 2. Preparation method

[0044] Grind the glutinous rice into 100 meshes, ripen it with 60 parts of hot water at 80°C, disperse it evenly in the preservative, and mix it together with the liquid formula. Formula: liquid material formula = 5: 1 for mixing, stirring at room temperature. The adhesion force of the present invention is tested to be 0.75MPa.

Embodiment 3

[0046] 1. Formula (expressed in parts by weight)

[0047] Powder formula:

[0048] Cement 350 Yellow Mortar 800

[0050] Liquid formula

[0051]

[0052] 2. Preparation method

[0053] Grind the glutinous rice into 100 meshes, ripen it with 100 parts of hot water at 90°C, disperse it evenly in the preservative, and mix it with the liquid formula. Formula: liquid material formula = 5: 1 for mixing, stirring at room temperature. The adhesion force of the present invention is tested to be 0.82MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com