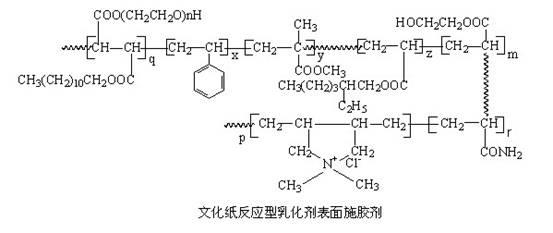

Cultural paper reactive emulsifier surface sizing agent and its preparation method

A reactive emulsifier and surface sizing agent technology, applied in the direction of water repellent addition, can solve the problems of poor stability, high emulsion viscosity, poor emulsification performance, etc., and achieve good binding force, low emulsion viscosity and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of cultural paper reactive emulsifier surface sizing agent, specifically comprising the following steps:

[0026] The first step, 2 grams of ammonium persulfate, 1 gram of sodium bisulfite and 20 grams of deionized water are made into an aqueous initiator solution with a mass ratio of 2: 1: 20,

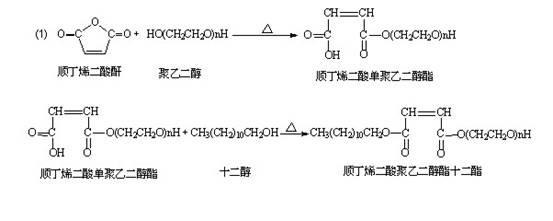

[0027] In the second step, 10 grams of polyethylene glycol-1000 and 0.98 grams of maleic anhydride were added to the first reactor and reacted at 80°C for 1.0 hour, then 1.86 grams of dodecyl alcohol was added and reacted at 85°C for 2.0 hours. Obtaining maleic acid polyethylene glycol ester dodecyl, the mass ratio of polyethylene glycol-1000, maleic anhydride and lauryl alcohol is 10: 0.98: 1.86,

[0028] In the third step, add 184 grams of deionized water to the second reactor, heat up to 50°C, add 9 grams of initiator aqueous solution and 30 grams of polyethylene glycol dodecyl maleate, 7 grams of The first mixed monomer made of styrene and 9 grams of m...

Embodiment 2

[0035] A preparation method of cultural paper reactive emulsifier surface sizing agent, specifically comprising the following steps:

[0036]The first step, 2 grams of ammonium persulfate, 1 gram of sodium bisulfite and 20 grams of deionized water are made into an aqueous initiator solution with a mass ratio of 2: 1: 20,

[0037] In the second step, 10 grams of polyethylene glycol-1000 and 0.98 grams of maleic anhydride were added to the first reactor and reacted at 81°C for 1.2 hours, then 1.86 grams of dodecyl alcohol was added and reacted at 86°C for 2.2 hours. Obtaining maleic acid polyethylene glycol ester dodecyl, the mass ratio of polyethylene glycol-1000, maleic anhydride and lauryl alcohol is 10: 0.98: 1.86,

[0038] In the third step, add 184 grams of deionized water to the second reactor, heat up to 51°C, add 9 grams of initiator aqueous solution and 30 grams of polyethylene glycol dodecyl maleate, 7 grams of The first mixed monomer made of styrene and 9 grams of m...

Embodiment 3

[0045] A preparation method of cultural paper reactive emulsifier surface sizing agent, specifically comprising the following steps:

[0046] The first step, 2 grams of ammonium persulfate, 1 gram of sodium bisulfite and 20 grams of deionized water are made into an aqueous initiator solution with a mass ratio of 2: 1: 20,

[0047] In the second step, 10 grams of polyethylene glycol-1000 and 0.98 grams of maleic anhydride were added to the first reactor and reacted at 82°C for 1.4 hours, then 1.86 grams of dodecyl alcohol was added and reacted at 87°C for 2.4 hours. Obtaining maleic acid polyethylene glycol ester dodecyl, the mass ratio of polyethylene glycol-1000, maleic anhydride and lauryl alcohol is 10: 0.98: 1.86,

[0048] In the third step, add 184 grams of deionized water to the second reactor, heat up to 52°C, add 9 grams of initiator aqueous solution and 30 grams of polyethylene glycol dodecyl maleate, 7 grams of The first mixed monomer made of styrene and 9 grams of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cobb value | aaaaa | aaaaa |

| Surface strength | aaaaa | aaaaa |

| Tensile index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com