Preparation method and application of cyclodextrin graft-immobilized cellulose acetate

A technology of cellulose acetate and cyclodextrin, applied in application, fiber treatment, plant fiber, etc., can solve the problem of high cost, achieve good safety, improve dyeing stability and dyeability, and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

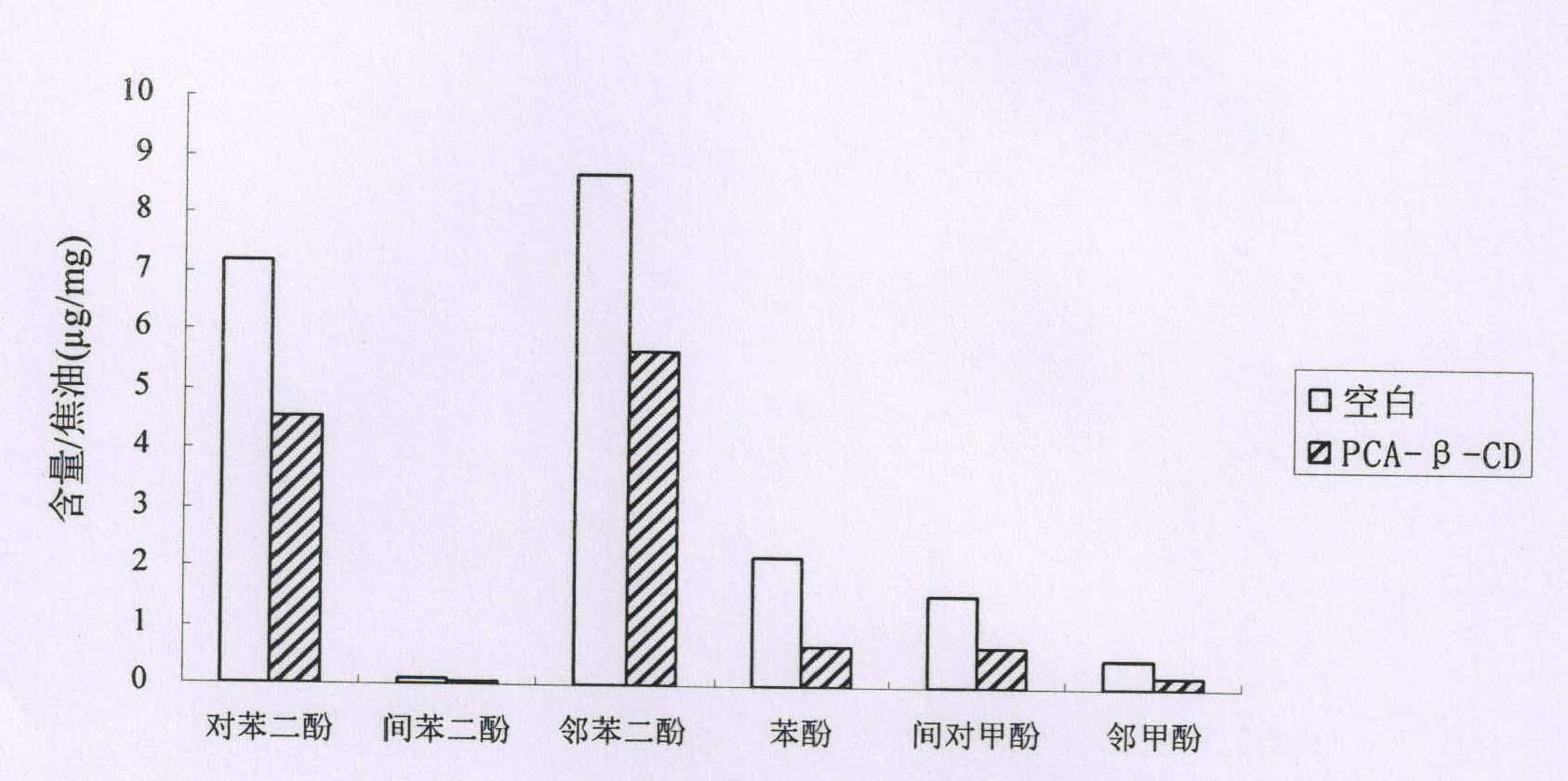

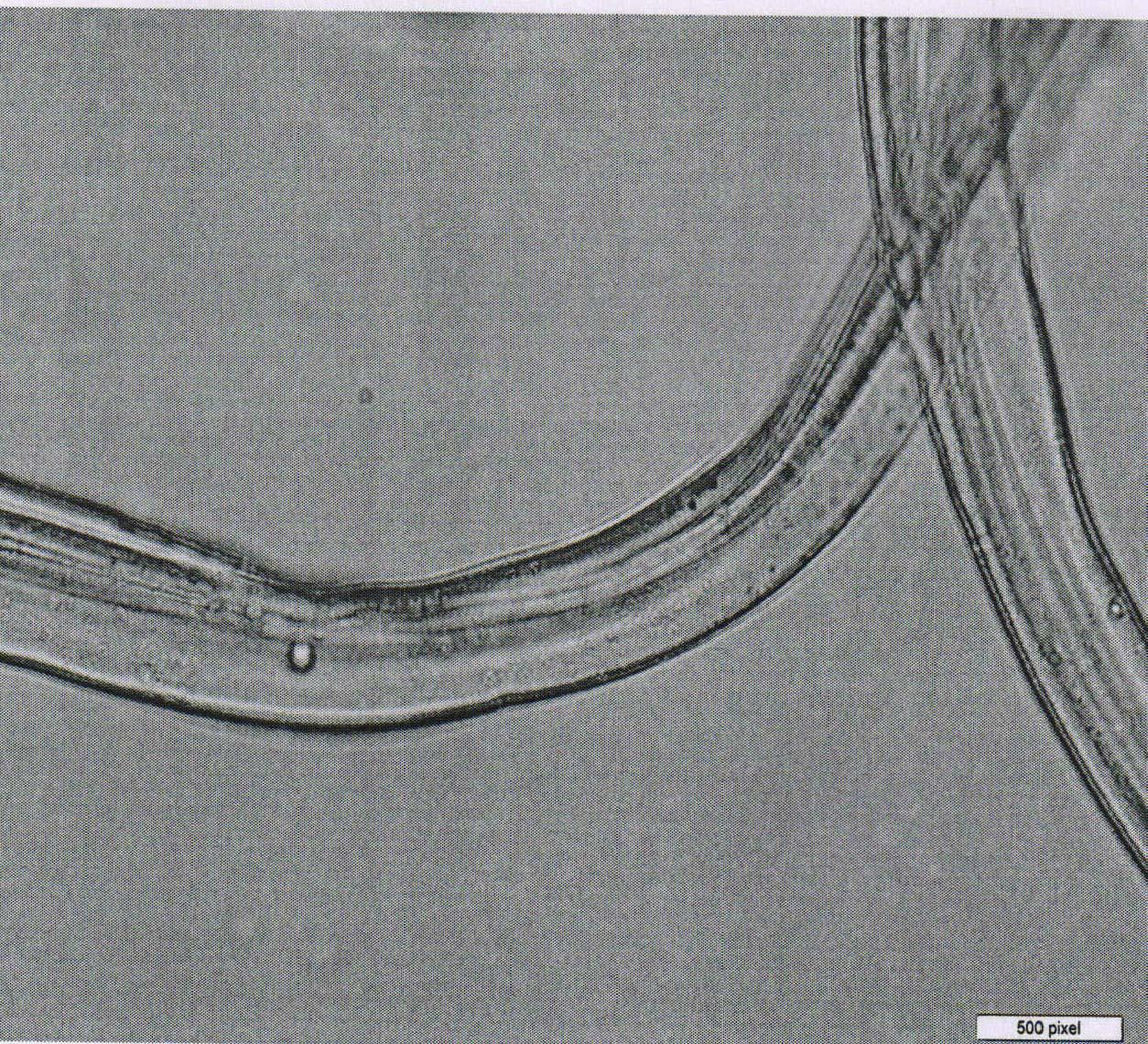

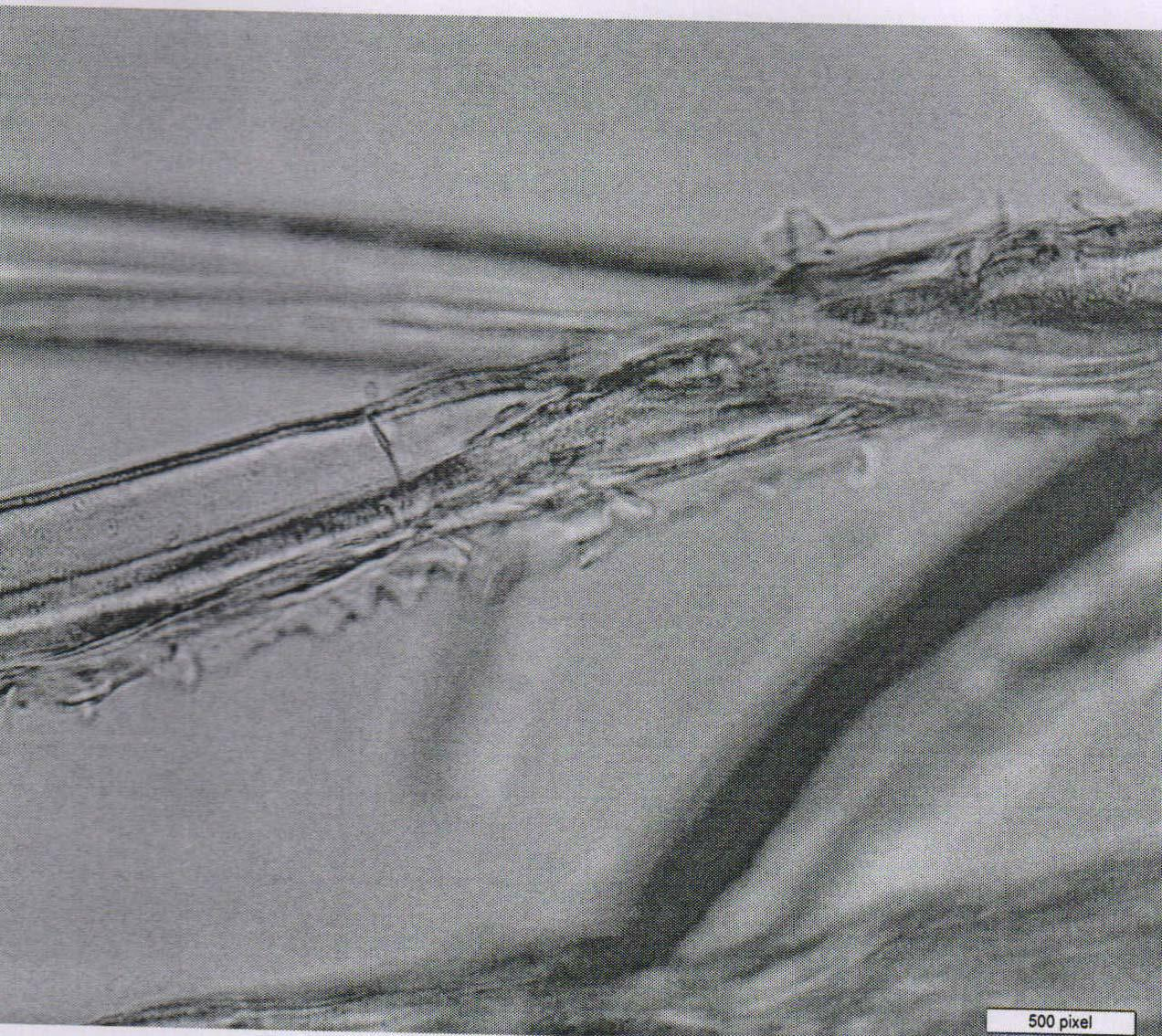

[0031] Weigh 100 g of β-cyclodextrin, 100 g of citric acid, 40 g of sodium dihydrogen phosphate, and dissolve 20 mL of polyethylene glycol in 1 liter of water to prepare β-cyclodextrin grafted cellulose acetate finishing solution. Take 10 g of cellulose diacetate, The two-dipping and two-rolling process is used to control the excess rate of 80%, then pre-baked at 90°C for 5 minutes, baked at 160°C for 2 minutes, soaked in water for 5 times, and dried naturally. The grafting rate of β-cyclodextrin in the product reaches 15%~25%.

example 2

[0033] Weigh 100g of β-cyclodextrin, 100g of citric acid, 40g of catalyst (disodium hydrogen phosphate) and 1 liter of water in a large beaker, fully stir the reaction at 120°C for 2 hours, take it out until the solution is cooled, and then place the mixture Reflux in ethanol solution for 6 hours to remove residual citric acid, catalyst and by-product impurities, finally dissolve the white solid product with a small amount of water, and precipitate it with acetone to obtain cyclodextrin and citric acid polymer. Weigh 100g of this polymer, dissolve 40g of sodium dihydrogen phosphate in 1 liter of water to prepare a finishing solution, take 10g of cellulose diacetate, adopt the process of double dipping and rolling, control the excess rate of 80%, and then pre-condition at 90°C Bake for 5 minutes, bake and react at 160°C for 2 minutes, soak in water for 5 times, and dry naturally. The grafting rate of β-cyclodextrin in the product reaches 20%-30%.

example 3

[0035]Weigh 200g of hydroxypropyl-β-cyclodextrin, 200g of citric acid, 100g of sodium hypophosphite, and dissolve 40mL of polyethylene glycol in 1 liter of water to prepare hydroxypropyl-β-cyclodextrin grafted cellulose acetate finishing solution , take 10g of cellulose diacetate, adopt the two-dipping and two-rolling process, control the excess rate of 90%, then pre-bake at 80°C for 7 minutes, bake at 170°C for 3 minutes, soak in water for 5 times, and naturally to dry. The grafting rate of hydroxypropyl-β-cyclodextrin in the product reaches 25%-40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com