Method and device for preparing electrospinning fiber bracket with three-dimensional structure

A technology of electrospun fibers and three-dimensional structures, which is applied in the direction of scaffolds, fiber processing, and complete sets of equipment for the production of artificial threads. value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

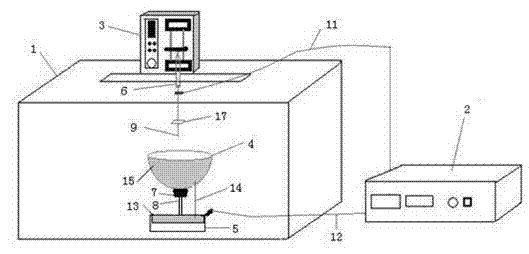

[0043] Example 1: A preparation device for electrospun fiber scaffold with three-dimensional structure

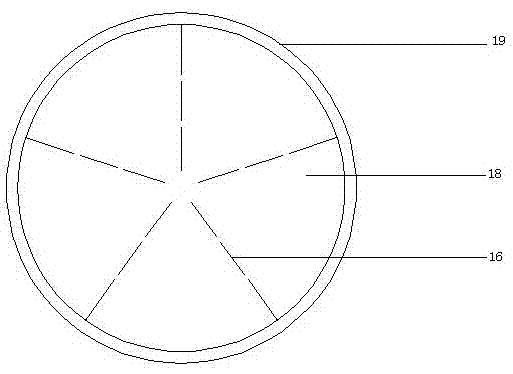

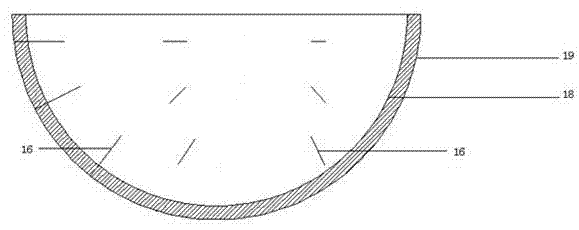

[0044] This embodiment provides a preparation device for an electrospun fiber scaffold with a three-dimensional structure such as figure 1 As shown, it consists of a spinning cabinet (1), a high-voltage power supply (2), a micro propulsion pump (3), a collector (4) and a rotating device (5); the top of the spinning cabinet (1) is equipped with a micro propulsion pump (3), the micro propulsion pump (3) is connected with a syringe (6); the interior of the spinning cabinet is provided with a collector (4) and a rotating device (5), and the collector (4) is an insulated bowl on the inner wall of the upper opening Type container, divide the bowl container into 5 equal parts with steel needle (16) along the central axis of the bowl container (see figure 2 ), the steel needles on the junction of any two adjacent parts are distributed at the same height, and three steel needles...

Embodiment 2

[0045] Example 2 : Using PLLA as a raw material to prepare three-dimensional nanofibrous tissue engineering scaffolds

[0046] 1. Preparation of spinning solution: Weigh 60 mg of PLLA (molecular weight = 200,000 Daltons) and dissolve in 1 ml (9:1, CH 2 Cl 2 / DMF, v / v) solvent, prepared 6% PLLA solution, sealed with parafilm, magnetically stirred for 3 hours, and set aside.

[0047] 2. Spinning process: adjust the parameters of the micro propulsion pump, the capacity is 0.2 ml, the propulsion speed is 0.5 ml / hour, and it is running. Turn on the rotating device and adjust the speed to make the rotation stable. Turn on the high-voltage power supply, adjust the voltage value to 14 kV, and start spinning.

[0048] 3. Separation of spinning fibers: Use a glass rod to gently remove the prepared three-dimensional fibers along the direction of the collector bowl wall. During this process, the force should be moderate to prevent the fiber material from sticking and destroying its t...

Embodiment 3

[0050] Example 3: Preparation of three-dimensional nanofibrous tissue engineering scaffolds using PCL as raw material

[0051] 1. Preparation of spinning solution: Weigh 60 mg of PCL (molecular weight = 80,000 Daltons) and dissolve in 1 ml (9:1, CH 2 Cl 2 / DMF, v / v) solvent to prepare a 6% PCL solution, seal the gap between the bottle cap and the bottle body of the strain bottle with a parafilm, stir magnetically for about 3 hours, and set aside.

[0052] 2. Spinning process: adjust the parameters of the micro propulsion pump, the capacity is 0.2 ml, the propulsion speed is 0.5 ml / hour, and it is running. Turn on the rotating device and adjust the speed to make the rotation stable. Turn on the high-voltage power supply, adjust the voltage value to 14 kV, and start spinning.

[0053] 3. Separation of spinning fibers: Use a glass rod to gently remove the prepared three-dimensional fibers along the direction of the collector bowl wall. During this process, the force should b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com