Seawater-based oil gas well fracturing fluid

A technology for oil and gas wells and fracturing fluids, which is applied in the field of fracturing fluids to achieve the effects of reducing damage, inhibiting clay expansion, and good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

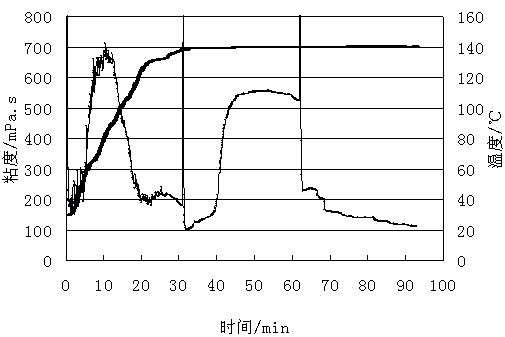

Image

Examples

preparation example Construction

[0026] Preparation of thickener

[0027] Put a 250mL four-necked flask equipped with a nitrogen device and a stirrer in a constant temperature water bath, add 100mL of distilled water, add 10-20 parts of acrylamide, stir to dissolve, add 3-10 parts of dimethyl diallyl chloride ammonium, 1-5 parts of vinylpyrrolidone, 1-4 parts of maleic acid, use 10% sodium hydroxide solution as a pH adjuster, adjust the pH of the system to between 7 and 8, pass nitrogen to remove oxygen, add 5% ammonium persulfate solution was used as the initiator. Continue to blow nitrogen, raise the temperature of the water bath to 40-45°C, and continue the reaction in the constant temperature water bath for 10-24 hours to obtain a viscous liquid, which is precipitated with absolute ethanol, washed three times, and then vacuum-dried at 60°C to constant weight.

Embodiment 1

[0029] Take 100 parts of 10% salt water, add 0.6 parts of thickener under stirring, add 0.3 parts of drainage aid (non-ionic surfactant OP-10), 3 parts of organometallic composite cross-linking agent, capsule form 0.03 part of ammonium persulfate was added and mixed to prepare the fracturing fluid of the present invention.

[0030] The organometallic composite crosslinking agent is prepared by zirconium oxychloride, tartaric acid and water according to the mass ratio of 1:0.5:3, and the pH value is adjusted to 6.5 with triethanolamine.

Embodiment 2

[0031] Example 2: Take the formation water from the Ordos Basin, add 1.2 parts of the thickener to 100 parts of the formation water after removing oil and suspended solids under stirring, wherein the salinity of the formation water is 7.8×10 4 mg / L, after dissolving, add 0.2 part of drainage aid (polyoxyethylene perfluorooctyl ether-14), 8 parts of organometallic composite crosslinking agent, and 0.1 part of ammonium persulfate in the form of capsule, add and mix to prepare Obtain the fracturing fluid of the present invention.

[0032] Organometallic composite cross-linking agent: mix 2 parts of ferric chloride and 1 part of aluminum chloride, add 1 part of tartaric acid, 0.5 parts of sodium gluconate, 6 parts of water, and adjust the pH value to 7 with triethanolamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com