Sapphire crucible for growing garnet type single crystal

A garnet type and sapphire technology, which is applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems that the deviation of the melt composition from the stoichiometry cannot be corrected in time, the observation is inconvenient, and the acceleration is accelerated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the specific drawings and embodiments.

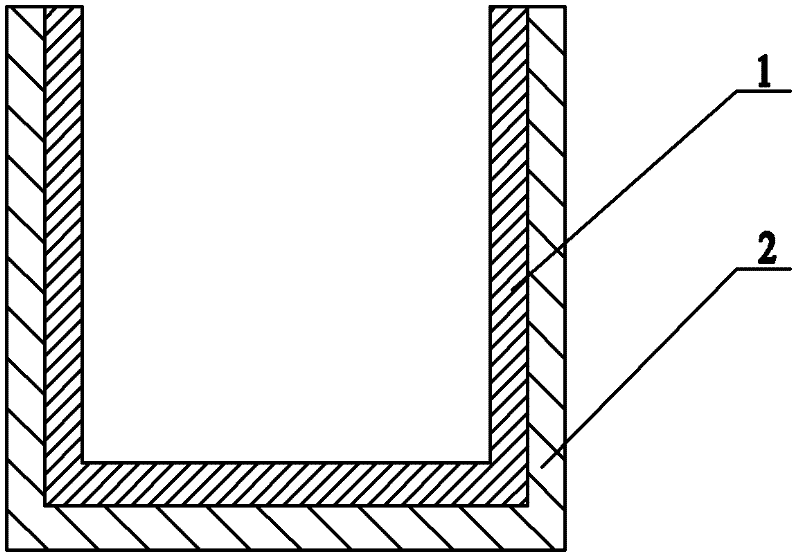

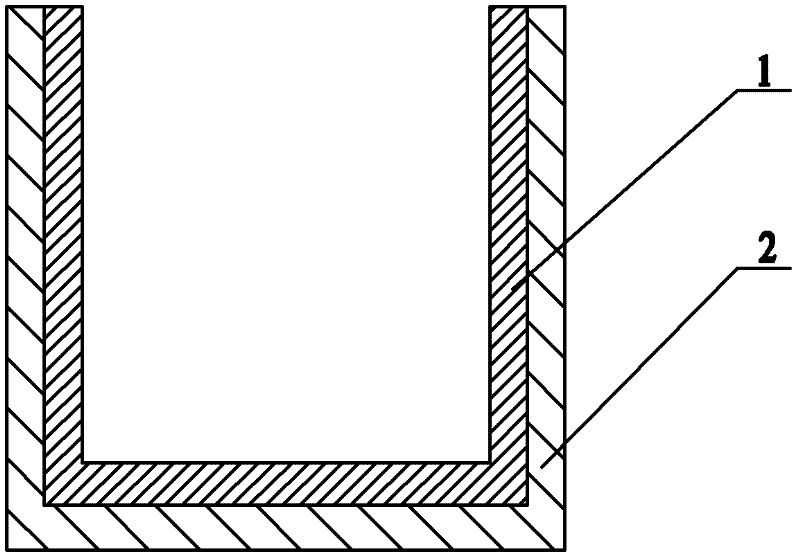

[0015] As shown in the figure, a sapphire crucible for growing garnet-type single crystal includes an inner crucible 1 and an outer crucible 2, the inner crucible 1 is arranged outside the outer crucible 2, the inner crucible 1 is flush with the top surface of the outer crucible 2, and the inner crucible 1 is flush with the outer crucible 2. The cross-sectional shape of the crucible 1 and the outer crucible 2 match, and the inner crucible 1 is made of sapphire.

[0016] The outer crucible 2 is made of tungsten or molybdenum.

[0017] The inner diameter of the inner crucible 1 is 60-70 mm, the wall thickness of the inner crucible 1 is 3-6 mm, and the height of the inner crucible 1 is 40-45 mm.

[0018] The inner diameter of the outer crucible 2 is 66-82 mm, the wall thickness of the outer crucible 2 is 5-8 mm, and the height of the outer crucible 2 is 40-50 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com