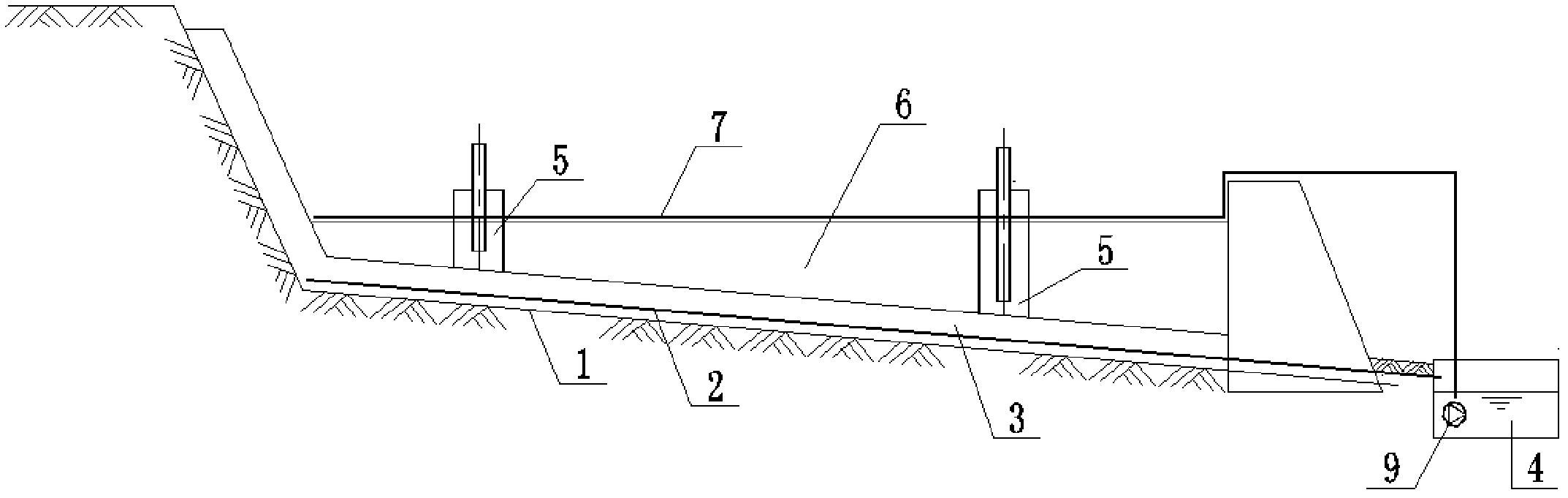

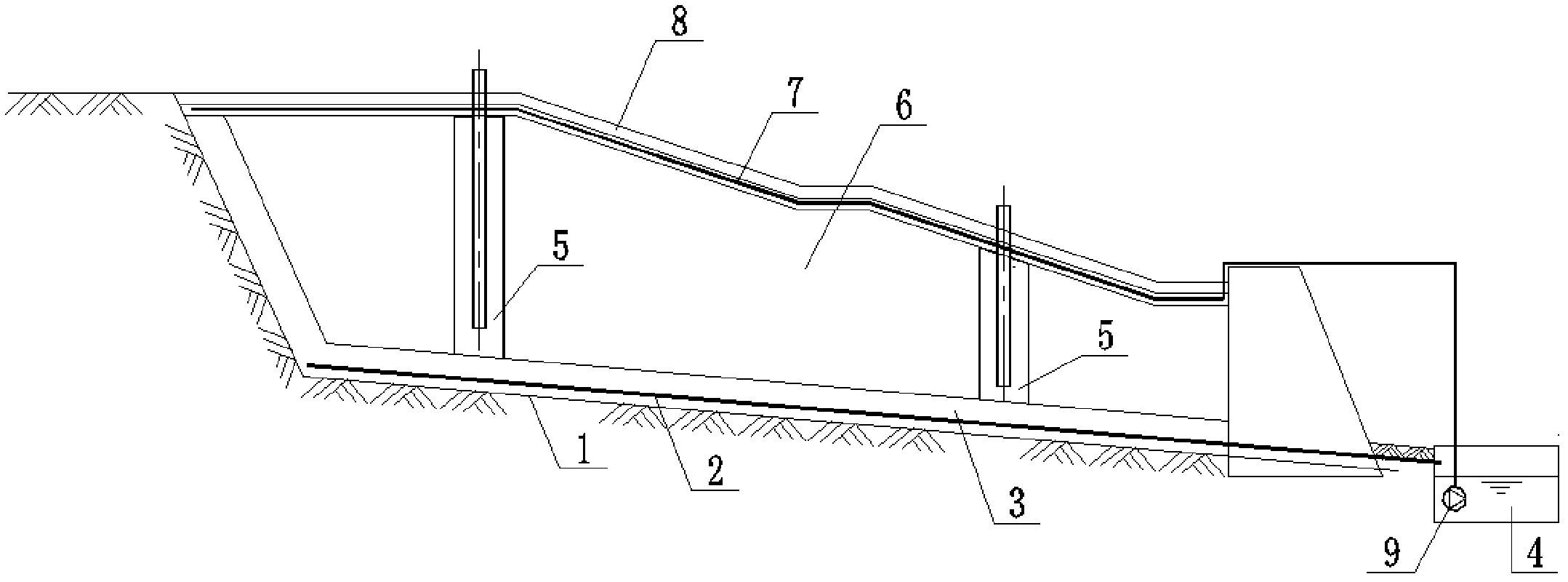

Landfill method for accelerating percolate degradation in landfill site

A landfill and leachate technology, which is applied in filling, sustainable biological treatment, aerobic process treatment, etc., can solve the problem of high investment and operating costs, high investment and operating costs in small towns, landfill It can reduce the amount of odor generated, improve the surrounding environment, reduce the amount of generation and treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

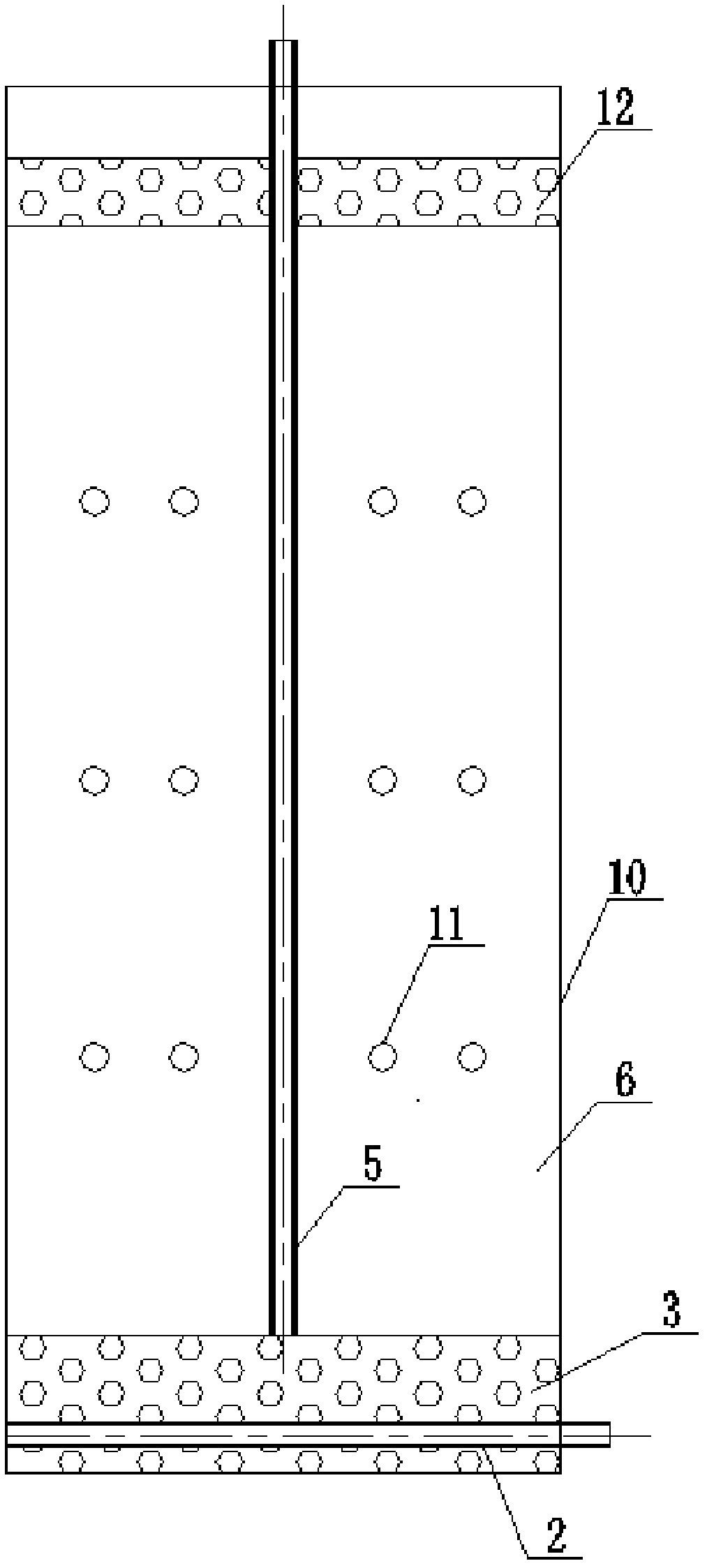

Method used

Image

Examples

Embodiment

[0061] In order to further verify the effect of the present invention, the applicant adopted the method of the present invention to do a test verification on the spot of a certain garbage landfill in Sichuan.

[0062] A landfill in Sichuan covers a total area of 42 mu, with a designed storage capacity of 105,000 cubic meters, a designed service life of 9 years, and a designed average treatment capacity of 24.2 tons per day. The climate of the landfill site belongs to the plateau continental monsoon climate, and the climate is dry. The annual average rainfall is 786.4mm, the annual average evaporation is 1536.4mm, and the average wind speed is 1.2m / s. Using the leachate back-spray quasi-aerobic landfill process of the present invention, the leachate is back-sprayed to the surface of the garbage body during operation, and the hydraulic load of the back-spray is 4.8-6.4L / (m 2 d) is 80% of the local water surface evaporation. After more than half a year of commissioning and oper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com