Packaging structure of light source of high power LED

A technology of LED light source and packaging structure, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of the volume and limited number of thermal conductive columns, and limit the thermal conductivity of the packaging structure, so as to prevent heat accumulation, improve the thermal conductivity, and improve the thermal conductivity. The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

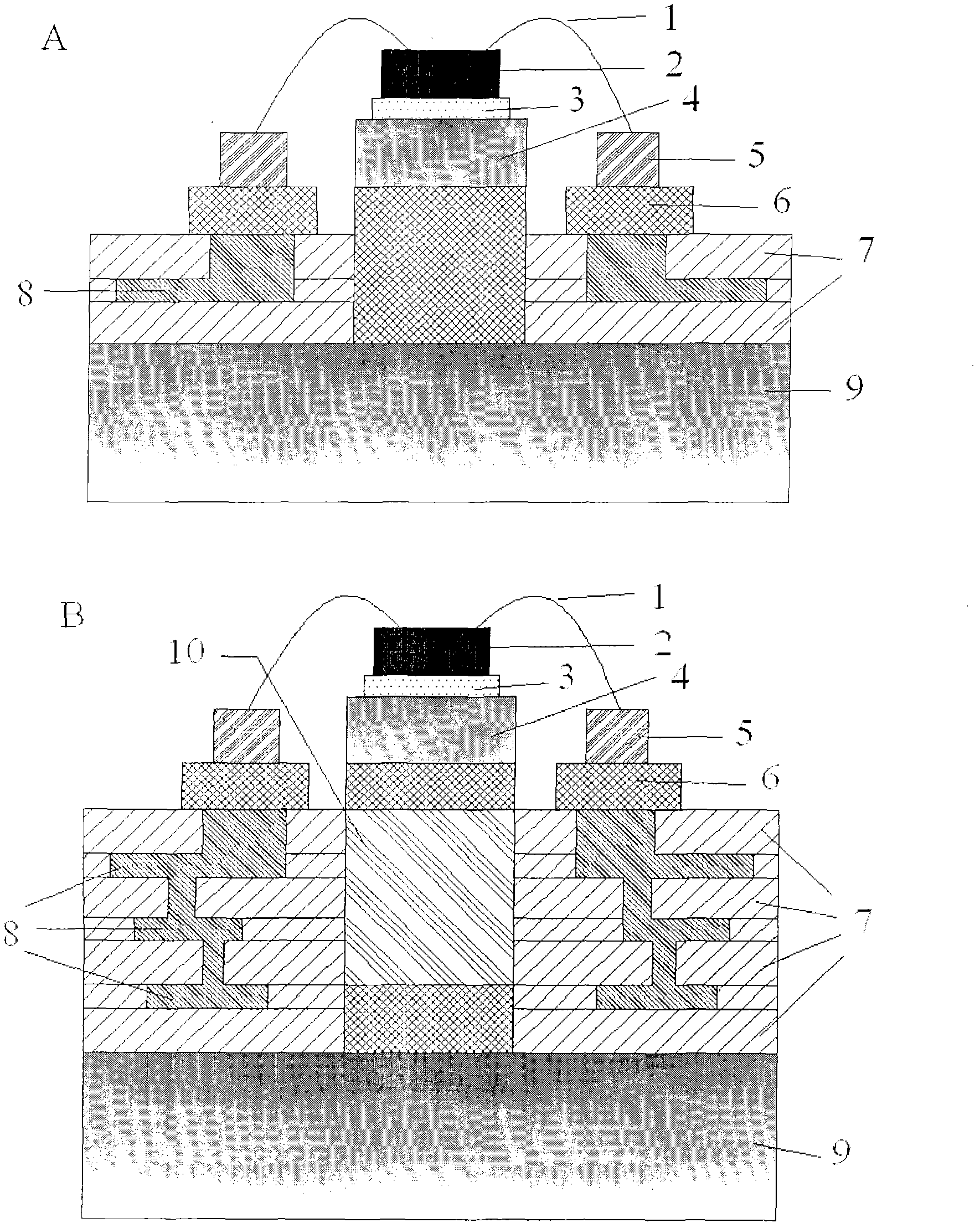

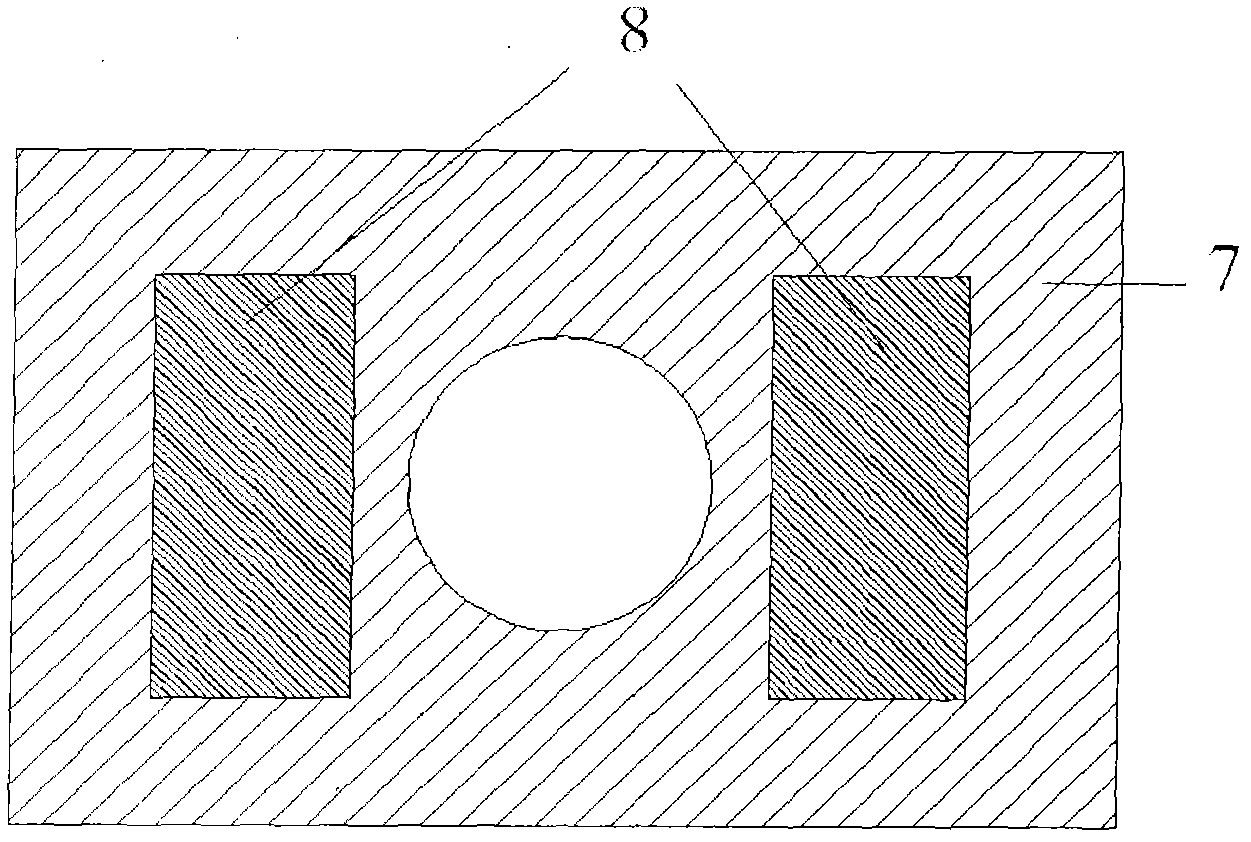

[0025] Such as figure 1 As shown in A, to design a single-layer simple circuit, a total of two layers of LTCC green ceramic sheets (7) are required. Firstly, silver paste of conductive paste (8) is printed on the first layer of ceramic sheet (7) to form a circuit required for design, and a hole is punched in the middle of the ceramic sheet (7) to cut out a heat conduction cavity. Then, superimpose the second layer of LTCC green ceramic sheet (7) on the conductive layer, exposing the electrode position (as attached figure 2 As shown), the second layer of green ceramic sheet is also cut out with the same heat conduction cavity shape as the first layer of ceramic sheet, and co-fired to combine to form an LTCC substrate. The LTCC substrate is closely connected with the metal heat dissipation base (9) and the aluminum alloy substrate with the LED chip through solder (6). At the same time, the electrodes (5) of the LED chip particles are welded on the LTCC substrate through the s...

Embodiment 2

[0027] To design a multi-layer circuit, the number of LTCC layers required increases, and the circuit and heat conduction cavity manufacturing process are as shown in the first embodiment. The axial size of the heat conduction chamber increases, so it is not suitable to use solder to connect the chip particles and the metal heat dissipation base. At this time, a metal heat conductor with a thermal expansion coefficient matching the LTCC material is selected (10) Cu-Mo-Cu alloy is co-fired with the LTCC substrate, and preheated Leave a certain welding position, such as figure 1 As shown in B, the fired LTCC substrate is then welded to the metal heat dissipation base and chip particles.

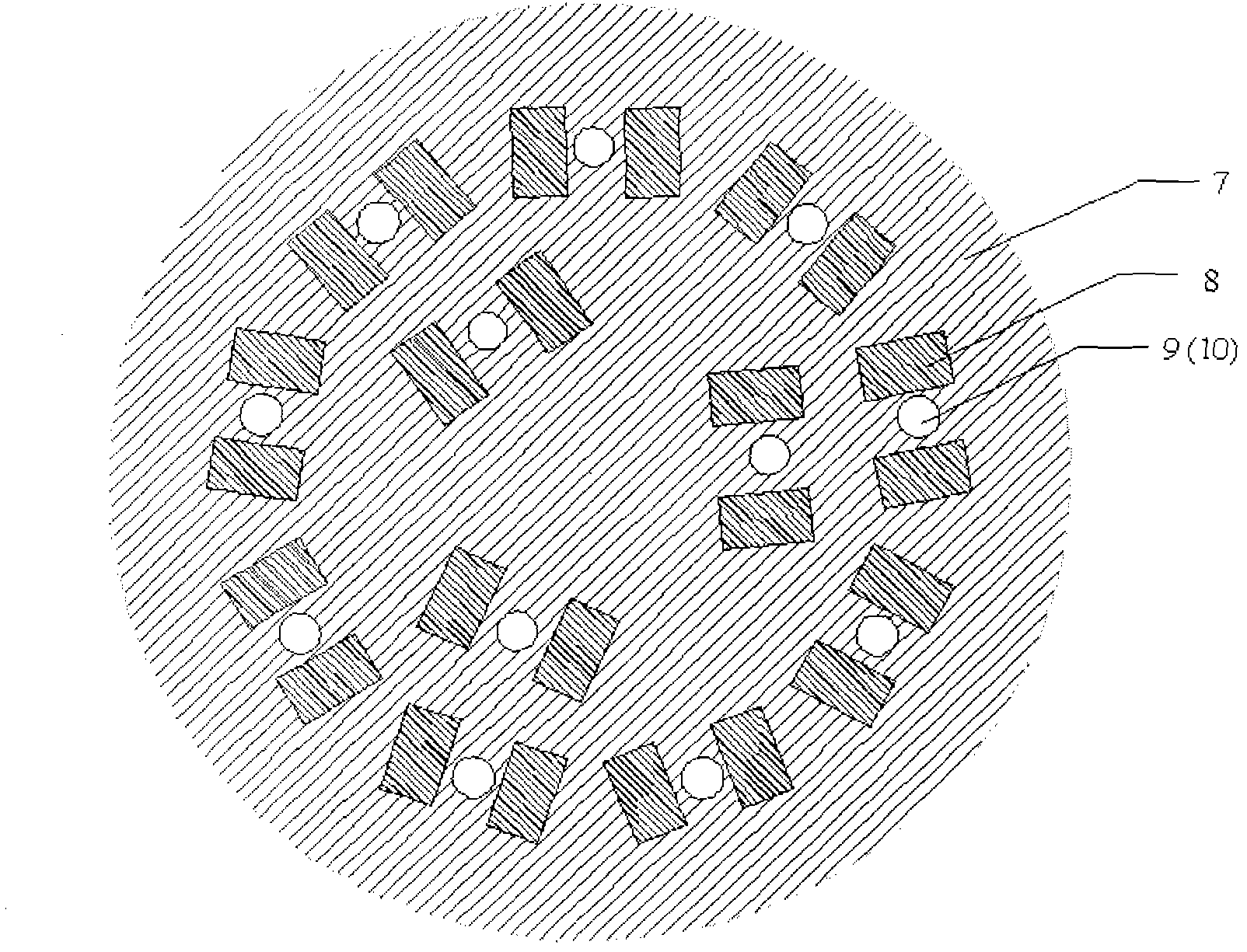

[0028] In this embodiment, the LED array can be designed into different numbers of circular arrangements, rhombus staggered arrangements, etc. according to needs, without limitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com