Solar high-temperature phase change thermal storage device

A high-temperature phase change and heat storage device technology, which is applied in solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problem of low thermal conductivity of inorganic salt high-temperature phase change materials, affecting the heating and heat release of phase change materials, and affecting the utilization of thermal energy. Efficiency and other issues, to achieve high temperature stability and repeatability, long service life, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

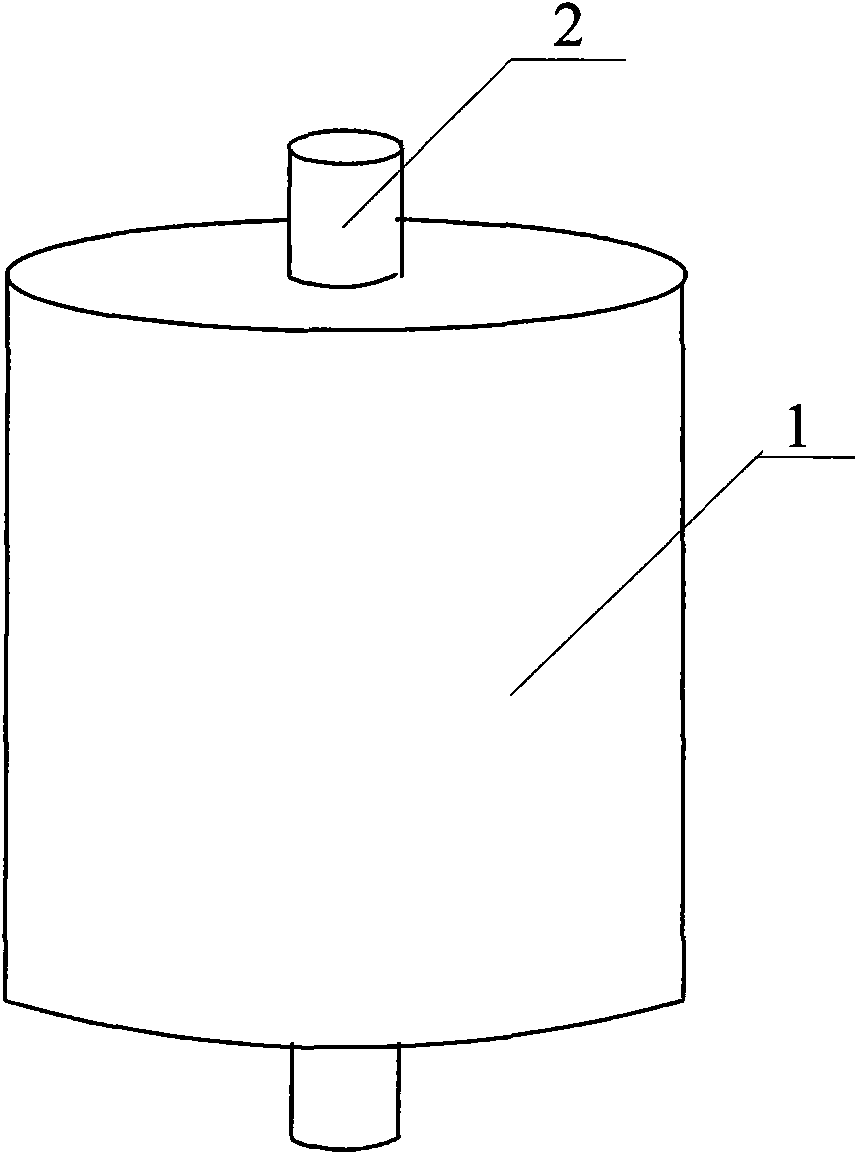

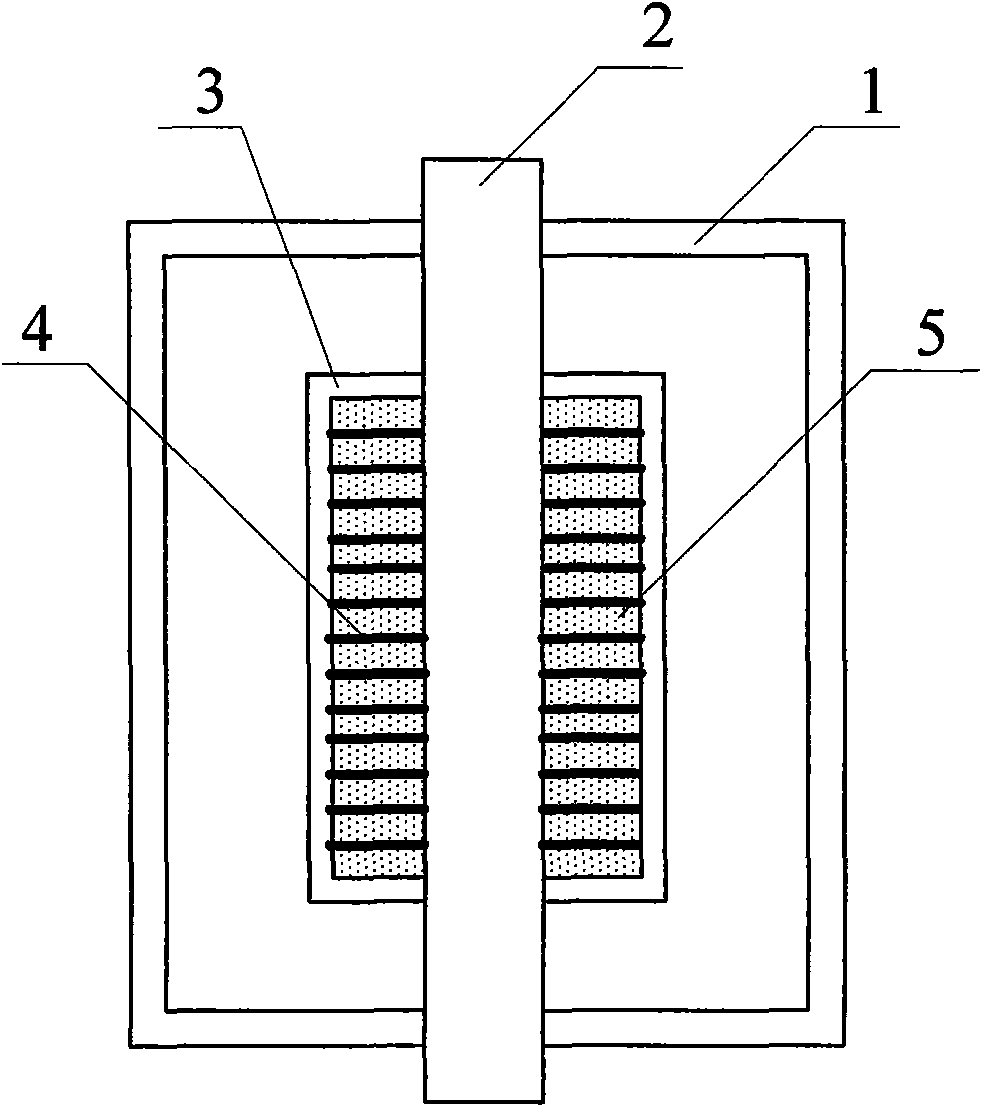

[0027] Small solar high temperature storage and heat release unit

[0028] 1) Specific specifications of each part:

[0029] (1) Metal shell, 500×600mm (outer diameter×height);

[0030] (2) Stainless steel conduit, outer diameter 100mm;

[0031] (3) Insulation material, thickness 100mm;

[0032] (4) Corundum container, thickness 5mm, outer diameter 296mm, height 398mm;

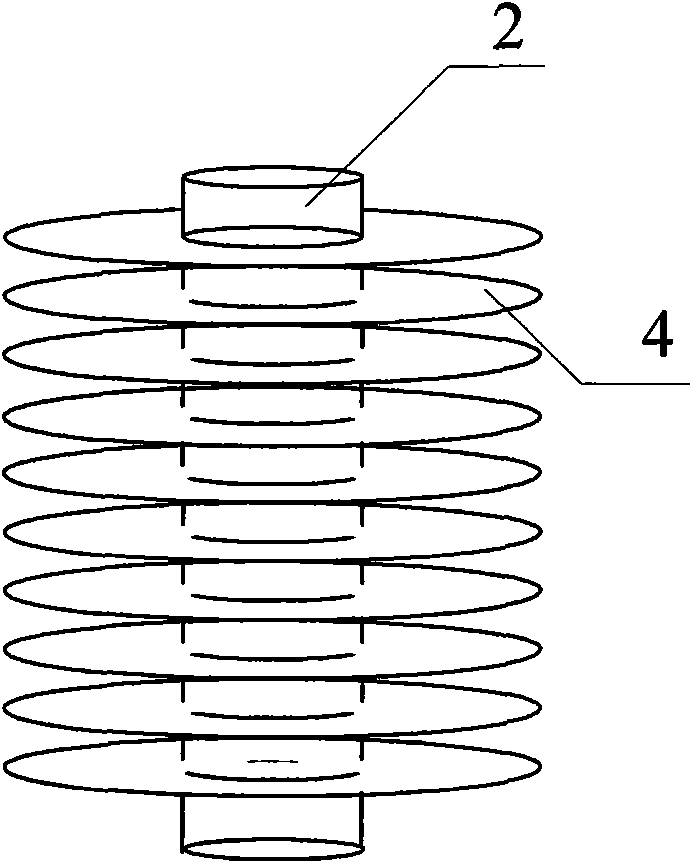

[0033] (5) Stainless steel fins with a thickness of 2 mm, a radius of 91 mm, and a fin spacing of 5 mm.

[0034] 2) Experimental process of design of stainless steel tubes and fins

[0035] The diameter of the stainless steel pipe, the thickness and spacing of the stainless steel fins directly affect the efficiency of heat conduction and the heat storage efficiency of the heat storage unit, and are key factors in the design process of the heat storage unit. To this end, the following experimental procedures were carried out:

[0036] (1) Determine the diameter of the stainless steel conduit

[0037] Sta...

Embodiment 2

[0042] Medium-sized solar high temperature storage and heat release unit

[0043] 1) Specific specifications of each part:

[0044] (1) Metal shell, 860×1000mm (outer diameter×height);

[0045] (2) Stainless steel conduit, outer diameter 120mm;

[0046] (3) Insulation material, thickness 100mm;

[0047] (4) Corundum container, thickness 30mm, outer diameter 600mm, height 720mm;

[0048] (5) Stainless steel fins with a thickness of 2 mm, a radius of 200 mm, and a fin spacing of 50 mm.

[0049] 2) Phase change material: graphite / inorganic salt high-temperature phase change heat storage composite material with a melting point of 600°C and a density of 2g / cm 3 , the phase change enthalpy is 500J / g. The total mass of the phase change material in this example is 2×10 5 kg, and the total phase change heat storage is 100MJ.

Embodiment 3

[0051] Large-scale solar high temperature storage and heat release unit

[0052] 1) Specific specifications of each part:

[0053] (1) Metal shell, 2000×5000mm (outer diameter×height);

[0054] (2) Stainless steel conduit, outer diameter 400mm;

[0055] (3) Insulation material, thickness 100mm;

[0056] (4) Corundum container, thickness 50mm, outer diameter 1780mm, height 4780mm;

[0057] (5) Stainless steel fins with a thickness of 30mm, a radius of 640mm, and a fin spacing of 30mm.

[0058] 2) Phase change material: graphite / inorganic salt high-temperature phase change heat storage composite material is used, with a melting point of 600°C, a density of 1.8g / cm3, and a phase change enthalpy of 500J / g. The total mass of the phase change material in this example is 8.6×10 3 kg, the total phase change heat storage is 4.3×10 3 MJ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com