Advanced treatment method and device for nonbiodegradable organic wastewater by utilizing O3 catalytic oxidation

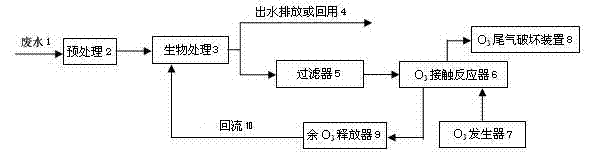

A refractory biodegradable and catalytic oxidation technology, applied in oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve high initial investment and operation costs, difficult operation and maintenance management, and long process flow and other issues, to achieve the effect of reducing infrastructure and operating costs, reducing the difficulty of production management, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

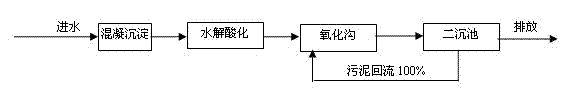

[0044] A centralized sewage treatment plant in a textile printing and dyeing and tanning industrial park, with a treatment capacity of 5,000 tons per day, currently adopts coagulation sedimentation-hydrolysis acidification-oxidation ditch process, see image 3 shown. The hydrolytic acidification tank is HRT 9.0 h, the oxidation ditch is Carrousel oxidation ditch, and the sludge load is 0.10kgBOD 5 / (kg MLSS.d) is adopted, the sludge age is 16 days, the secondary settling tank adopts a radial flow secondary settling tank with central water inlet, the HRT of the secondary settling tank is 4.0h, and the sludge return ratio is 100%.

[0045] The system feed water COD 500-700 mg / L, ammonia nitrogen 35-50 mg / L, total nitrogen 40-65 mg / L, total phosphorus 2.0-5.0 mg / L, chromaticity 80-200 times. through figure 2 After process treatment, the effluent COD is 70-150 mg / L, ammonia nitrogen ≤8 mg / L, TP ≤1.5mg / L, chroma 40-120 mg / L, and the effluent quality is difficult to meet the "Pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com