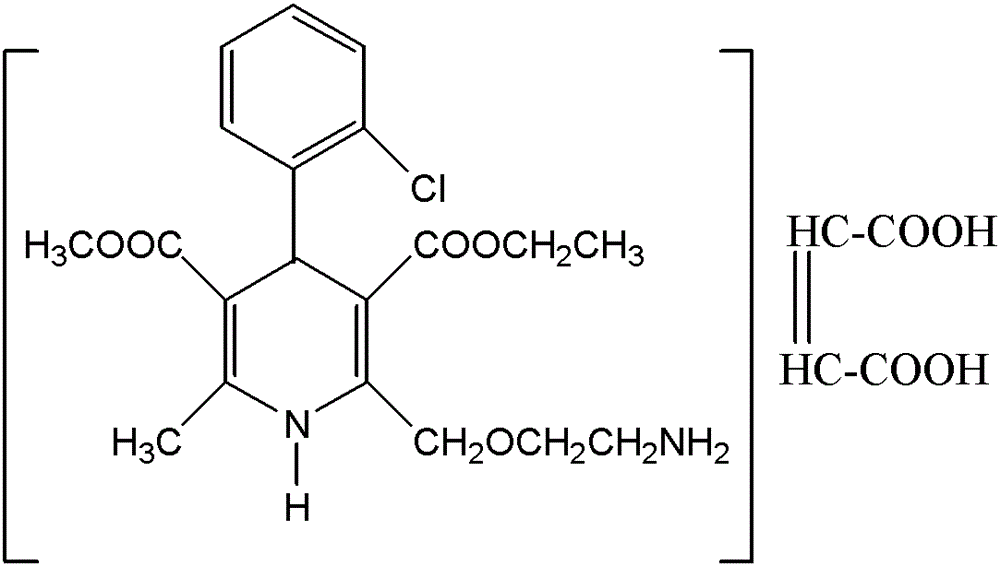

A kind of preparation method of amlodipine maleate

A kind of technology of amlodipine maleate and amlodipine, applied in the field of preparation of amlodipine maleate, can solve problems such as long drying time, poor finished product crystal, difficult filtration and the like, achieve easy vacuum filtration, reduce dosage, The effect of shortening the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, the preparation of amlodipine maleate salt

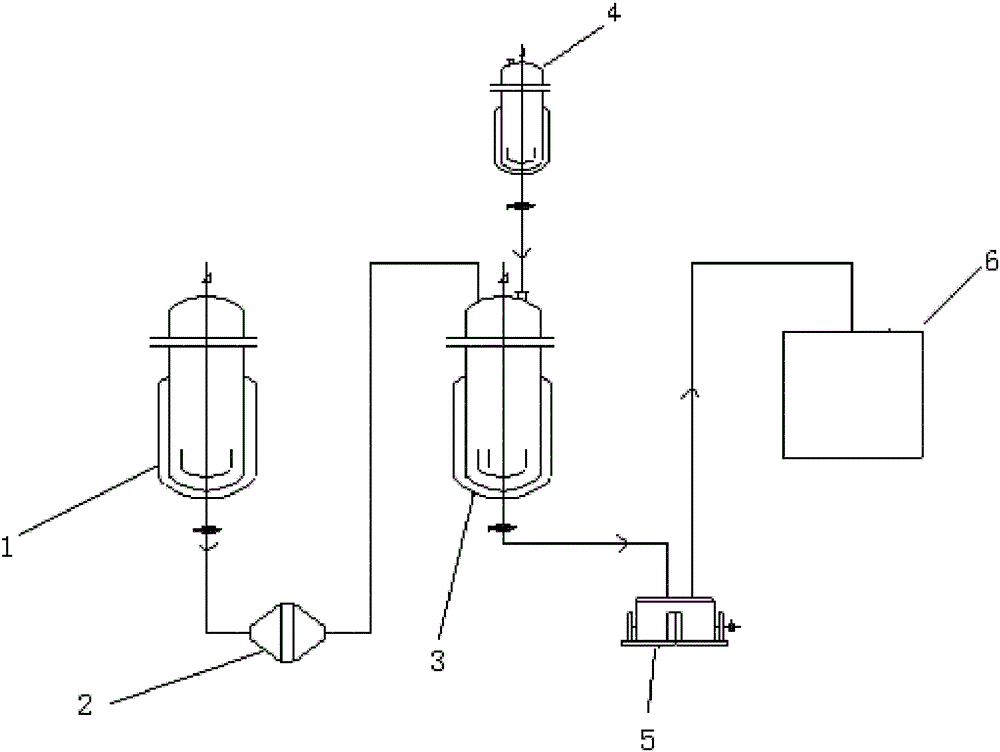

[0019] Step 1, preparation of maleic acid solution and amlodipine solution: at 35-40°C, in glass-lined tank 1, dissolve 3.0 kg of solid maleic acid into 7 liters of anhydrous methanol, and the solution Filter under pressure filter 2 into clean glass-lined tank 4; under 20-25°C, in glass-lined tank 1, dissolve 10 kg of solid amlodipine in 15 liters of anhydrous methanol . The solution is passed through a pressure filter 2 into a clean glass-lined tank 3 by means of pressure filtration.

[0020] Step 2, the generation of amlodipine maleate salt: the maleic acid solution prepared in the previous step is slowly added dropwise into the glass-lined tank 3 through the glass-lined tank 4, and the temperature in the reactor is kept at 20-25 ° C. After the addition was complete, the mixture was kept at 20-30°C and stirred for 3 hours, then slowly cooled to 3°C, and the mixture was allowed to stand for 12 hours.

[0021...

Embodiment 2

[0023] Embodiment two, the preparation of amlodipine maleate salt

[0024] Step 1, preparation of maleic acid solution and amlodipine solution: at 35-40°C, in glass-lined tank 1, dissolve 3.5 kg of solid maleic acid into 7 liters of anhydrous methanol, and the solution Filter into a clean glass-lined tank 4 by pressure filter 2 in the manner of pressure filtration; 15 kilograms of solid amlodipine are all dissolved in 15 liters of anhydrous methanol in the glass-lined tank 1 under the condition of 20-25 ° C, and the solution Filter 2 into a clean glass-lined tank 3 through a press filter by means of pressure filtration.

[0025] Step 2, the generation of amlodipine maleate salt: the maleic acid solution prepared in the previous step is slowly added dropwise into the glass-lined tank 3 through the glass-lined tank 4, and the temperature in the reactor is kept at 20-25 ° C. After the addition was complete, the mixture was kept and stirred at 25-40°C for 2 hours, then slowly coo...

Embodiment 3

[0028] Embodiment three, the preparation of amlodipine maleate salt

[0029] Step 1, preparation of maleic acid solution and amlodipine solution: 1.4 kg of solid maleic acid is completely dissolved in 7 liters of anhydrous methanol in glass-lined tank 1 at 35-40 ° C, and the solution is added to The mode of pressure filtration is filtered into clean glass-lined jar 4 by press filter 2; 5 kilograms of solid amlodipine are all dissolved in 15 liters of anhydrous methanol in glass-lined jar 1 under the condition of 20-25 ℃, and solution is added with Press Filtration Method Filter through a press filter 2 into a clean glass-lined tank 3 .

[0030] Step 2, the generation of amlodipine maleate salt: the maleic acid solution prepared in the previous step is slowly added dropwise into the glass-lined tank 3 through the glass-lined tank 4, and the temperature in the reactor is kept at 20-25 ° C. After the addition was complete, the mixture was kept and stirred at 25-50°C for 5 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com