Enrichment culture method of salt-tolerant nitrifying bacterium communities

A technology of enrichment culture and nitrifying bacteria, applied in the field of microorganisms, can solve the problems of unsuitable treatment of high-salt ammonia nitrogen wastewater, achieve good economic and environmental benefits, easy to cultivate, and reduce the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

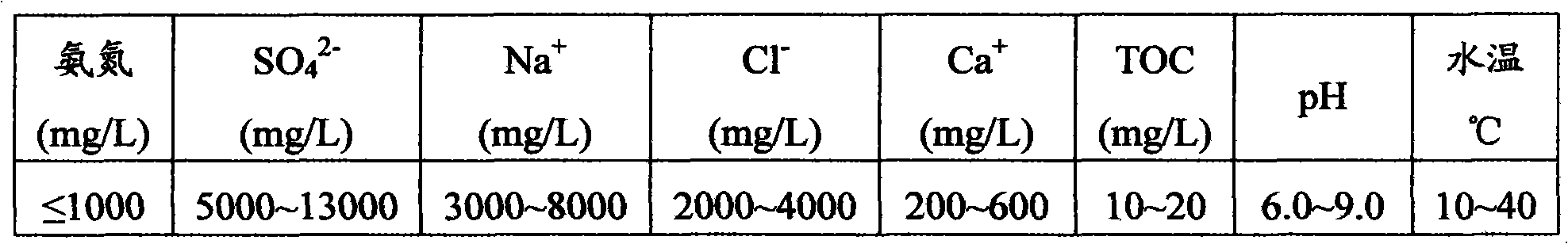

Image

Examples

Embodiment 1

[0048] a. Enrichment culture of nitrifying bacteria: activated sludge is taken from a nitrification test device of a sewage treatment plant, and the activated sludge is inoculated into the SBR reactor at a concentration of 2g / L, and enriched culture medium is added, and the composition of the enriched culture medium is : NH 4 + -N(NH 4 HCO 3 )200~600mg / L; Fe 2+ (FeSO 4 ·7H 2 O) 10mg / L; Mg 2+ (MgSO 4 ·7H 2 O) 15mg / L; P (KH 2 PO 4 ) 60mg / L; Add sodium bicarbonate according to the carbon-nitrogen ratio (0.5-20):1. During the enrichment and cultivation of nitrifying bacteria, one operating cycle is 24 hours, of which: water intake for 15 minutes, aeration for 20 hours, sedimentation for 2 hours, drainage for 1 hour, and the remaining time is the idle period; the dissolved oxygen value in the reactor is controlled at 2.5-4.5mg / L, the pH is controlled between 6.0 and 8.5, and the temperature is controlled between 15 and 37°C. In the process of enriching and cultivating ...

Embodiment 2

[0051] a. Enrichment culture of nitrifying bacteria: the activated sludge is taken from the aeration tank of the sewage treatment workshop of a chemical plant, and the activated sludge is inoculated into the SBR reactor at a concentration of 2.5g / L, and the enrichment culture solution is added for enrichment culture The liquid composition is: NH 4 + -N(NH 4 HCO 3 )100~700mg / L; Fe 2+ (FeSO 4 ·7H 2 O) 12mg / L; Mg 2+ (MgSO 4 ·7H 2 O) 20mg / L; P (KH 2 PO 4 )65mg / L; Add sodium bicarbonate according to the carbon-nitrogen ratio (0.5-20):1. During the enrichment and cultivation of nitrifying bacteria, an operation cycle is 24 hours, in which: 15 minutes of water inflow, 20 hours of aeration, 2 hours of sedimentation, 1 hour of drainage, and the rest of the idle period; the dissolved oxygen value in the reactor is controlled at 1.5-5.5 mg / L, the pH is controlled between 6.5 and 8.8, and the temperature is controlled between 15 and 37°C. In the process of enriching and culti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com