Colored photosensitive composition, color filter manufacture method, color filter and liquid crystal display device

A technology of photosensitive composition and coloring layer, which is applied in the photoplate making process of patterned surface, photosensitive material used in optomechanical equipment, optics, etc., and can solve the problem of narrow development latitude, unstable performance over time, particle size, etc. Small and other problems, to achieve the effect of wide development latitude, excellent stability over time, and high contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] -Preparation of pigment dispersion composition-

[0093] The preparation method of the pigment dispersion composition of the present invention is not particularly limited, for example, by using a vertical or desktop sand mill, nail mill, slit mill (slit mill), ultrasonic disperser, etc., with a particle size of 0.01 ~1 mm beads made of glass, zirconia, etc. are obtained by microdispersing pigments, pigment dispersants and solvents.

[0094] Two-roll mill, three-roll mill, ball mill, trommel, disperser, kneader, two-way kneader, homogenizer, mixer, single-screw or twin-screw extruder can also be used before bead dispersion. Kneading and dispersing treatment is carried out while applying strong shear force.

[0095] In addition, details about kneading and dispersion are described in "Paint Flow and Pigment Dispersion" by T.C. Patton (John Wiley and Sons, 1964) and the like.

[0096] -Pigment concentration-

[0097]The content of the pigment in the pigment dispersion co...

Embodiment 1

[0356]

[0357] The colored photosensitive composition of Example 1 was prepared by stirring and mixing the components shown in the following composition 1.

[0358] (composition 1)

[0359] · 33.0 parts of pigment dispersion composition containing PG58

[0360] ·15.2 parts of pigment dispersion composition containing PY150

[0361] ·Solvent (PGMEA) 20.1 parts

[0362] 24.6 parts of solvent (3-ethoxyethyl propionate)

[0363] ・Binder resin (allyl methacrylate-methacrylic acid (=copolymerization molar ratio: 8:2) copolymer, weight average molecular weight: 30000) 0.78 parts

[0364] ・Polymerizable monomer: ARONIX M-520 (manufactured by Toagosei Co., Ltd.) 4.43 parts

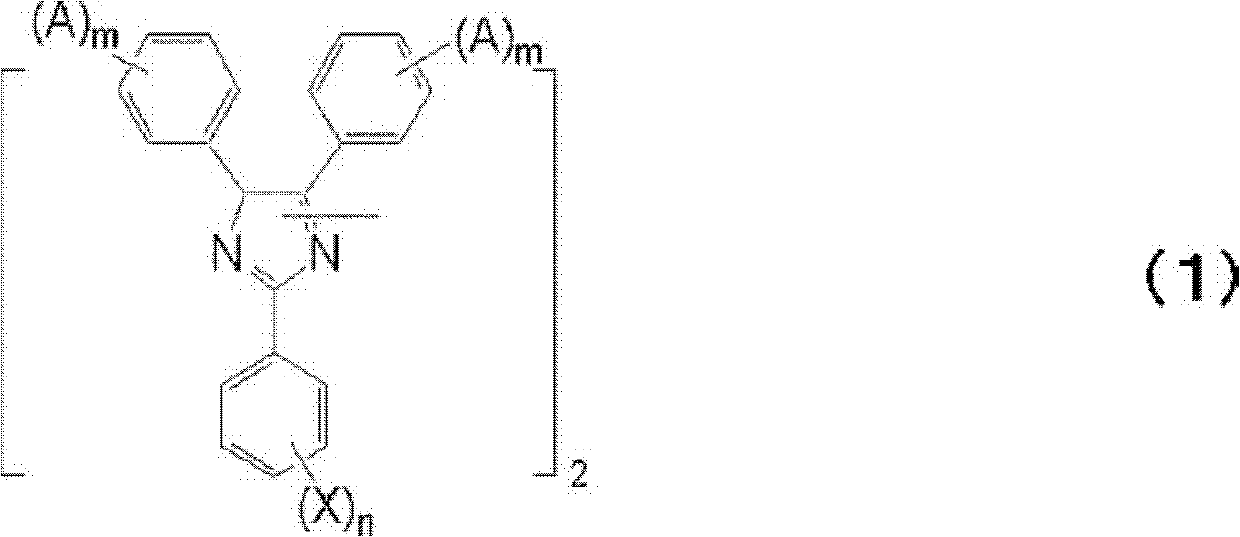

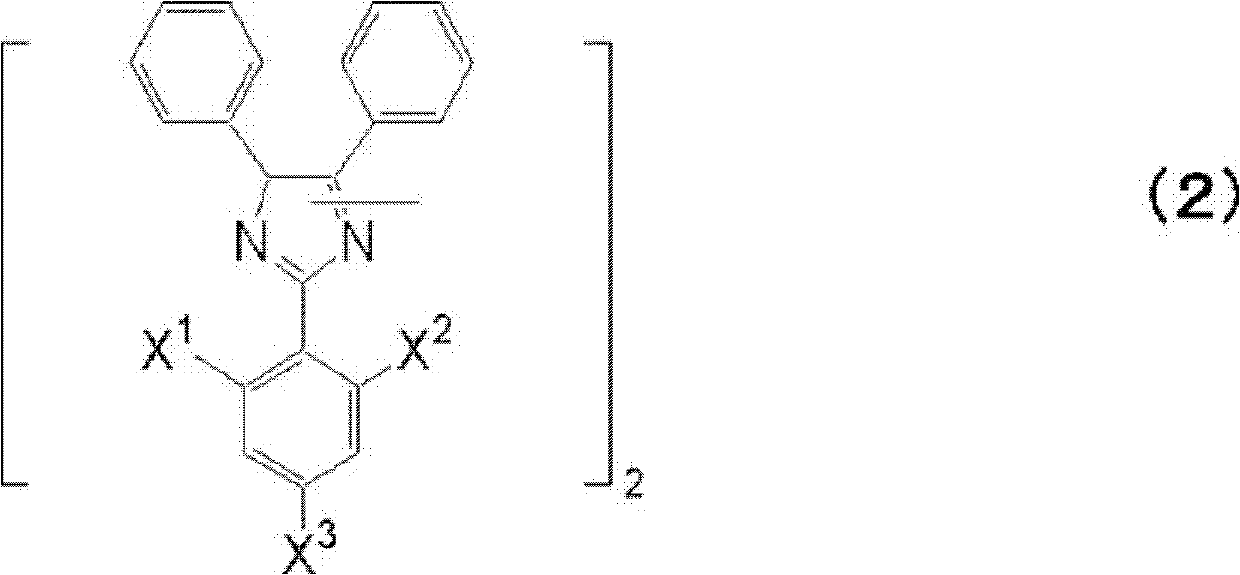

[0365] · Photopolymerization initiator: 0.14 parts of 2-chlorophenyl-4,5-bisphenylimidazole dimer (B-CIM, manufactured by HODOGAYA Chemical Co., Ltd.)

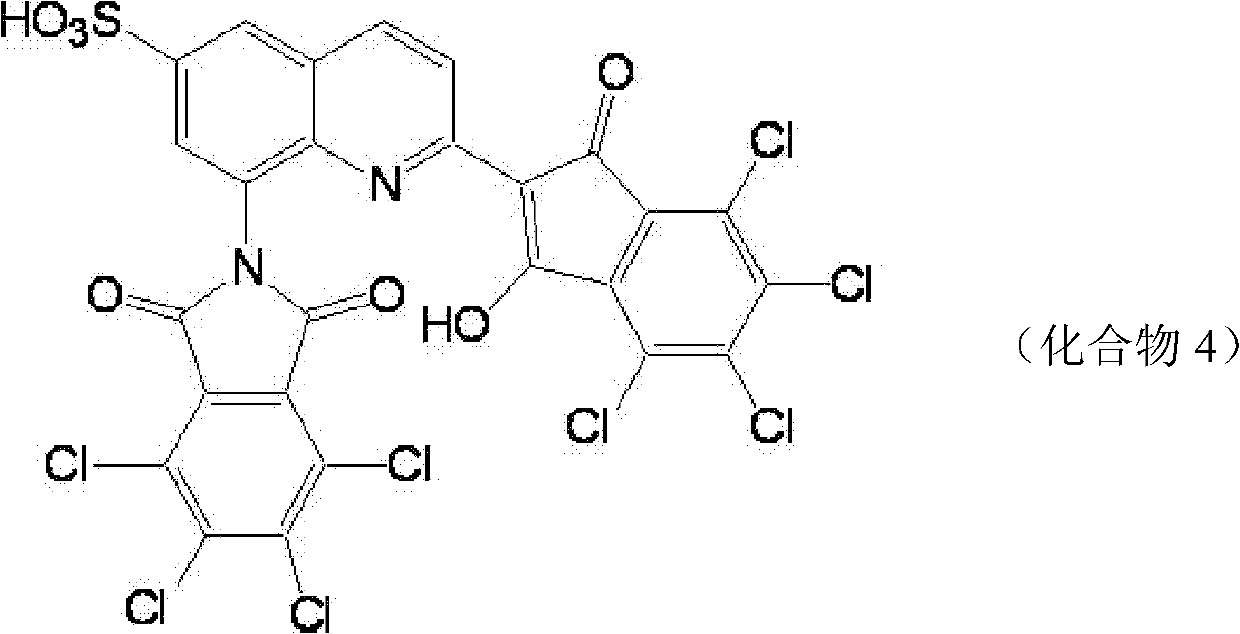

[0366] · Photopolymerization initiator: IRGACURE OXE01 (manufactured by Ciba Specialty Chemicals Co., Ltd., structure shown below) 1.47 parts

[0367] Ali...

Embodiment 2~12、 comparative example 1~8

[0385] In the composition 1 of Example 1, the types of the pigment dispersion composition, polymerizable monomer, photopolymerization initiator, and chain transfer agent (aliphatic thiol compound) were changed as described in Table 1, except that Each colored photosensitive composition of Examples 2-12 and Comparative Examples 1-8 was prepared similarly to Example 1.

[0386] Using each obtained colored photosensitive composition, except having changed the exposure system in an exposure process as described in Table 1, it carried out similarly to Example 1, and produced the colored pattern.

[0387] In Table 1, the pigment dispersion composition is a pigment dispersion composition indicated by the name of the pigment.

[0388] In addition, the detail of the exposure system described as "proximity type" in Table 1 is the exposure system (proximity type exposure) applied to the exposure process in Example 1. In addition, the details of the exposure method described as "laser" a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com