Dyeing photosensitive resin combination, colorful color filter and liquid crystal display apparatus with colorful color filter

A technology of photosensitive resin and composition, applied in the field of liquid crystal display device and colored photosensitive resin composition, can solve the problems of decreased brightness, contamination of exposure machines, poor color characteristics, etc., and achieves excellent sensitivity, excellent and high quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

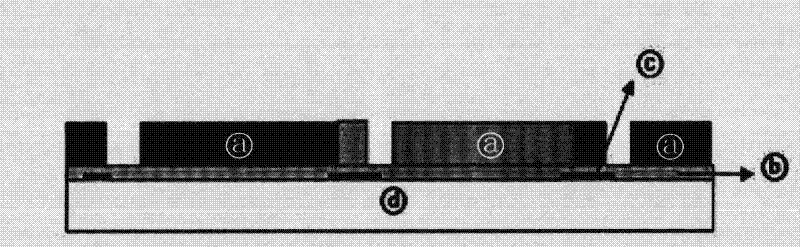

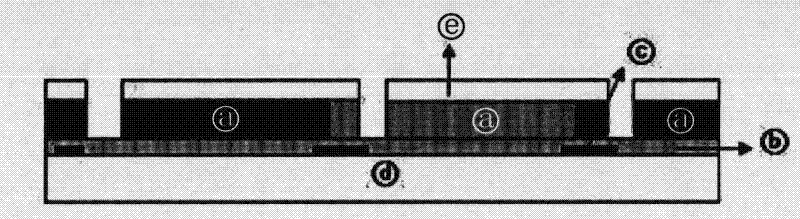

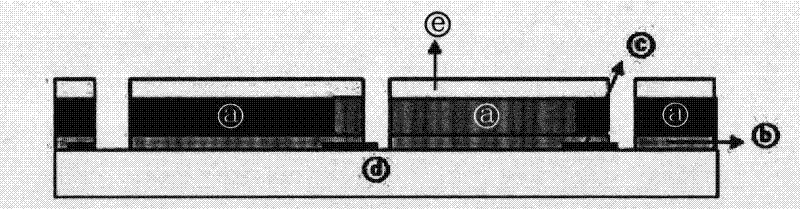

Image

Examples

Synthetic example

[0188]

[0189] In a flask with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen introduction tube, mix and introduce 90g propylene glycol monomethyl ether acetate, 90g propylene glycol monomethyl ether, and 11.0g 2-norbornene (2- norbornene) (0.10mol), after replacing the air in the flask with nitrogen, the temperature was raised to 80°C, and the following solution was added dropwise from the dropping funnel to the flask for 2 hours. The solution contained 70.5g benzyl Add 3.2g tert-butyl peroxy 2-ethylhexyl carbonate in the mixture of methacrylate (0.4mol), 45.0g methacrylic acid (0.5mol) and 136g propylene glycol monomethyl ether acetate, at 100 Stirring was continued for 5 hours at °C. Then, the nitrogen in the flask was replaced with air, and 30 g of glycidyl methacrylate [0.2 mol (40 mol % of the carboxyl group of methacrylic acid used in the present invention)], 0.9 g of tris(dimethylaminomethyl) base) phenol and 0.145 g of hydroquinone...

Embodiment 1~4 and comparative example 1~5

[0192] Among the components shown in the following Table 1, the pigment as (A) coloring material and the pigment dispersant as (F) other additives are mixed in advance until the total amount accounts for the pigment, pigment dispersant and propylene glycol alone in percentage by mass. 20% by mass of the total amount of methyl ether acetate mixed, the pigment is fully dispersed with a bead mill, and then the beads are separated, and the remaining components containing the remaining propylene glycol monomethyl ether acetate are further added and mixed to obtain a colored photosensitive resin combination.

[0193] Table 1

[0194]

[0195] The constituent components used in Table 1 are as follows.

[0196] Coloring material (A1): blue pigment dispersion liquid (C.I. Pigment Green 58).

[0197] Coloring material (A2): Yellow pigment dispersion liquid (C.I. Pigment Yellow 150).

[0198] Photopolymerizable compound (C): dipentaerythritol hexaacrylate (KAYARAD DPHA; manufacture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com