Method for producing large high-purity molybdenum planar target material for flat panel displays

A production process and display technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve problems such as uneven coating thickness, fragility, and large fracture risk, and improve product quality and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

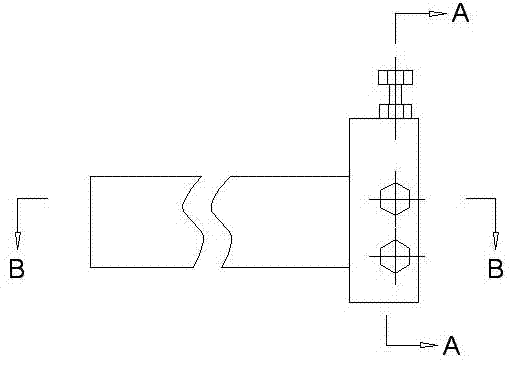

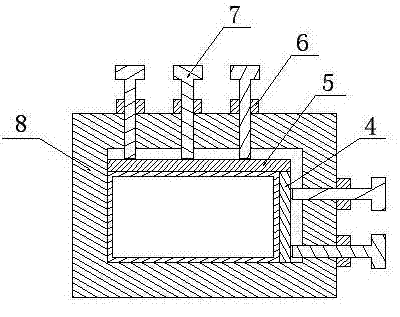

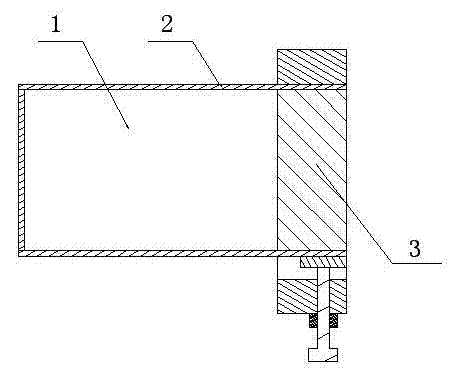

Image

Examples

Embodiment Construction

[0085] The embodiments of the present invention are given to illustrate the present invention, but do not constitute any limitation to the present invention.

[0086] Taking the finished product specification length × width × height = 1700mm × 200mm × 20mm as an example, according to the characteristics and technical requirements of large-scale high-purity molybdenum planar targets, the processing technology is determined as follows:

[0087] 1. Molybdenum powder analysis: brand: FMo-1, use ICP atomic absorption spectrometry to analyze the purity of molybdenum powder, Mo content ≥ 99.5%, control the content of impurities:

[0088] Fe<0.005;Sn<0.0005;Ni<0.003;Sb<0.010;Si<0.002;Cd<0.0005;

[0089] Al<0.0015;C<0.005;Ca<0.0015;N<0.015;Mg<0.002;O<0.2;

[0090] Cu<0.001;W<0.05;Pb<0.0005;Bi<0.0005

[0091] 2. Powder selection: Use a 200-mesh sieve to screen the molybdenum powder;

[0092] 3. Powder blending: the purpose is to obtain powders with different particle size combination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com