Recombinant phage vaccine for avian influenza A and construction method for recombinant phage vaccine

A construction method and bacteriophage technology, which can be used in pharmaceutical formulations, antibody medical components, virus antigen components, etc., can solve problems such as difficulties in the production and supply of influenza vaccines and implementation of immunization, antigenic variation, and antigenic transformation, so as to facilitate large-scale production, Easy to purify, easy to culture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Construction of recombinant phage

[0040] A DNA sequence was synthesized by a commercial company. The DNA sequence has been cloned into the multiple cloning site of the pUC-19 vector. The 5' end of the DNA sequence has a restriction site EcoRI, and the 3' end contains a restriction site HindⅢ. The DNA sequence As shown in SEQ ID NO: 3

[0041] The above DNA sequence was excised from the pUC-19 vector with restriction endonucleases EcoRI and HindIII and inserted between EcoRI and HindIII of the T7 phage multiple cloning site to construct a recombinant phage.

[0042] Recombinant pUC-19 vector double enzyme digestion system:

[0043] wxya 2 o 16.0 μL 10×H Buffer 5.0 μL pUC-19 vector 25.0 μL EcoRI 2.0 μL HindⅢ 2.0 μL

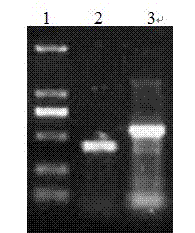

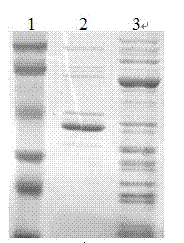

[0044] Mix the above reaction system and place it in a 37°C water bath for 4 hours. After the digested product is also identified by 1% agarose gel electrophoresis, the gel recovery kit is used for ...

Embodiment 2

[0056] Example 2 Large scale amplification of recombinant phage

[0057] Glycerol frozen E. coli Strain BL21 was inoculated on the plane of LB medium, cultured overnight at 37 °C; a single colony was picked from the plate, inoculated with 5 mL of LB culture medium, and cultured overnight at 37 °C with shaking at 200 rpm. Take 3mL overnight culture to inoculate 300mL LB culture medium, cultivate to OD 600 =0.8 or so. Pick a single phage plaque on the plate, inoculate it into the cultured BL21 host bacteria, and incubate with shaking at 37°C and 100 rpm for 2-3 hours until the bacterial solution changes from turbid to clear. The phage was recovered by PEG-NaCl precipitation, and the phage titer was determined according to the conventional method. Adjust the recovered phage concentration to 2×10 13 pfu / mL, and add formaldehyde solution at a ratio of 4‰, and inactivate overnight at 37°C and 100 rpm with shaking.

Embodiment 3

[0058] Example 3 Preparation of Type A Avian Influenza Recombinant Phage Oil Emulsion Vaccine

[0059] The preparation method of recombinant phage deodorizing oil emulsion vaccine is as follows:

[0060] Preparation of the oil phase of the vaccine: 4mL Siben 80, 2mL Siben 85, 94mL No. 10 mineral oil, 2g aluminum stearate, mix well, and press at 121°C for 20 minutes under high pressure. Preparation of vaccine aqueous phase: 94mL titer is 2×10 13 Pfu / mL of inactivated phage, 4 mL of autoclaved Tween-80, 3000 rpm and stir well. According to the ratio of water phase: oil ratio of 1:3, add 150mL oil phase to the tissue masher, slowly add 50mL water phase while stirring slowly, after mixing well, stir at 10000 rpm / quickly for 2 minutes until a stable The water-in-oil structure is the prepared recombinant phage oil emulsion vaccine, which is stored at 4°C for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com