Production process for ultra-pure N-methylpyrrolidone

A technology of methylpyrrolidone and production method, applied in directions such as organic chemistry, can solve problems such as complicated preparation process, difficult process control, etc., and achieve the effects of good effect, easy operation, and avoiding unstable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

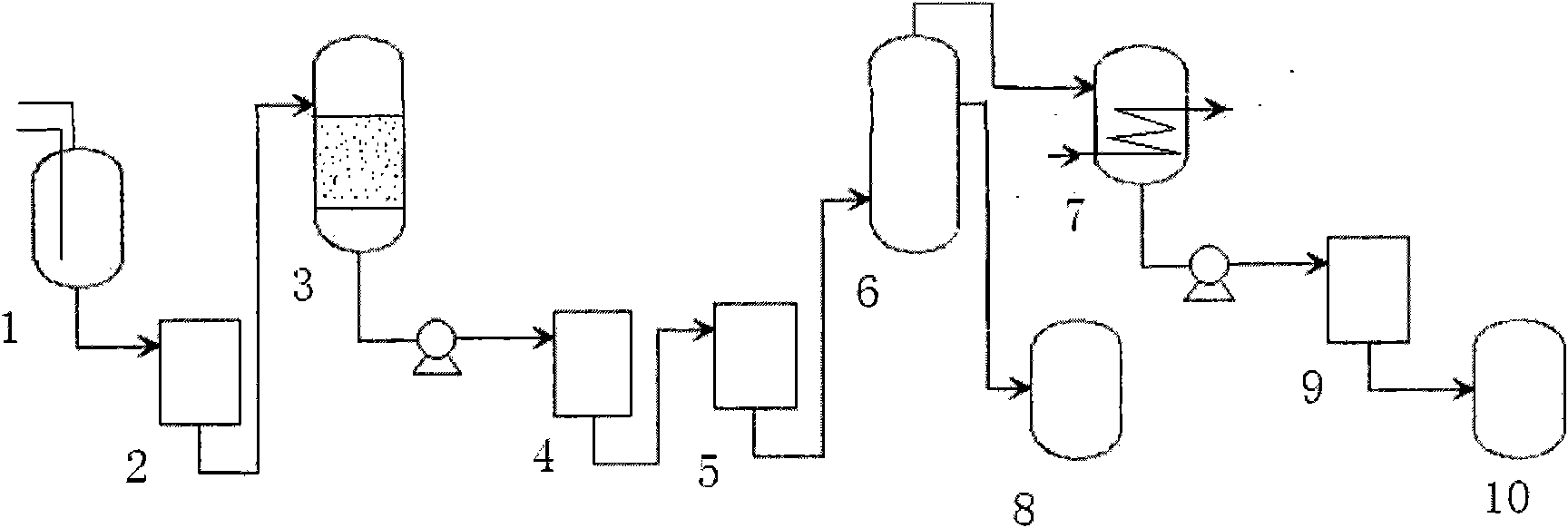

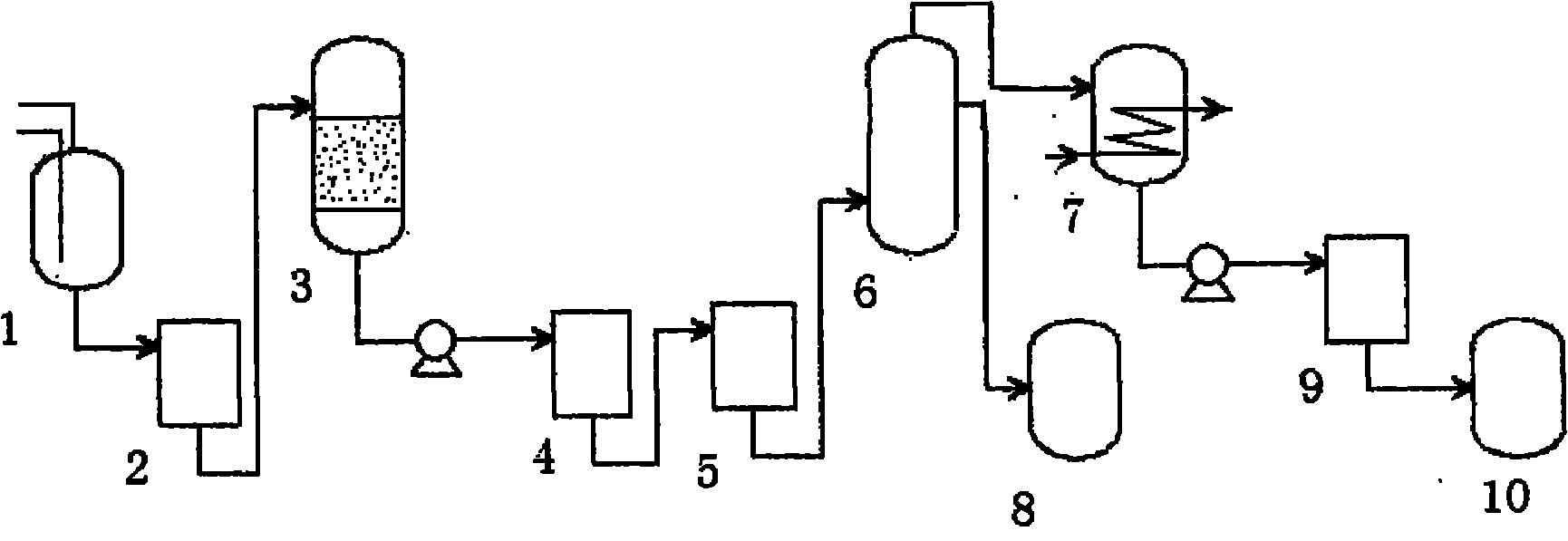

[0026] (1) Preparation of N-methylpyrrolidone pretreatment solution:

[0027] In 500L pure quartz reactor 1 equipped with heating device, stirring device, thermometer and gas distributor, add 350kg of industrial grade N-methylpyrrolidone, control the temperature at 30±5°C, and distribute the formazan through the gas distributor under agitation. Amine gas is continuously fed into technical grade N-methylpyrrolidone at a flow rate of 5L / min (feeding ratio methylamine gas: technical grade NMP=4:1, mass ratio), and maintain this temperature for 1 hour; Methylpyrrolidone is filtered through the filter 2, and then dehydrated through a Φ400×600mm 4A molecular sieve adsorber 3 at a flow rate of 6L / min at 30-40°C to obtain N-methylpyrrolidone pretreatment liquid.

[0028] (2) the production method of N-methylpyrrolidone:

[0029] The N-methylpyrrolidone pretreatment solution is passed through the first-stage membrane filter 4 and the second-stage membrane filter 5 at a pressure of 0.5...

Embodiment 2

[0032] (1) Preparation of N-methylpyrrolidone pretreatment solution:

[0033] In a pure quartz reactor with a heating device, a stirring device, a thermometer and a gas distributor, add 350kg of industrial grade N-methylpyrrolidone, control the temperature at 35±5°C, and distribute the methylamine gas through the gas distributor under agitation. Continuously feed into industrial-grade N-methylpyrrolidone at a flow rate of 6L / min (feeding ratio methylamine gas: industrial-grade NMP=6:1, mass ratio), and maintain the temperature for 1.5 hours; At a flow rate of 6L / min, dehydrate through a Φ400×600mm 4A molecular sieve adsorber, and filter to obtain N-methylpyrrolidone pretreatment liquid.

[0034] (2) the production method of N-methylpyrrolidone:

[0035] The N-methylpyrrolidone pretreatment solution is passed through a β-cyclodextrin composite membrane with a pore size of 0.2 μm under a pressure of 0.5 MPa for the first membrane filtration, and then through a 18-crown-6 compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com