Film structure and method for isolation of SiGeHBT (silicon germanium heterojunction bipolar transistor) emitter from base

A film structure and emitter technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing the amount of wet over-etching, blocking the normal etching of chemical solutions, increasing processing events, etc., to reduce wet The effect of reducing the amount of over-etching, reducing the amount of over-etching, and reducing the lateral dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

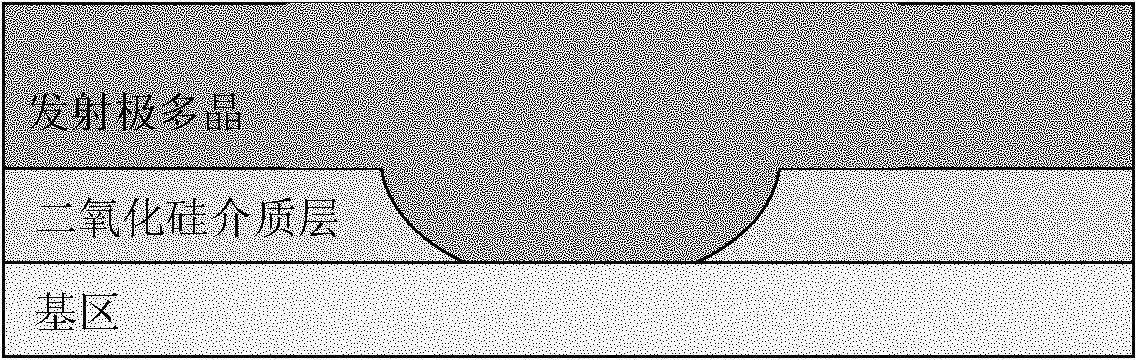

[0014] The invention proposes a new film layer structure for the isolation between the emitter and the base of the triode, and at the same time can reduce the over-etching required for opening the emitter window as little as possible and suppress the expansion of the emitter window.

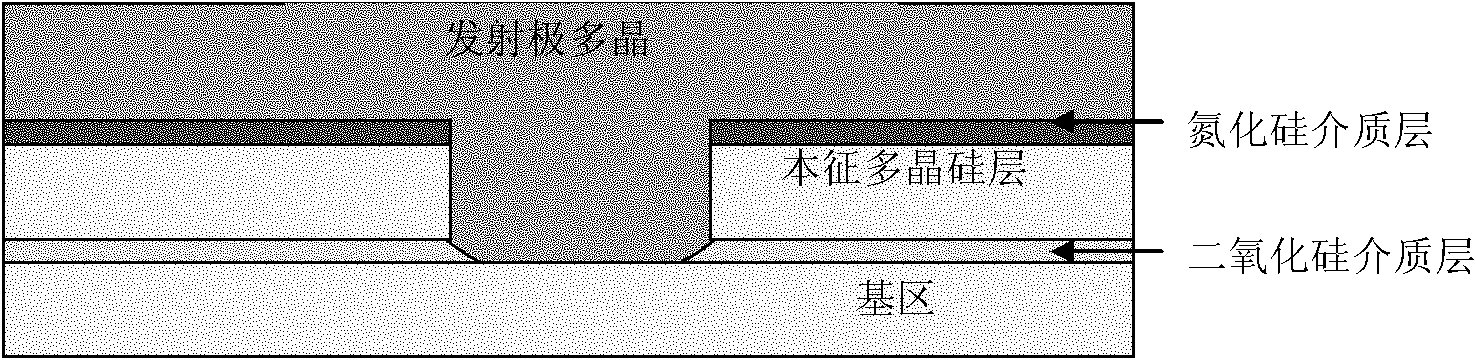

[0015] Such as figure 2 As shown, the present invention replaces the traditional single-layer film structure with a stacked structure, and the film layers of the composite stacked structure are silicon dioxide, intrinsic polysilicon and silicon nitride from bottom to top. The silicon dioxide has a thickness of 50 to 200 angstroms; the polysilicon has a thickness of 50 to 200 angstroms. The thickness of the silicon nitride is 50 to 200 angstroms.

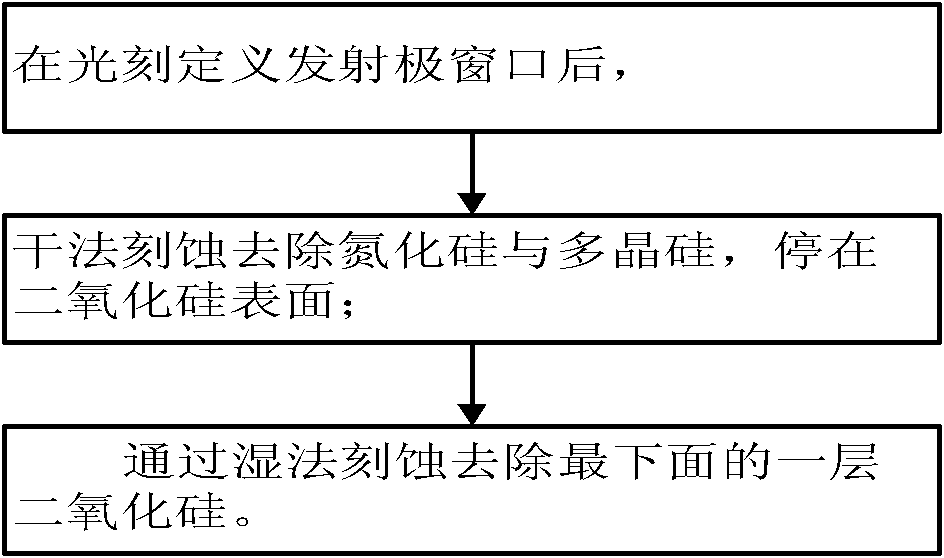

[0016] Such as image 3 As shown, the manufacturing method of the film layer structure isolated between the emitter and the base of the SiGe HBT described in the present invention includes that the etching of the emitter window is realized by two-ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com