Catalyst for preparing C2-oxygenates through hydrogenation of carbon monoxide as well as preparation method and application thereof

A technology for the preparation of carbon monoxide and hydrogen, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, organic compound preparation, hydroxyl compound preparation, etc., which can solve the problem of high catalyst preparation cost, complicated treatment conditions, and carbon dioxide oxygen-containing compounds. Poor selectivity and other problems, to achieve the effect of overcoming low conversion rate of carbon monoxide, improving dispersion and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of catalyst A that is used for carbon monoxide hydrogenation to prepare carbon two oxygen-containing compounds, it uses monodisperse SiO 2 As a carrier, its composition is Rh-Mn-Li / SiO 2 , where each metal relative to the monodisperse support SiO 2 The mass percentage of Rh:Mn:Li:SiO 2 1.5:1.5:0.075:100.

[0035]A kind of above-mentioned preparation method for the preparation method of the catalyst A of carbon monoxide hydrogenation preparation carbon two oxygen-containing compounds comprises the steps:

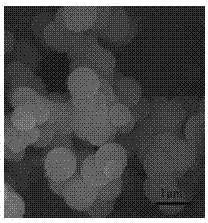

[0036] (1) Monodisperse SiO was prepared by sol-gel method 2 carrier

[0037] At 15°C, a 20% volume percent tetraethyl orthosilicate ethanol solution (50ml) was slowly dropped into a mixture of 76ml ammonia water and 210ml absolute ethanol, stirred magnetically for 2 hours, and aged for 10 hours. The resulting suspension was centrifuged and washed three times with ethanol, the resulting product was dried at 90 °C, and then calcined at 120 °C for 4 h to obta...

Embodiment 2

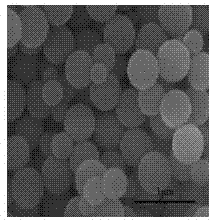

[0042] A catalyst B for the hydrogenation of carbon monoxide to prepare carbon dioxide oxygenates, monodispersed SiO in step (1) 2 The calcination temperature during the preparation of the carrier was 350 °C, and the resulting SiO 2 The SEM picture of the carrier is as follows figure 2 shown, from figure 2 It can be seen that the prepared SiO 2 monodisperse SiO 2 ;

[0043] Others are the same as in Example 1, finally obtaining catalyst B for hydrogenation of carbon monoxide to prepare carbon dioxide oxygen-containing compounds.

Embodiment 3

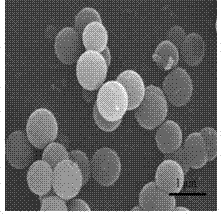

[0045] A catalyst C for carbon monoxide hydrogenation to prepare carbon dioxide oxygenates, monodisperse SiO in step (1) 2 The calcination temperature during the preparation of the carrier was 500 °C, and the obtained SiO 2 The SEM picture of the carrier is as follows image 3 shown, from image 3 It can be seen that the prepared SiO 2 monodisperse SiO 2 ;

[0046] Others are the same as in Example 1, finally obtaining catalyst C for hydrogenation of carbon monoxide to prepare carbon dioxide oxygen-containing compounds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com