Method for preparing cyclohexane by hydrogenating benzene

A technology for hydrogenation of benzene and cyclohexane, which is applied in the fields of hydrogenation to hydrocarbon production, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as the influence of hydrogenation effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

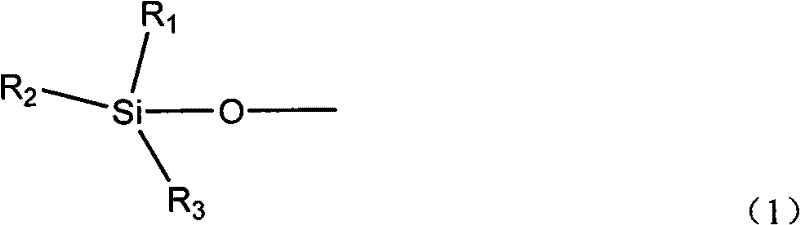

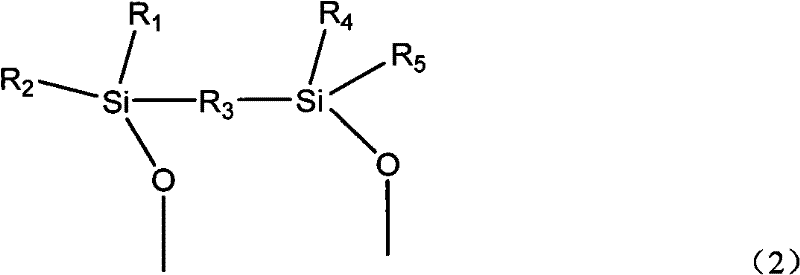

[0046] This example illustrates the preparation of the hydrogenation catalyst used in the process of the invention.

[0047] 1) Weigh 50.0 g of alumina carrier, impregnate with 35 ml of aqueous solution containing 0.90 g of potassium nitrate for 0.5 h by equal-volume impregnation method, dry at 120 °C for 4 h, and roast at 550 °C for 6 h;

[0048] 2) Then impregnate with an aqueous solution containing 50.1g of nickel nitrate in two steps by equal-volume impregnation, dry at 120°C for 4h, roast at 450°C for 6h, and reduce in a hydrogen atmosphere at 400°C for 20h;

[0049] 3) Silylation treatment with methyltriethoxysilane at 120° C. for 1.5 h to obtain catalyst A-1. See Table 1 for the catalyst composition.

Embodiment 2

[0051] This example illustrates the preparation of the hydrogenation catalyst used in the process of the invention.

[0052] 1) Weigh 50 g of alumina carrier, impregnate with 35 ml of aqueous solution containing 2.43 g of magnesium nitrate by equal volume impregnation method for 0.5 h, dry at 120 °C for 4 h, and roast at 550 °C for 6 h;

[0053] 2) Then impregnate with an aqueous solution containing 120.4g of nickel nitrate in two steps using an equal-volume impregnation method for 0.5h, dry at 120°C for 4h, roast at 450°C for 6h, and reduce in a hydrogen atmosphere at 400°C for 20h;

[0054] 3) Silylation treatment with methyltriethoxysilane at 120° C. for 1.5 h to obtain catalyst A-2. See Table 1 for the catalyst composition.

Embodiment 3

[0056] This example illustrates the preparation of the hydrogenation catalyst used in the process of the invention.

[0057] 1) Weigh 50.0 g of alumina carrier, impregnate with 35 ml aqueous solution containing 1.82 g of cerium nitrate for 0.5 h by equal-volume impregnation method, dry at 120 °C for 4 h, and roast at 550 °C for 6 h;

[0058] 2) Then impregnate with an aqueous solution containing 50.0 g of nickel nitrate in two steps using an equal-volume impregnation method for 0.5 h, dry at 120 ° C for 4 h, roast at 450 ° C for 6 h, and reduce in a hydrogen atmosphere at 400 ° C for 20 h;

[0059] 3) Silylation treatment with methyltriethoxysilane at 120° C. for 1.5 h to obtain catalyst A-3. See Table 1 for the catalyst composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com