Preparation method for monodisperse cationic polystyrene microballoon sphere with controllable grain diameter

A polystyrene microsphere, cationic technology, applied in the field of preparation of monodisperse cationic polystyrene microspheres, can solve the problems of difficult control of reaction conditions, uneven particle size distribution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

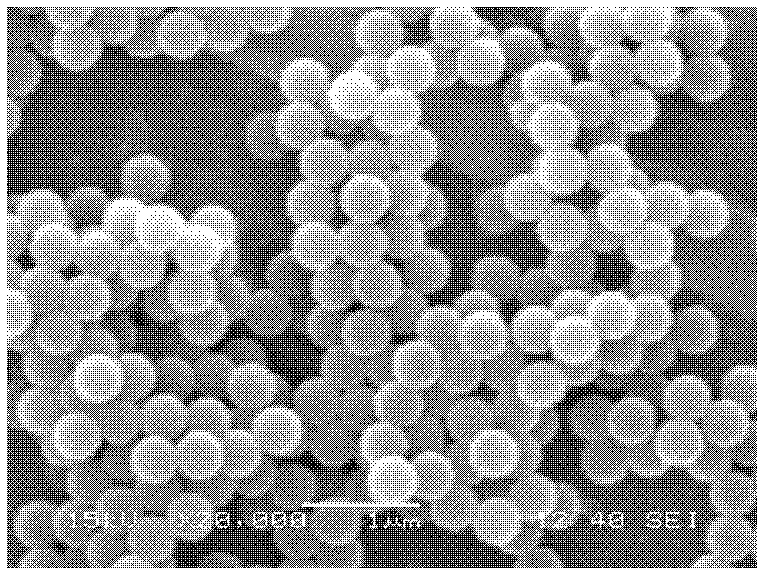

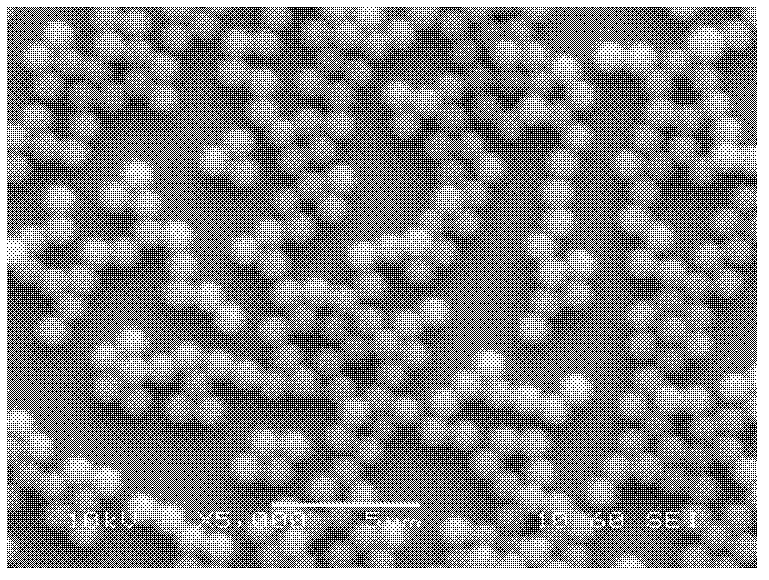

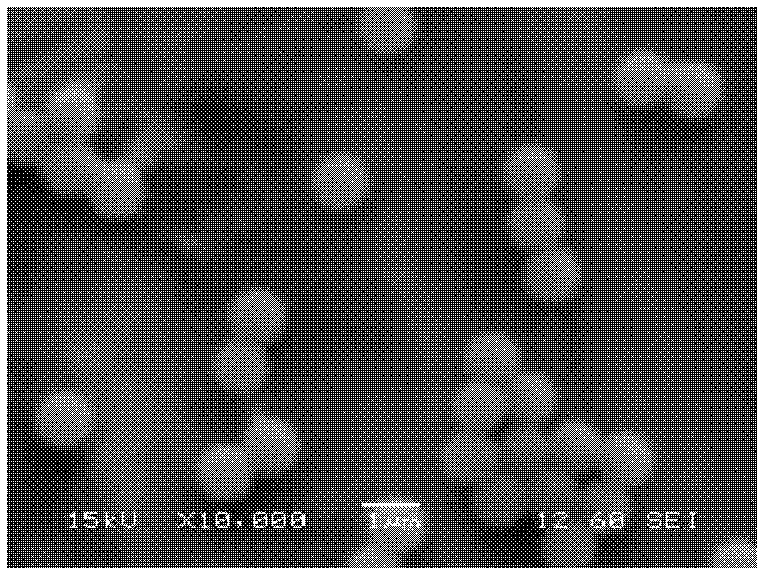

example 1

[0021] Commercially available styrene (analytical pure) was removed with 5wt% sodium hydroxide solution to remove the polymerization inhibitor, then washed with deionized water until neutral, dried with anhydrous calcium chloride, and then subjected to vacuum distillation for later use.

[0022] Mix 10ml of deionized water and 30ml of methanol into a 100ml three-necked flask, under the protection of nitrogen, mix 5ml of styrene, 0.25g of azobisisobutylamidine hydrochloride (V-50), and 0.5ml of hydroxyethyl acrylate Add it into a three-necked flask, mix and stir, heat, the stirring speed is 200 rpm, and react for 6 hours at a temperature of 70°C. After the reaction stopped, cool down to room temperature naturally, use a high-speed centrifuge to centrifuge, discard the supernatant, wash the precipitate with ethanol, disperse it with ultrasonic waves for 5 minutes, continue centrifuging to obtain the precipitate, and dry it in a vacuum oven at 50°C. That is, monodisperse cationic...

example 2

[0024] Commercially available styrene (analytical pure) was removed with 5wt% sodium hydroxide solution to remove the polymerization inhibitor, then washed with deionized water until neutral, dried with anhydrous calcium chloride, and then subjected to vacuum distillation for later use.

[0025] Mix 12ml of deionized water and 28ml of ethanol into a 100ml three-neck flask, under nitrogen protection, mix 7ml of styrene, 0.5g of azobisisobutylamidine hydrochloride (V-50), and 1.0ml of hydroxyethyl acrylate Add it into a three-necked flask, mix and stir, heat, the stirring speed is 200 rpm, and react for 6.5 hours at a temperature of 75°C. After the reaction stopped, cool down to room temperature naturally, use a high-speed centrifuge to centrifuge, discard the supernatant, wash the precipitate with ethanol, disperse it with ultrasonic waves for 5 minutes, continue centrifuging to obtain the precipitate, and dry it in a vacuum oven at 50°C. That is, monodisperse cationic polystyr...

example 3

[0027] Commercially available styrene (analytical pure) was removed with 5wt% sodium hydroxide solution to remove the polymerization inhibitor, then washed with deionized water until neutral, dried with anhydrous calcium chloride, and then subjected to vacuum distillation for later use.

[0028] Mix 14ml of deionized water and 26ml of methanol into a 100ml three-necked flask, under nitrogen protection, add 9ml of styrene, 0.7g of azobisisobutylamidine hydrochloride (V-50), and 2ml of hydroxyethyl acrylate Mix, stir and heat in a three-necked flask at a stirring speed of 200 rpm, and react for 7 hours at a temperature of 80°C. After the reaction stopped, cool down to room temperature naturally, use a high-speed centrifuge to centrifuge, discard the supernatant, wash the precipitate with ethanol, disperse it with ultrasonic waves for 5 minutes, continue centrifuging to obtain the precipitate, and dry it in a vacuum oven at 50°C. That is, monodisperse cationic polystyrene microsp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com