Coupled denitration system

A coupling type, denitrification technology, applied in the field of electric power and energy, can solve problems affecting the human respiratory system, human health, and the ozone layer, and reduce the limit of low-load stable combustion and fuel injection, expand adaptability, and simple system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

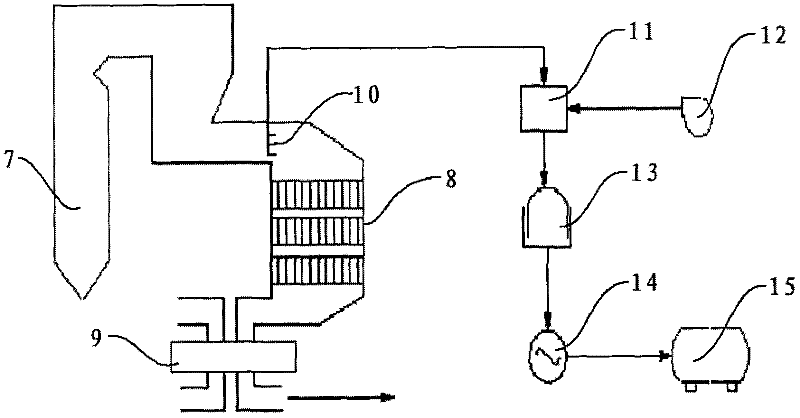

[0052] Such as image 3 As shown, the coupled denitrification system includes a boiler 7 equipped with dual-channel burners, the boiler 7 is connected to the catalytic reaction chamber 8, and an ammonia injection grid 10 is arranged in the pipeline at the entrance of the catalytic reaction chamber 8. The ammonia grid 10 is connected with the external ammonia gas supply system through a pipeline, the outlet of the catalytic reaction chamber 8 is located at the bottom and an air preheater 9 is arranged at the lower outlet of the catalytic reaction chamber, and the inside of the catalytic reaction chamber 8 is vertically The setup has multiple reactive layers.

[0053] The ammonia gas supply system comprises a liquid ammonia storage tank 15, an ammonia evaporator 14, an ammonia buffer tank 13, an ammonia air mixer 11 and a dilution fan 12, and the liquid ammonia storage tank 15 is connected with the ammonia evaporator 14, and ammonia evaporates Device 14 is delivered to ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com