Liquid dairy product for improving physique of old people and production method thereof

A dairy and liquid technology, applied in the field of dairy product processing, can solve problems such as easy side effects, cure the symptoms but not the root cause, and achieve the effects of preventing stroke and heart disease, increasing food intake, and improving symptoms of anemia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

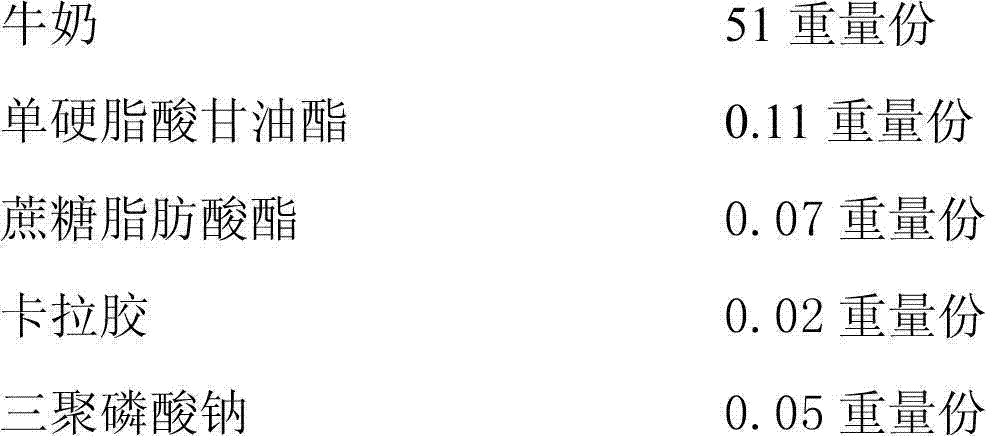

[0045] One, prepare the liquid milk product of the present embodiment according to the following ratio of raw materials:

[0046]

[0047]

[0048] Raw material standard:

[0049] Milk: in line with GB6914 standard

[0050] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0051] Two, the production method of the liquid milk product of the present embodiment comprises the following steps successively:

[0052] (1) The raw milk whose temperature does not exceed 8°C is removed through the milk cleaning process, and then pasteurized at 72°C for 10 seconds, and then cooled to below 8°C for use;

[0053] (2) Heat the pasteurized raw milk to 70°C, add glyceryl monostearate, sucrose fatty acid ester, carrageenan, sodium tripolyphosphate, soybean protein, soluble dietary fiber, CPP, folic acid, lactoferrin egg white and zinc gluconate, keep stirring in this temperature range for about 30 minutes, stir and mix evenly, and ob...

Embodiment 2

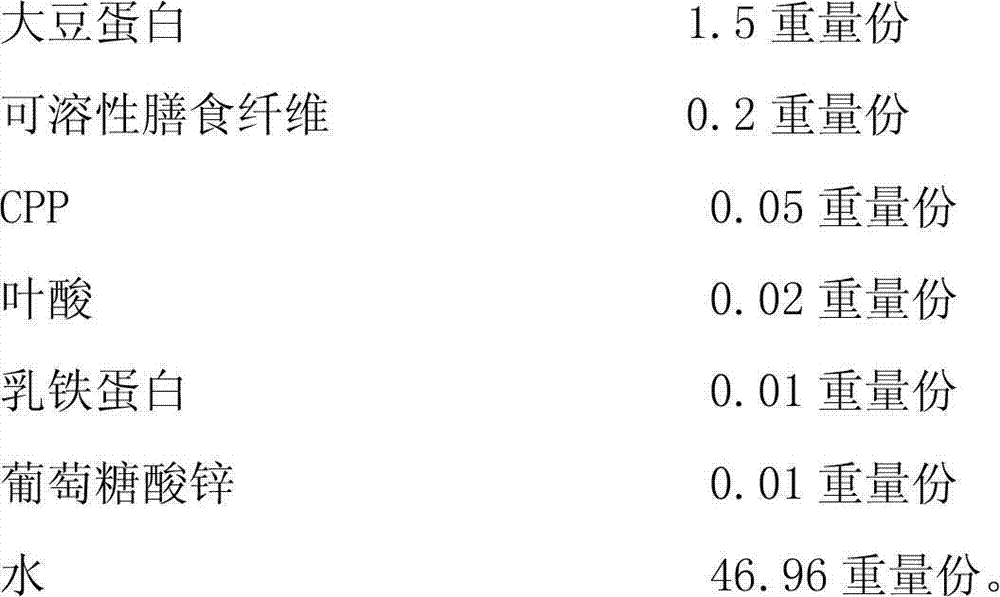

[0058] Two, prepare the liquid milk product of the present embodiment according to the following ratio of raw materials:

[0059]

[0060]

[0061] Raw material standard:

[0062] Milk: in line with GB6914 standard

[0063] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0064] Two, the production method of the liquid milk product of the present embodiment comprises the following steps successively:

[0065] (1) The raw milk whose temperature does not exceed 8°C is removed through the milk cleaning process, and then pasteurized at 72°C for 10 seconds, and then cooled to below 8°C for use;

[0066] (2) Heat the pasteurized raw milk to 65°C, add glyceryl monostearate, sucrose fatty acid ester, carrageenan, sodium tripolyphosphate, soybean protein, soluble dietary fiber, CPP, folic acid, lactoferrin egg white and zinc gluconate, keep stirring in this temperature range for about 30 minutes, stir and mix evenly, and ob...

Embodiment 3

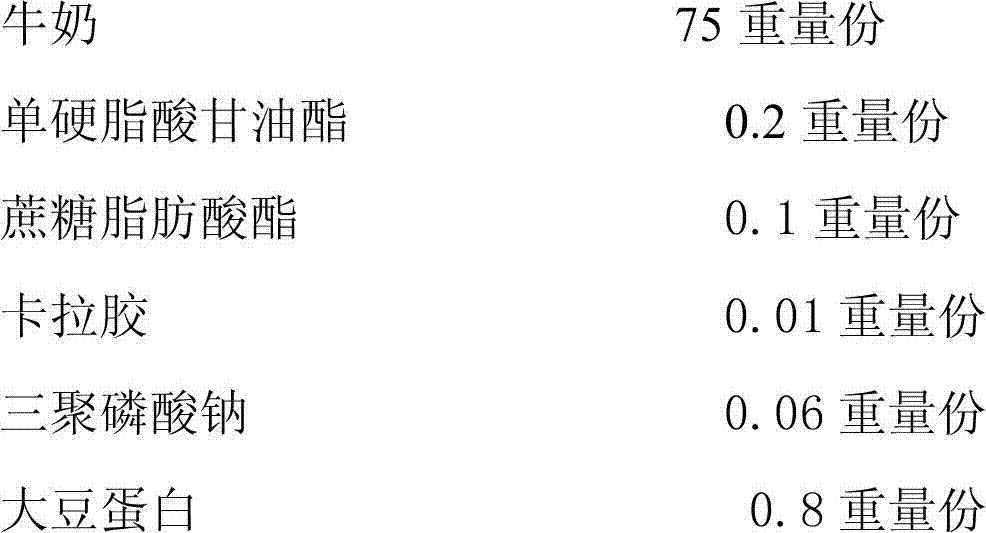

[0071] Three, prepare the liquid milk product of the present embodiment according to the following ratio of raw materials:

[0072]

[0073]

[0074] Raw material standard:

[0075] Milk: in line with GB6914 standard

[0076] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0077] Two, the production method of the liquid milk product of the present embodiment comprises the following steps successively:

[0078] (1) The raw milk whose temperature does not exceed 8°C is removed through the milk cleaning process, and then pasteurized at 72°C for 10 seconds, and then cooled to below 8°C for use;

[0079] (2) Heat the pasteurized raw milk to 65°C, add glyceryl monostearate, sucrose fatty acid ester, carrageenan, sodium tripolyphosphate, soybean protein, soluble dietary fiber, CPP, folic acid, lactoferrin egg white and zinc gluconate, keep stirring in this temperature range for about 30 minutes, stir and mix evenly, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com