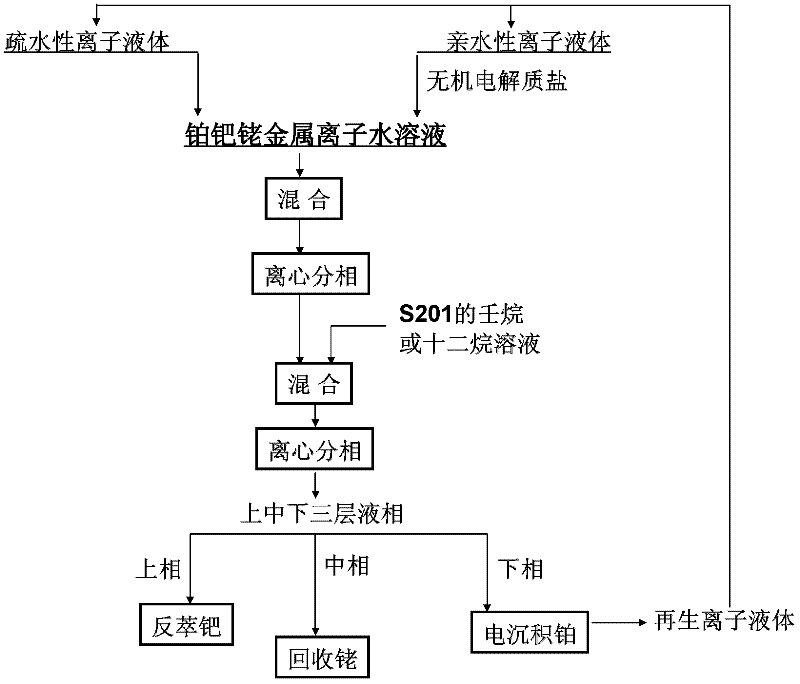

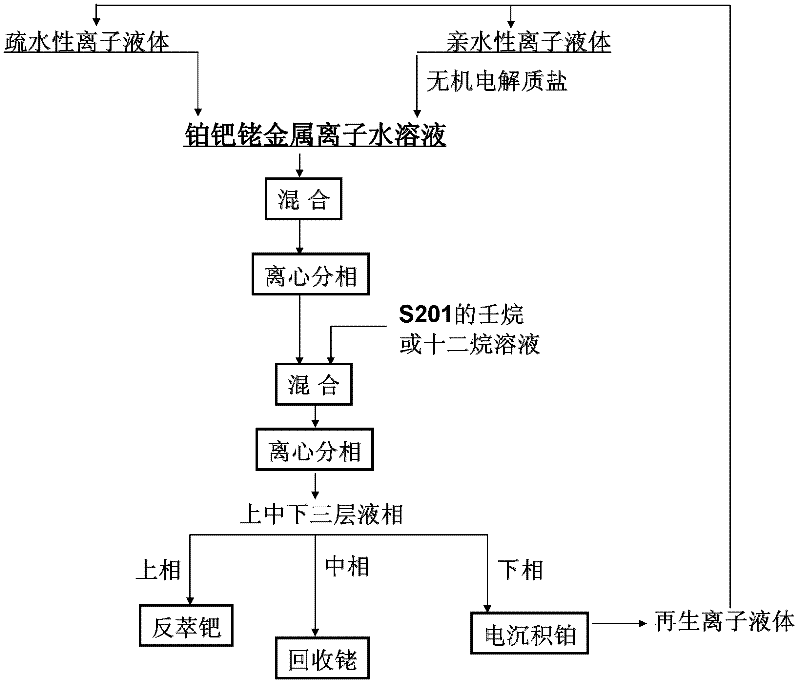

Method for extracting and separating platinum, palladium and rhodium by using ionic liquid-based three-liquid phase system

A technology of ionic liquid and three liquid phases, which can be applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problem of low separation selectivity and achieve the effects of high separation selectivity, easy hydrophilicity and hydrophobicity, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve platinum, palladium and rhodium chloride in 5 mL of 0.1 mol / L aqueous hydrochloric acid solution to prepare a metal mixed solution containing platinum, palladium and rhodium ions. The concentrations of the three metal ions are all 100 mg / L. Add 2.5 mL of ionic liquid 1-butyl-3-methylimidazolium hexafluorophosphate ([C4mim][PF 6 ]). After fully shaking and mixing at room temperature, centrifugation is carried out to obtain a two-liquid phase system in which upper and lower layers coexist. Then 5 mL of diisoamyl sulfide (S201)-dodecane organic mixed solution was added, and the weight percent concentration of S201 in dodecane was 30 wt%. After fully shaking and mixing at room temperature, the mixture is subjected to centrifugation to obtain a three-liquid-phase coexistence system of upper, middle and lower layers that are mutually immiscible and clear and separated. Get upper, middle and lower three phases and measure palladium, rhodium, platinum concentration r...

Embodiment 2

[0029] Dissolve platinum, palladium and rhodium chlorides with 5mL of hydrochloric acid aqueous solution with a concentration of 3mol / L to prepare a metal mixed solution containing platinum, palladium and rhodium ions. The concentrations of the three metal ions are all 100mg / L. Add 5 mL of ionic liquid 1-butyl-3-methylimidazolium hexafluorophosphate ([C4mim][PF 6 ]). After fully shaking and mixing at room temperature, centrifugation is carried out to obtain a two-liquid phase system in which upper and lower layers coexist. Then 5 mL of diisoamyl sulfide (S201)-nonane organic mixed solution was added, and the weight percent concentration of S201 in nonane was 50 wt%. After fully shaking and mixing at room temperature, the mixture is subjected to centrifugation to obtain a three-liquid-phase coexistence system of upper, middle and lower layers that are mutually immiscible and clear and separated. Get upper, middle and lower three phases and measure palladium, rhodium, platinum...

Embodiment 3

[0031] Dissolve platinum, palladium and rhodium chloride with 5 mL of 1mol / L aqueous hydrochloric acid solution to prepare a mixed metal solution containing platinum, palladium and rhodium ions. The concentrations of the three metal ions are all 300 mg / L. Add 10 mL of ionic liquid 1-butyl-3-methylimidazolium hexafluorophosphate ([C4mim][PF 6 ]). After fully shaking and mixing at room temperature, centrifugation is carried out to obtain a two-liquid phase system in which upper and lower layers coexist. Then 10 mL of di-n-octyl sulfide (DOS)-dodecane organic mixed solution was added, and the weight percent concentration of DOS in dodecane was 30 wt%. After fully shaking and mixing at room temperature, the mixture is subjected to centrifugation to obtain a three-liquid-phase coexistence system of upper, middle and lower layers that are mutually immiscible and clear and separated. Get upper, middle and lower three phases and measure palladium, rhodium, platinum concentration res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com