Czochralski silicon monocrystal growth furnace and method for filling silicon melts continuously

A growth furnace and silicon melt technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of high energy consumption, large furnace size, and low efficiency, so as to reduce oxygen concentration and improve production efficiency , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

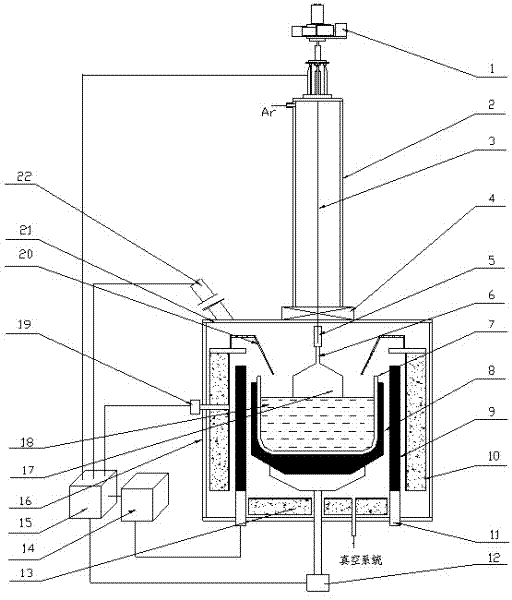

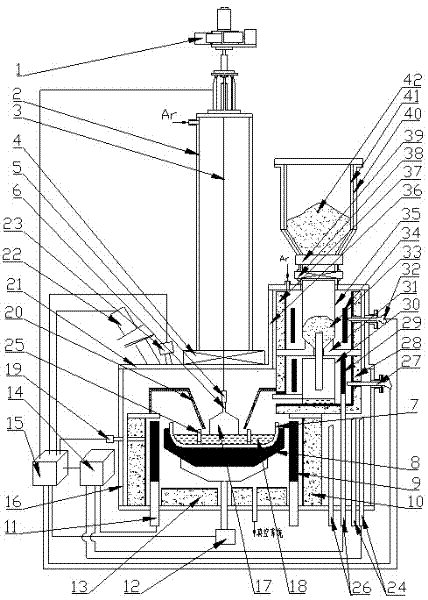

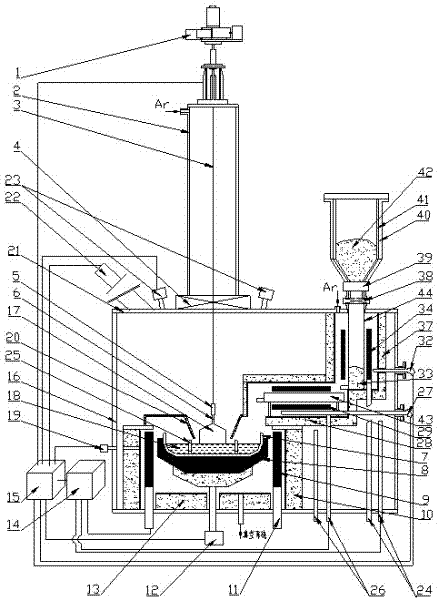

[0038] Such as figure 2 As shown, the type I Czochralski silicon single crystal growth furnace with continuous filling of silicon melt is: the left side of the growth furnace body is provided with a lifting head 1, an auxiliary furnace chamber 2, an isolation valve 4, and a furnace in sequence from top to bottom. Cover 21, furnace body 16, electrode 11, crucible lifting and rotating mechanism 12, isolation valve 4 is installed above furnace cover 21, auxiliary furnace chamber 2 is installed above isolation valve 4, and pulling head 1 is installed on the side of auxiliary furnace chamber 2 Above, the furnace cover 21 covers the furnace body 16, the lower heat insulator 13 is installed on the bottom of the furnace body 16, and the heat insulator 10 and the upper heat insulation cover 20 are installed in the furnace body 16 in order from the bottom up, and after passing through the furnace body Install the heater 9 on the electrode 11 at the bottom of 16, install the graphite cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com