Modular constant-temperature multi-filter cylinder oil mist purifying and deslagging filtration system

A filter system and modular technology, applied in the field of machinery, can solve the problems of increased operating costs such as land occupation, purchase and maintenance, scrapping of workpieces and tools, and increased rate of defective products, so as to save labor replacement costs and avoid overflow and waste , The effect of reducing the defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

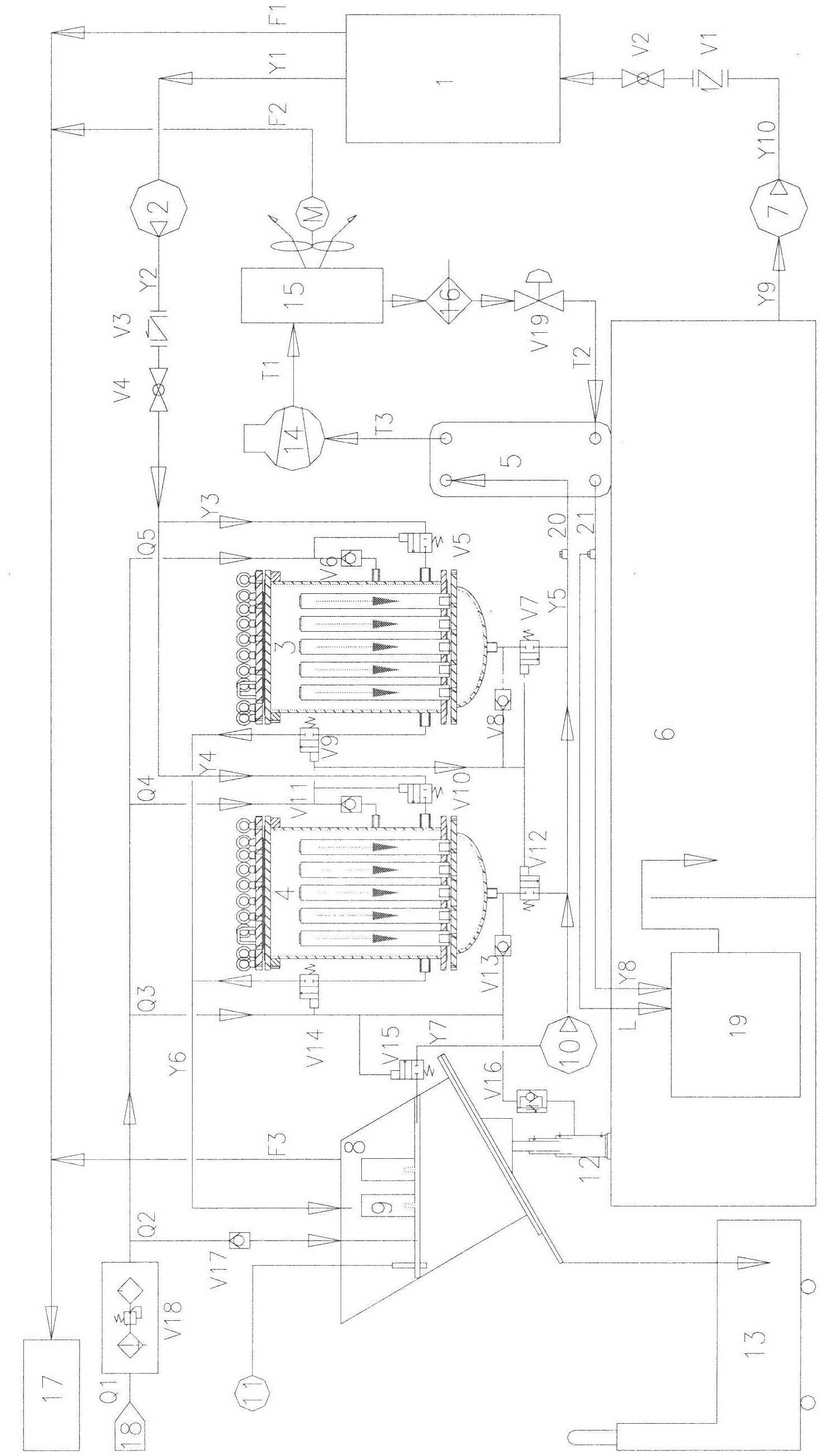

[0038] Aiming at the deficiencies in the existing technology, the inventor of this case proposed the modular constant temperature multi-filter barrel oil mist purification and slag discharge filtration system after long-term research and practice, which includes the following components integrated:

[0039] A dirty oil collection device for collecting dirty oil from the machine platform, preferably an oil pump;

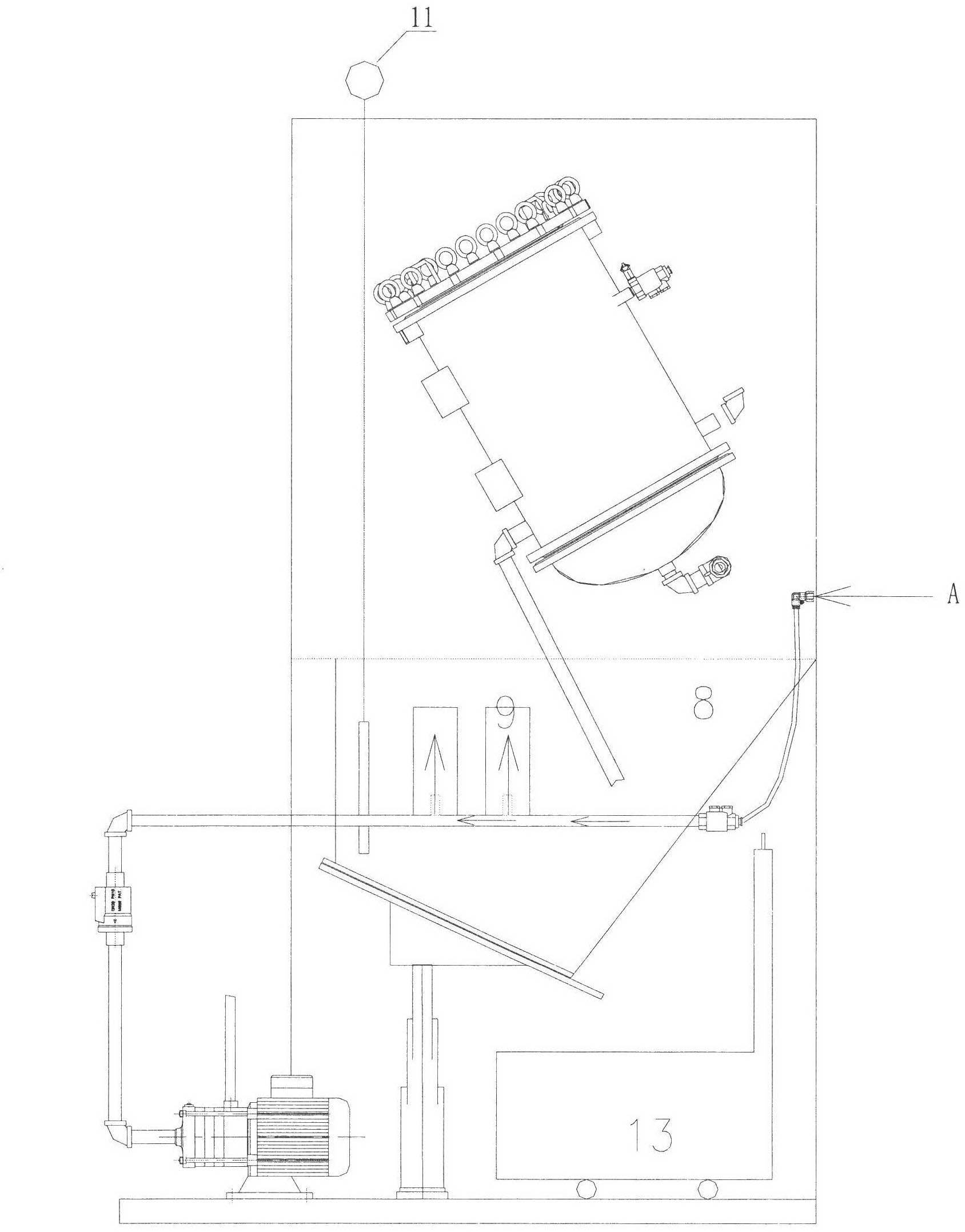

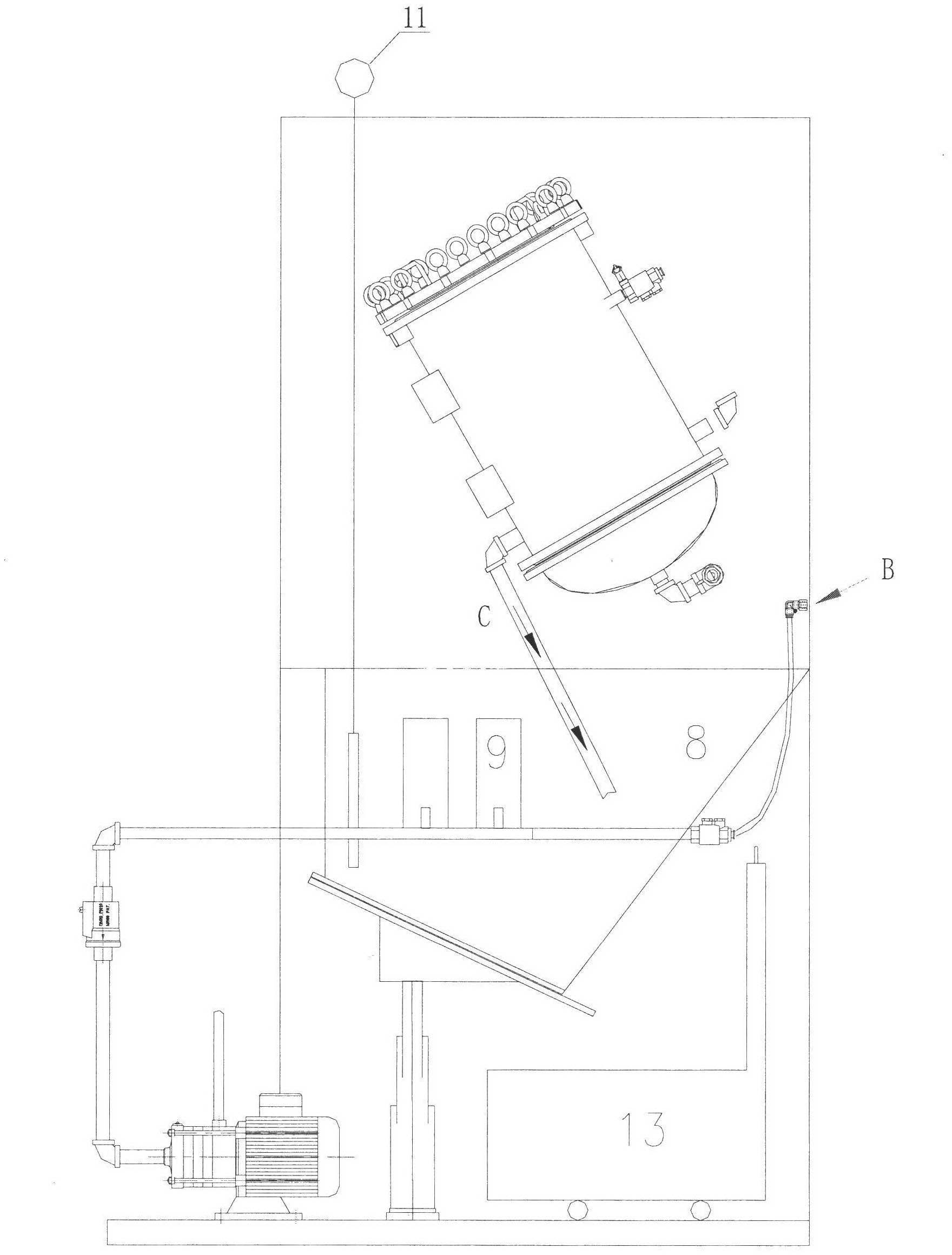

[0040] Two or more dirty oil filtering devices that are respectively connected to the dirty oil collection device and can operate simultaneously and / or in turn are preferably used as filter barrels proposed by the inventor of the present case in the invention patent applications of publication numbers CN102091479A and CN102107096A, etc., of course It is also not limited to this;

[0041] A backwash mechanism for alternately backwashing the filter elements in the two or more dirty oil filter devices, the backwash mechanism being respectively connected to the two or mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com