Graphene-platinum nano-composite catalyst for lithium air battery, and preparation method thereof

An empty battery and catalyst technology, applied in the field of electrochemistry, can solve problems such as large overvoltage, poor cycle performance, and obstacles to the application of lithium-air batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

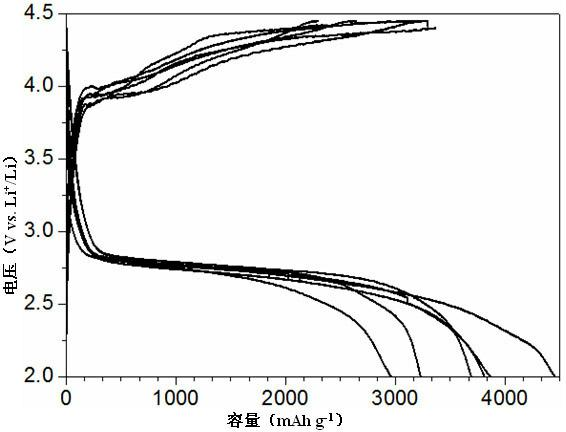

[0016] Example: When the graphene-platinum (RGO-Pt) nanocomposite catalyst is prepared by the liquid phase pulsed laser ablation technology (LP-PLA), the solid metal material platinum (Pt) is used as the laser ablation target, and the 355nm laser is powered by Nd : YAG (DCR-150, Spectra Physics) generated 1064nm base frequency after triple frequency, repetition frequency 10Hz, pulse width 10ns, energy density is about 3J / cm 2 , The ablation time is 15-60min. The dispersed graphene colloid was used as the liquid phase medium and placed in a 5 mL beaker. Fix the target in the beaker, perpendicular to the light path. The laser is focused on the target at the liquid surface, and the graphene dispersion colloid is stirred with a magnet during laser ablation.

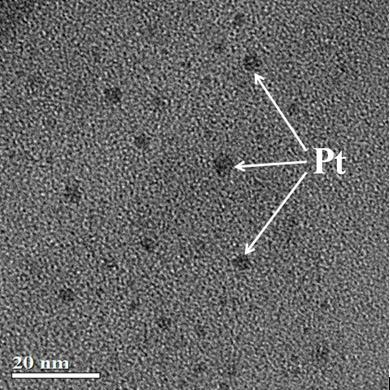

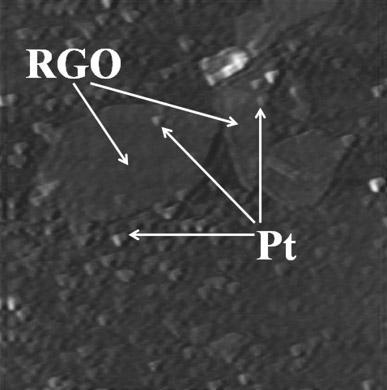

[0017] HRTEM measurement shows the material structure of graphene-platinum (RGO-Pt) nanocomposite catalyst material (attached figure 1 ).

[0018] AFM measurement shows the surface morphology of the graphene-platinum (RGO-Pt) na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com