Air blowing dehumidifying and heating steam boiler system with deaerator

A deaerator and boiler technology, applied in the direction of blasting equipment, lighting and heating equipment, machine operation mode, etc., can solve the problems of increasing smoke exhaust heat loss, consuming large oxygen, increasing power consumption, etc., and reducing moisture content. , The effect of reducing power consumption and reducing air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

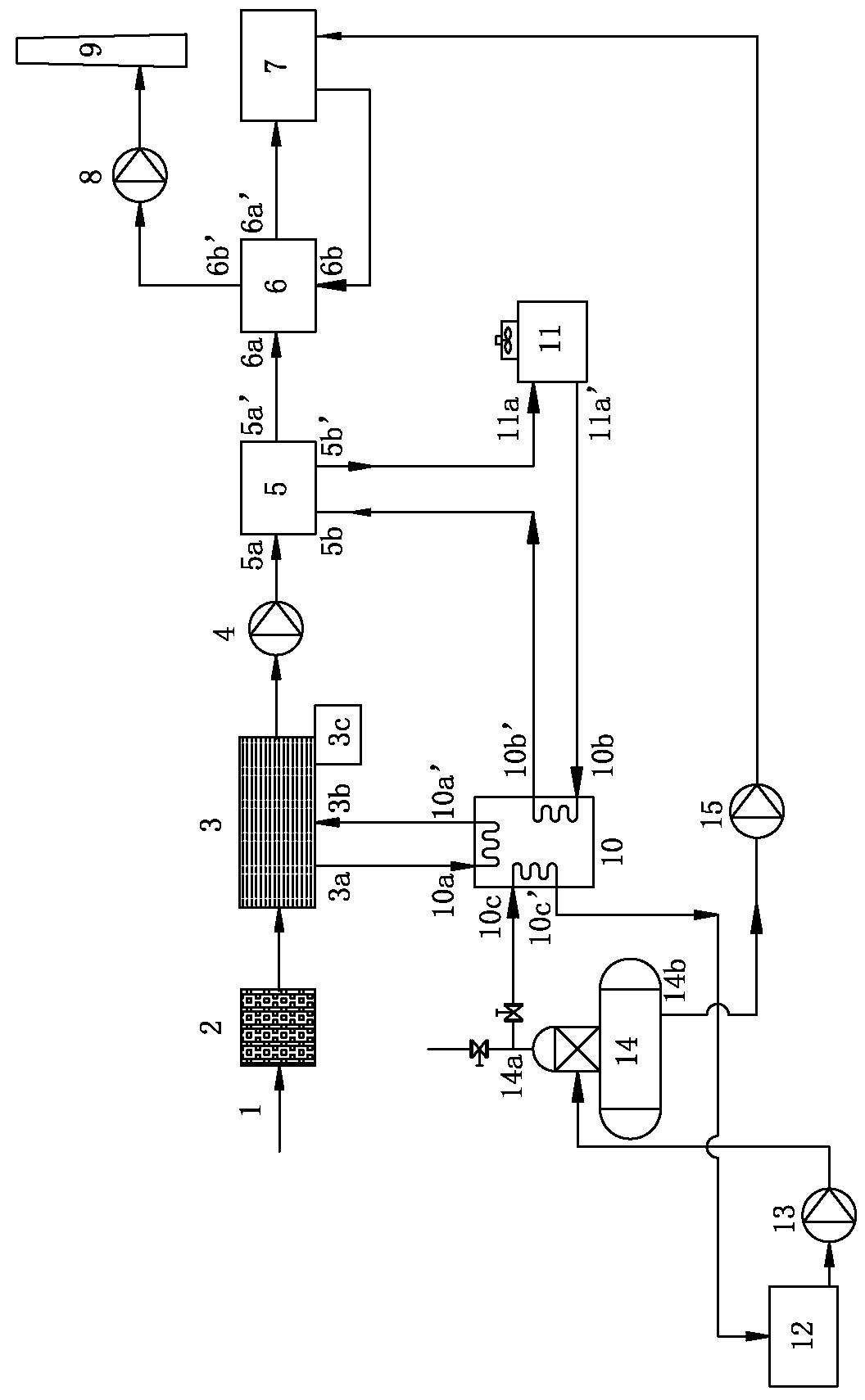

[0011] Such as figure 1 As shown, the air blast dehumidification heating steam boiler system with deaerator of the present invention comprises an air filter 2, a surface cooler and a demister 3, a blower 4, an air heater 5, an air preheater 6, a boiler 7, a Fan 8, lithium bromide refrigerator 10, cooling tower 11, desalted water tank 12, make-up water pump 13, deaerator 14, feed water pump 15.

[0012] The natural air 1 is filtered by the air filter 2 and enters the inlet of the surface cooler and the demister 3, the outlet of the surface cooler and the demister 3 is connected to the suction port of the blower 4, and the outlet of the blower 4 is connected to the air heater The dry air inlet 5a of the air heater 5, the dry air outlet 5a' of the air heater are connected to the cold air inlet 6a of the air preheater 6, and the hot air outlet 6a' of the air preheater 6 is connected to the air inlet of the boiler 7.

[0013] The supplementary water pump 13 sends the desalted wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com