Anode active material for lithium secondary batteries, anode electrode for lithium secondary batteries, in-vehicle lithium secondary battery using said anode active material and anode electrode, and method for manufacturing an anode active material for lithium secondary batteries

一种负极活性物质、锂二次电池的技术,应用在二次电池、电池电极、电池等方向,能够解决输出特性不能充分地实用化等问题,达到性能平衡性优良、提高输出特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Using pitch purified from coal-based heavy oil by removing quinoline-insoluble components, heat treatment at 500°C for 24 hours by the delayed coking method to produce lump coke (green coke), and use a jet mill Fine pulverization and sizing were carried out to obtain green coke powder with an average particle diameter of 9.9 μm.

[0054] Through a rotary kiln, the lump-shaped raw coke obtained as above is heat-treated at a temperature from 700° C. near the inlet to 1500° C. (the highest reaching temperature) near the outlet for more than 1 hour to obtain lump-shaped roasted coke. Fine pulverization and sizing were carried out with a jet mill to obtain calcined coke powder with an average particle diameter of 9.5 μm.

[0055] With respect to 70 parts by weight of green coke powder and 30 parts by weight of roasted coke powder (100 parts by weight of coke material) obtained as described above, phosphoric acid ester (14 mass % active phosphorus solid resin: manufactured by...

Embodiment 2~4

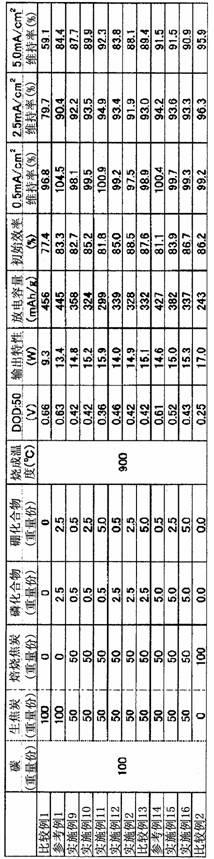

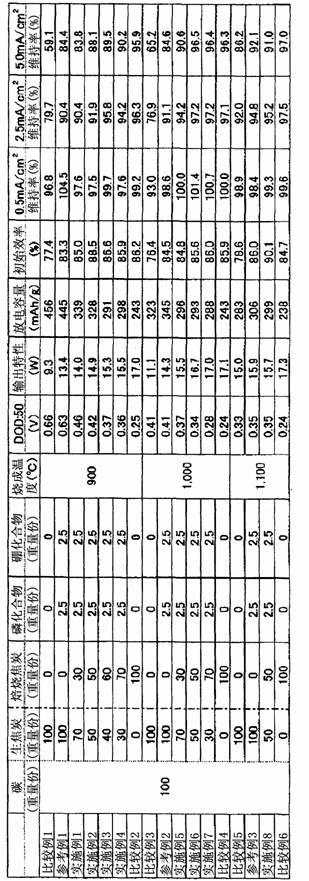

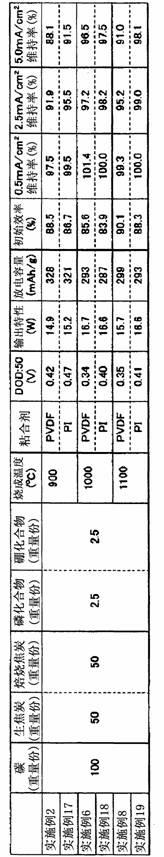

[0060] In Example 1, the mixing ratio of green coke powder and roasted coke powder was changed from 70:30 by weight to 50:50 (Example 2), 40:60 (Example 3) and 30:70 (Example 3) respectively. Example 4), except that, the same operation as in Example 1 was performed to obtain a negative electrode active material for a lithium secondary battery. The results are shown in Table 1.

reference example 1

[0062] Except having used the coke material of 100 weight part of green coke powder (no roasted coke powder was mixed), the same operation as Example 1 was performed, and the negative electrode active material for lithium secondary batteries was obtained. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com