Nanometer artificial bone framework with transverse gradient hole structure and preparation method thereof

A gradient hole, artificial bone technology, applied in bone implants, medical science, prosthesis, etc., can solve the problems of nano-artificial bone scaffolds that have not been reported in the literature, and achieve good biomechanical properties, easy access, and high cell proliferation rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

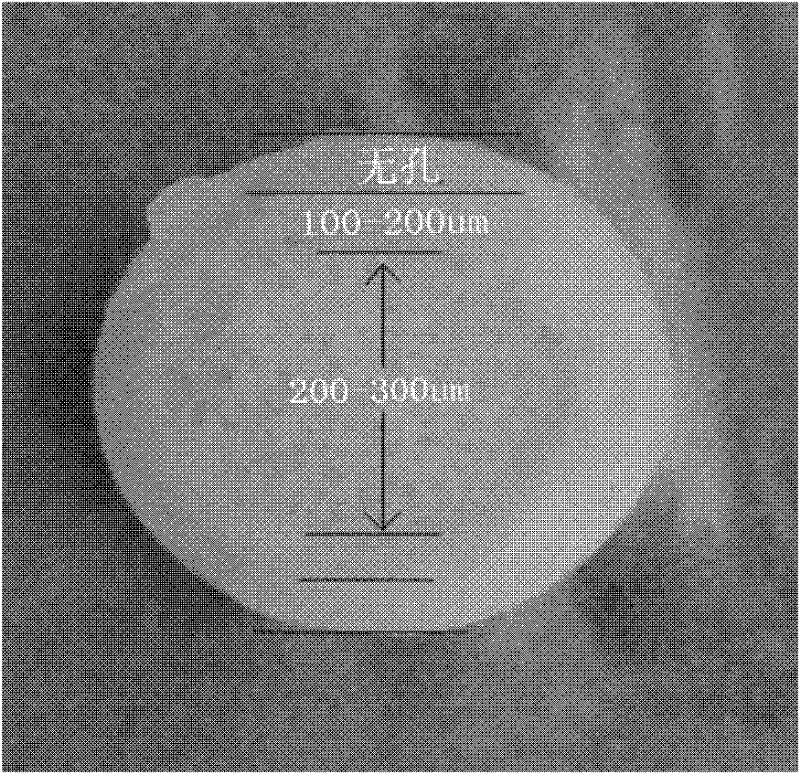

[0037] Embodiment 1: Prepare the nano-hydroxyapatite / polycaprolactone artificial bone scaffold of the transverse gradient pore structure of 10% HA

[0038] Use a stainless steel sieve to sieve the salt into 100um-200um and 200um-300um particles for later use. Heat 3 g of HA / PCL composite material with HA content of 10% to 100°C to melt, add 30mL solvent dimethylacetamide to it, raise the temperature to 120-130°C, and stir slowly until the sample becomes a solution-like substance. Add 12 g of table salt with a particle size of 200-300 μm therein, and keep stirring so that the table salt is evenly distributed in the solution, and at the same time, let the solvent evaporate gradually. After the solvent evaporates completely, take the sample out, put it into a polytetrafluoroethylene tube with an inner diameter of 6mm and a wall thickness of 1mm, and then squeeze it from the upper and lower ends to the middle with a polytetrafluoroethylene rod with a diameter of 6mm, so that The ...

Embodiment 2

[0039] Example 2: Preparation of nano-hydroxyapatite / polycaprolactone artificial bone scaffold with 20% HA transverse gradient pore structure.

[0040] Use a stainless steel sieve to sieve the salt into 100um-200um and 200um-300um particles for later use. Heat 3.5g of HA / PCL composite material with HA content of 20% to 100°C to melt, add 30mL solvent dimethylacetamide to it, raise the temperature to 120-130°C, and stir slowly until the sample becomes a solution-like substance . 12.5 g of table salt with a particle size of 200-300 μm was added thereto, stirring continuously so that the table salt was evenly distributed in the solution, and at the same time, the solvent was gradually evaporated. After the solvent evaporates completely, take the sample out, put it into a polytetrafluoroethylene tube with an inner diameter of 6mm and a wall thickness of 1mm, and then squeeze it from the upper and lower ends to the middle with a polytetrafluoroethylene rod with a diameter of 6mm, ...

Embodiment 3

[0041] Example 3: Preparation of nano-hydroxyapatite / polycaprolactone artificial bone scaffold with 30% HA transverse gradient pore structure.

[0042] Use a stainless steel sieve to sieve the salt into 100um-200um and 200um-300um particles for later use. Heat 3g of HA / PCL composite material with HA content of 30% to 100°C to melt, add 30mL solvent dimethylacetamide to it, raise the temperature to 120-130°C, and stir slowly until the sample becomes a solution-like substance. 13.7 g of table salt with a particle size of 200-300 μm was added thereto, stirring continuously so that the table salt was evenly distributed in the solution, and at the same time, the solvent was gradually evaporated. After the solvent evaporates completely, take the sample out, put it into a polytetrafluoroethylene tube with an inner diameter of 6mm and a wall thickness of 1mm, and then squeeze it from the upper and lower ends to the middle with a polytetrafluoroethylene rod with a diameter of 6mm, so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com