Graphene/lysine nano composite material and preparation method thereof

A nanocomposite material and graphene technology, which is applied in the field of graphene/lysine nanocomposite preparation, can solve the problems such as the difficulty of uniform dispersion and agglomeration of graphene, and achieve excellent biocompatibility, water solubility, and production efficiency. The effect of high and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] ①Preparation of graphite oxide: Slowly add 1g of 200 mesh natural graphite powder into a 500ml beaker containing 23ml of concentrated sulfuric acid under stirring, keep the temperature at 0°C, then slowly add 0.5g of sodium nitrate and 3g of potassium permanganate The mixture was stirred and reacted at 0°C for 2 hours, and then kept in a constant temperature water bath at 35°C for 30 minutes under stirring, slowly adding 46ml of water to raise the temperature to 98°C, and maintained at this temperature for 15 minutes; dilute to 140ml with warm water, pour Inject a certain amount of H 2 o 2 , at this time the color of the solution turns bright yellow, filter it while it is hot, and wash the filter cake fully with 5% HCl until there is no SO in the filtrate 4 2- (with BaCl 2 solution detection), anhydrous CaCl at 50°C 2 In the presence of vacuum drying for 24h, graphite oxide powder was obtained.

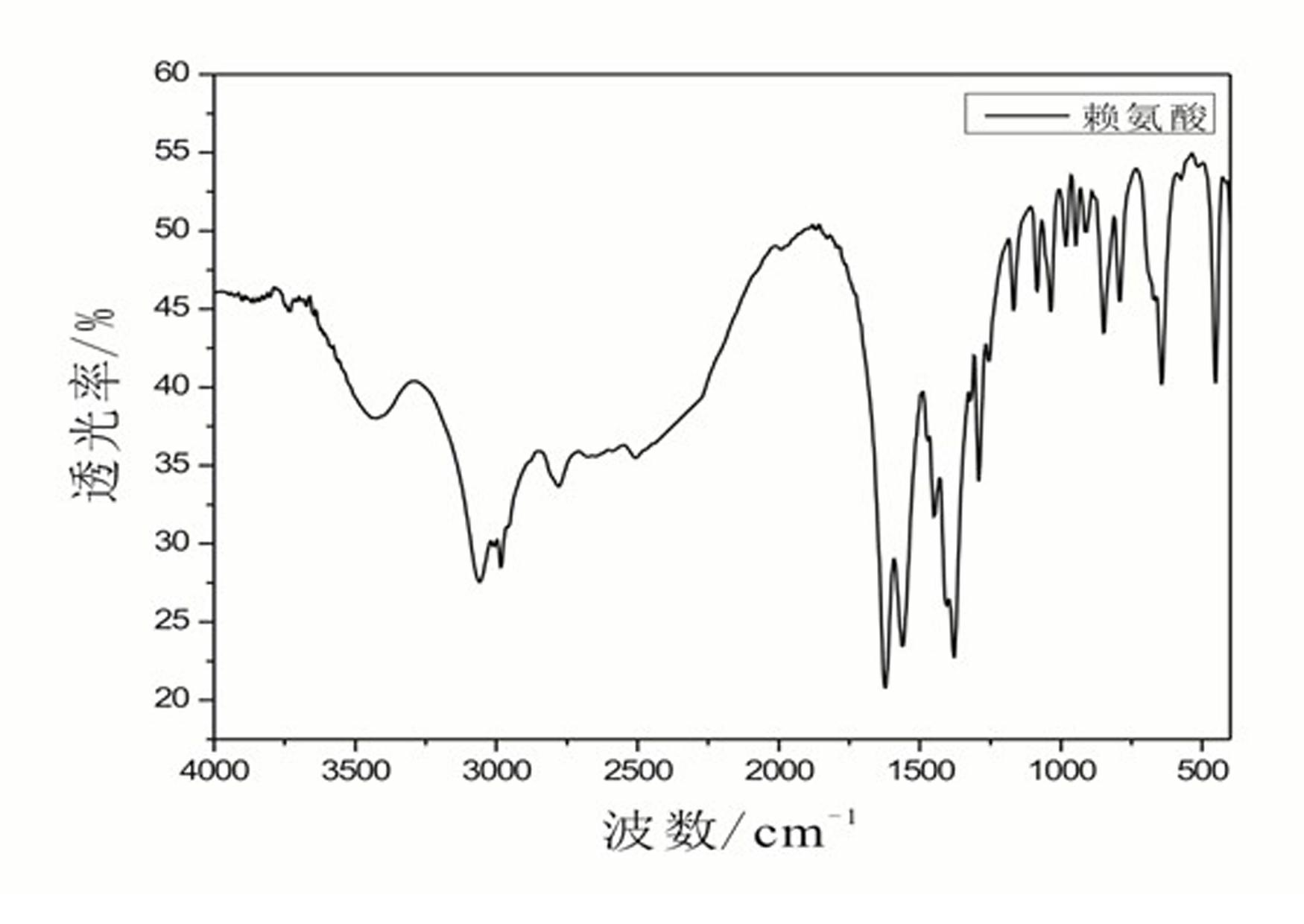

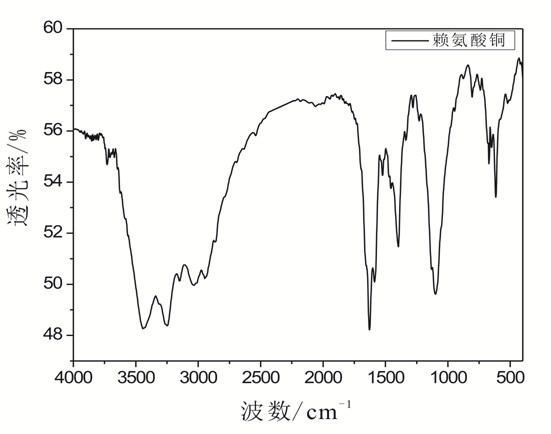

[0034] ② Preparation of copper lysine: Add 1.8g lysine into a round b...

Embodiment 2

[0037] 1. the preparation of graphite oxide: with embodiment 1

[0038] 2. the preparation of copper lysine: with embodiment 1

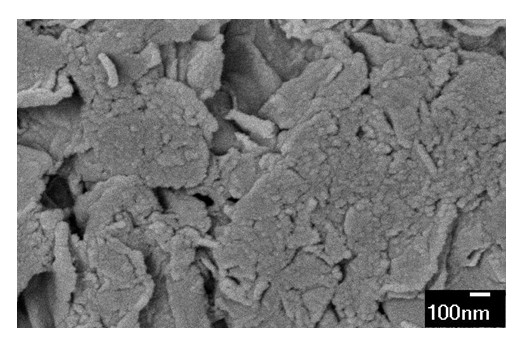

[0039] ③Preparation of graphene / copper lysine nanocomposites: Disperse 0.1 g of graphite oxide in a round-bottomed flask filled with 150 mL of secondary water and sonicate for 1.5 h to obtain a uniformly dispersed graphite oxide suspension. After adding 0.2 g of copper lysine and stirring for 15 min, the pH was adjusted to 9-10 with concentrated NaOH solution, and the reaction was stirred and refluxed at 70° C. for 22 h. Add 0.8g NaBH 4 As a reducing agent, stir and reflux at 70°C for 1.5h, filter the product, wash repeatedly with distilled water, and dry to obtain a nanocomposite of Gs / Lys-Cu-Lys self-assembled layer by layer; Gs / Lys-Cu-Lys Disperse in 150mL of secondary water, add 0.6g disodium ethylenediaminetetraacetate at room temperature, and react for 10 hours to remove copper ions; produce filtrate, wash repeatedly, and dry to obtain Gs / Lys...

Embodiment 3

[0041] 1. the preparation of graphite oxide: with embodiment 1

[0042] 2. the preparation of copper lysine: with embodiment 1

[0043] ③Preparation of graphene / copper lysine nanocomposites: Disperse 0.1 g of graphite oxide in a round-bottomed flask filled with 150 mL of secondary water and sonicate for 1.5 h to obtain a uniformly dispersed graphite oxide suspension. After adding 0.4 g of copper lysine and stirring for 15 min, the pH was adjusted to 9-10 with concentrated NaOH solution, and the reaction was stirred and refluxed at 90° C. for 26 h. Add 1.2g NaBH 4 As a reducing agent, stir and reflux at 90°C for 2.5 hours, filter the product, wash repeatedly with distilled water, and dry to obtain a nanocomposite of Gs / Lys-Cu-Lys self-assembled layer by layer; Gs / Lys-Cu-Lys Disperse in 150mL secondary water, add 1.2g disodium edetate at room temperature, and react for 14 hours to remove copper ions; produce filtrate, after repeated washing, dry to obtain Gs / Lys nanocomposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com