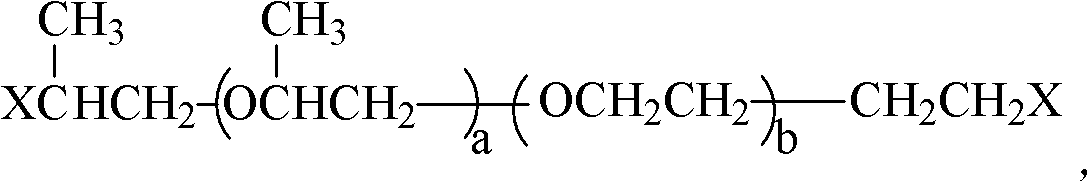

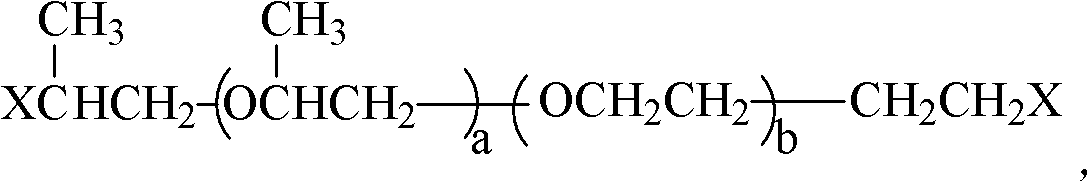

Water-oil dual-purpose dispersion agent as well as preparation method and application thereof

A dispersant, water-oil technology, applied in the direction of pigment slurry, etc., can solve the problems of limited system compatibility, large economic burden, inconvenient use of customers, etc., achieve excellent color development, good dispersion and stability, and save energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

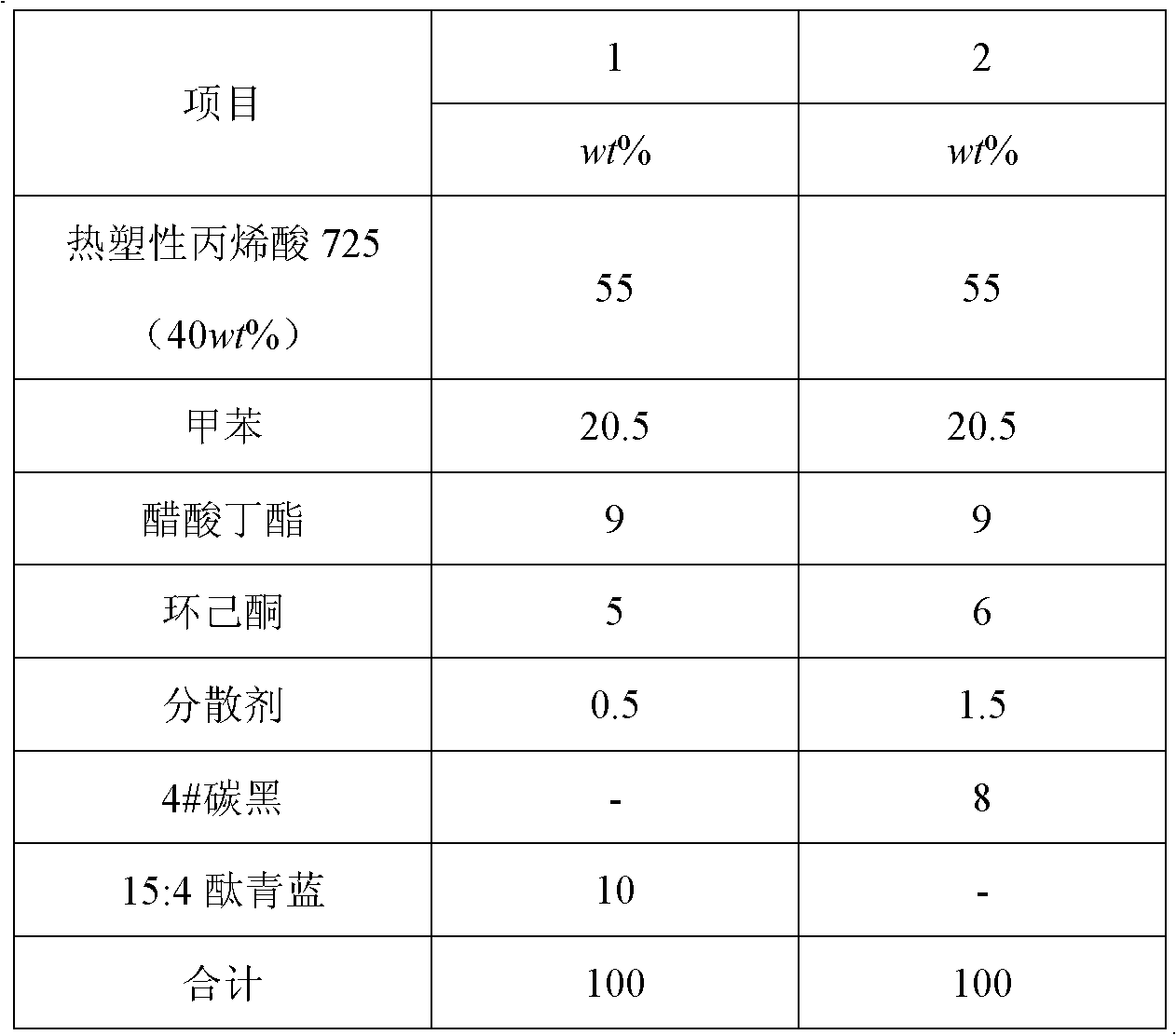

Examples

Embodiment 1

[0044] 1) Into a 100mL four-neck flask, equipped with a thermometer, N 2 , heating and stirring device, add 42 grams of JEFFAMINE M-2070 (polyether monoamine, Hustmans company, average relative molecular weight 2000, EO / PO=31 / 10) and 4.82 grams of ε-caprolactone, be warming up to 160 ℃, dehydration 5 hours, intermediate A was obtained 1 ;

[0045] 2) To 500mL, equipped with thermometer, N 2 , a four-necked flask with a heating and stirring device, add 70 grams of intermediate A 1 15 gram Desmodur N3400 (HDI, NCO%=21.8%, Bayer company), be warming up to 80 ℃, add 0.005 gram T-12 (American gas company), react for 3 hours until NCO% reacts about 92% to obtain target intermediate B 1 .

[0046] 3) Add 3.5 grams of 3-aminopropanol to Intermediate B 1 In the process, raise the temperature to 100°C and react for 5 hours until the amine value is less than 50 mgKOH / g, then cool down to room temperature to obtain the product.

Embodiment 2

[0048] 1) Into a 100mL four-neck flask, equipped with a thermometer, N 2 , heating and stirring device, add 42 grams of JEFFAMIN ED-600 (polyether diamine, average relative molecular weight 600, EO / PO molar ratio=9 / 3.6)) and 4.82 grams of ε-caprolactone, heat up to 160 ° C, dehydrate 6 hours, intermediate A was obtained 2 .

[0049] 2) To 500mL, equipped with thermometer, N 2 , a four-necked flask with a heating and stirring device, add 75 grams of intermediate A 2 , 18 gram Bahydur N3100 (HDI, NCO%=17.4%, Bayer company), be warming up to 80 ℃, add 0.008 gram T-12 (American gas company), react 3 hours to NCO% and react about 90%, obtain the target intermediate Body B 2 .

[0050]3) Add 3 grams of aniline to intermediate B 2 In the process, raise the temperature to 100°C and react for 4 hours until the amine value is less than 50 mgKOH / g, then cool down to room temperature to obtain the product.

Embodiment 3

[0052] 1) Into a 100mL four-neck flask, equipped with a thermometer, N 2 , heating and stirring device, add 42 grams of polyether polyol (polymer polyol EO / PO copolymer, average relative molecular weight 2000, EO / PO=2 / 1) and 2.41 grams of ε-caprolactone, and heat up to 180 ° C , dehydrated for 6 hours to obtain intermediate A 3 .

[0053] 2) 500mL four-neck flask, equipped with a thermometer, N 2 , heating and stirring device, add 82 grams of intermediate A 3 , 18 grams of 2,4,4-trimethyl-1,6-hexamethylene diisocyanate (TMDI, NCO%=39.7%, Bayer Company), warming up to 80°C, adding 0.005 gram of T-12 (American Gas Company), React for several hours until about 90% of the NCO% is reacted to obtain the target intermediate B 3 .

[0054] 3) Add 3.6 grams of p-aminobenzoic acid to intermediate B 3 In the process, raise the temperature to 100°C and react for 2 hours until the amine value is less than 60mgKOH / g, then cool down to room temperature to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com