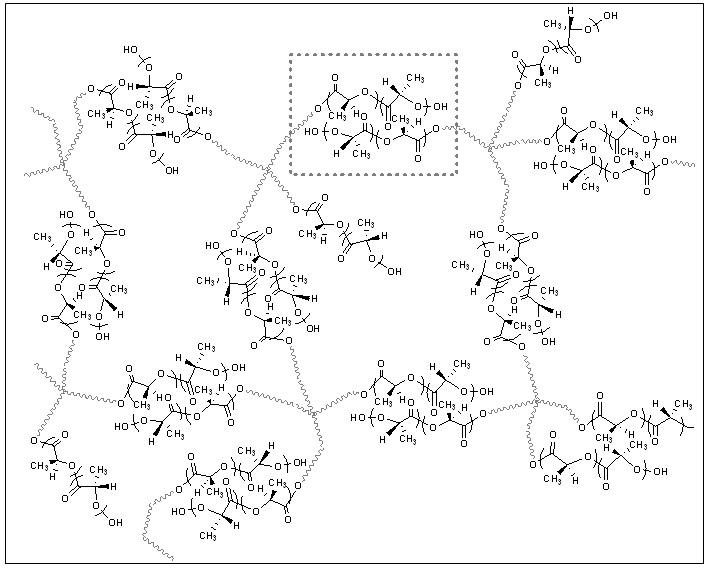

Polylactic-acid-based isotactic compound crosslinking copolymer and preparation method thereof

A technology of polylactic acid copolymer and cross-linked copolymer is applied in the field of polylactic acid-based stereocomposite cross-linked copolymer and its preparation, which can solve the problems of destroying the good degradability, toughness and thermal properties of polylactic acid, and improve the toughness. , the effect of expanding application fields and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

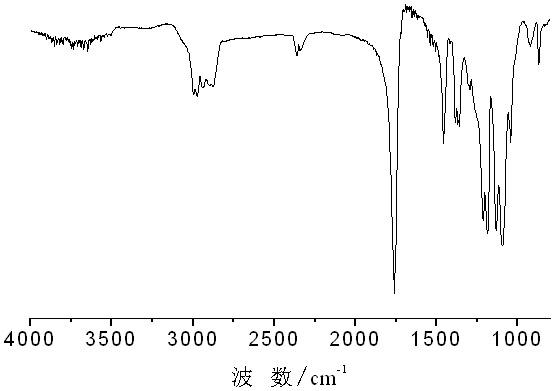

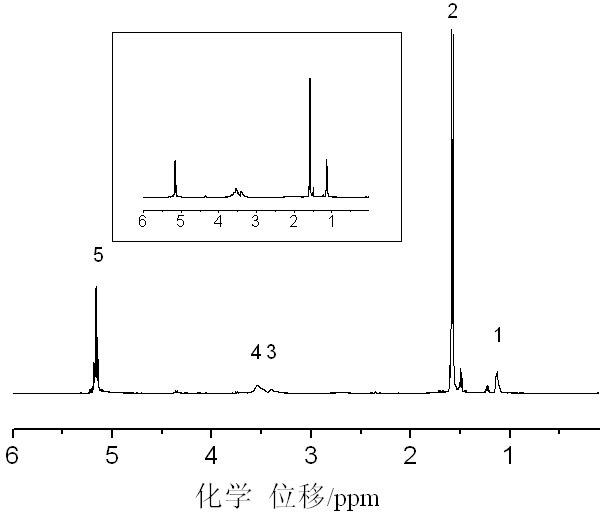

Embodiment 1

[0050] (1) Add 5g of hyperbranched polyether, 12.5g of L-lactide, and 0.05g of zinc lactate into the polymerization tube, wherein the hyperbranched polyether uses trihydroxypropane as the initiator to initiate propylene oxide Prepared, the number average molecular weight is 5000; the optical purity of L-lactide is 96%ee. Filling with argon to catch up with oxygen, vacuuming, repeated three times, control the vacuum degree in the polymerization tube to be 10KPa, the temperature is 130°C, and react for 72 hours. The obtained product was purified, and its number average molecular weight was determined to be 16500.

[0051] (2) Weigh 16.5g of the prepolymer obtained in step (1) and 0.5g of stannous octoate, and dissolve them in 100ml of anhydrous toluene. Nitrogen was blown, and the reaction temperature was controlled at 50° C. for 4 hours. After the reaction, unreacted stannous octoate was removed by suction filtration, and vacuum-dried to obtain a terminal-modified three-branc...

Embodiment 2

[0062]Step (1) and step (2) are as shown in Example 1. Add the block copolymer obtained in step (2) and 25 g of D-lactide with an optical purity of 97% ee into the polymerization tube, and fill it with argon Catch oxygen, vacuum, repeat three times, control the vacuum in the polymerization tube to 5KPa, the temperature is 130°C, and react for 72 hours to obtain three-branched propylene oxide polyether-L-polylactic acid-D-polylactic acid stereotactic Composite cross-linked copolymer. The obtained product was purified, and its number average molecular weight was determined to be 35700. According to the method listed in Example 1, the mass ratio of tribranched propylene oxide polyether, L-polylactic acid, and D-polylactic acid in the block copolymer is measured to be 1:2:4; melting point is 195°C; elongation at break The rate is 198%; the deformation recovery rate is 97%, and the deformation fixation rate is 99%.

Embodiment 3

[0064] Step (1) and step (2) are as shown in Example 1. Add the block copolymer obtained in step (2) and 45 g of D-lactide with an optical purity of 97% ee into the polymerization tube, and fill it with argon Catch oxygen, vacuum, repeat three times, control the vacuum in the polymerization tube to 1KPa, the temperature is 130°C, and react for 72 hours to obtain three-branched propylene oxide polyether-L-polylactic acid-D-polylactic acid stereotactic Composite cross-linked copolymer. The obtained product was purified, and its number average molecular weight was determined to be 51,100. According to the method listed in Example 1, the mass ratio of tribranched propylene oxide polyether, L-polylactic acid, and D-polylactic acid in the block copolymer is measured to be 1:2:7; melting point is 192°C; elongation at break The rate is 112%; the deformation recovery rate is 95%, and the deformation fixation rate is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com