Complex microbial agent for low-temperature methane fermentation and preparation method thereof

A compound microbial agent and low-temperature fermentation technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of biogas production in biogas digesters in winter when decomposing straws, and no low-temperature fermentation of biogas has yet been seen. No need for a variety of products, troublesome use methods, etc., to achieve the effect of accelerated start-up, simple use methods, and strong digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Screening, domestication, breeding and classification of strains

[0039] Under the condition of 10℃, the dominant microorganisms in several differently treated sheep manure biogas reactors were separated, screened, cultured, identified and verified by back-connection experiments, and their effects were compared and analyzed to determine the types of fermentation bacteria. Simultaneously. Using molecular biology methods, the predominant flora of bacteria and fungi in the biogas fermentation tank was separated and identified, samples were collected and DNA extracted from the well-fermented sheep manure biogas reactor, and the 16S rDNA and 18S rDNA of the microbial population were analyzed. Identification and comparison and identification of microbial diversity to determine the type of flora.

[0040] Finally, two strains of R1 and R4 with obvious effects were determined.

[0041] Through the cultivation, separation and screening of microbial strains from the sheep ...

Embodiment 2

[0048] Example 2: Preparation of composite microbial agent for low-temperature fermentation of biogas

[0049] The present invention provides the fermentation broths of Acetobacter, Pseudomonas sp. CGMCC No. 4764 and Pantoea agglomerans CGMCC No. 4765 respectively according to slant culture and activation , Shake flask culture, seed tank liquid fermentation culture, fermentation tank liquid fermentation production, the production conditions are as follows:

[0050] Pseudomonas sp. CGMCC No. 4764 was cultured in LB liquid medium for 24 hours to prepare the strain, 200 ml of the strain was inoculated into 10 liters of PR medium; the fermentation temperature was 28 ℃, and NH 4 OH 28% solution adjusts the pH to 6-8 constantly, preferably 6.8; the stirring rate is 400rpm, the aeration rate is set to 0.4 (V / V); when the biomass concentration reaches 10g / L-40g / L, the fermentation is stopped .

[0051] Pantoea agglomerans (Pantoea agglomerans) CGMCC No. 4765 was cultured in R4F liquid mediu...

Embodiment 3

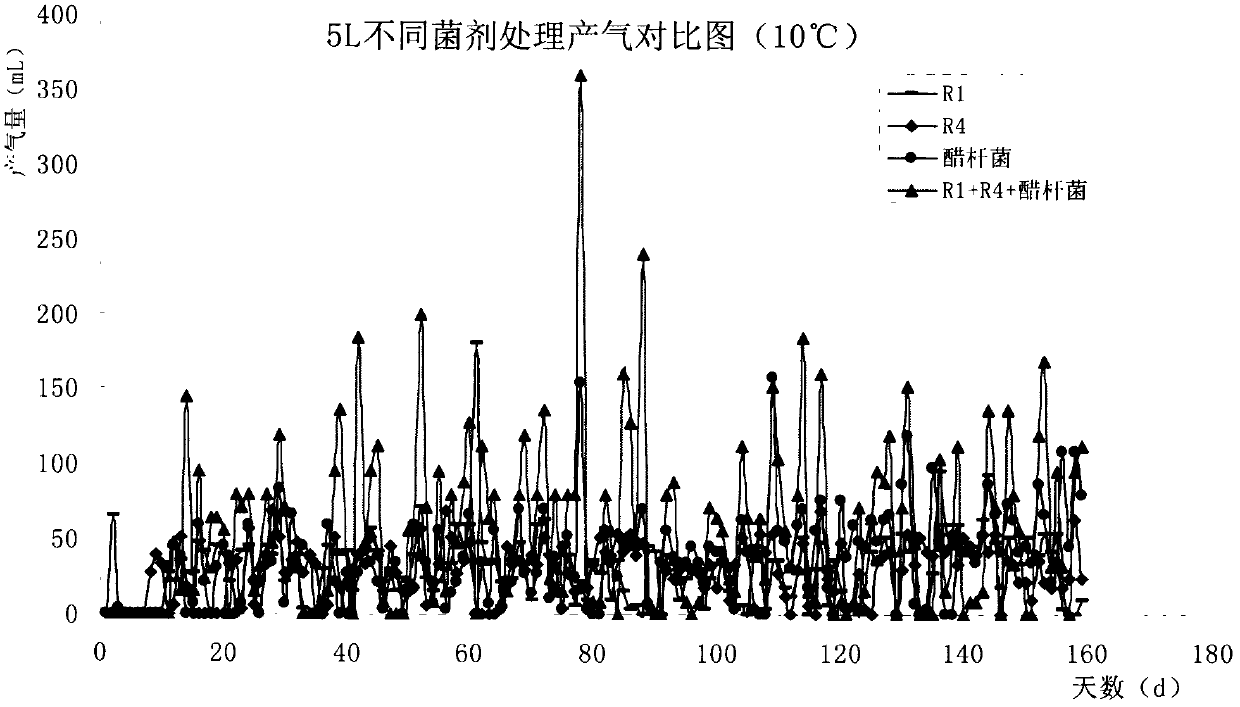

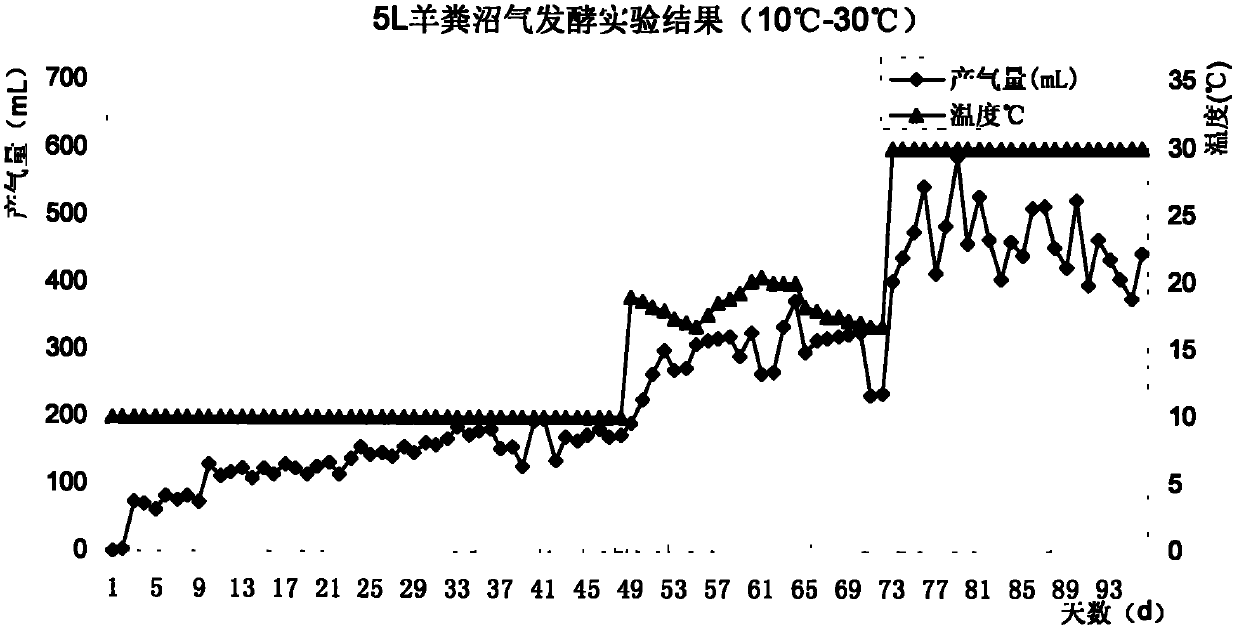

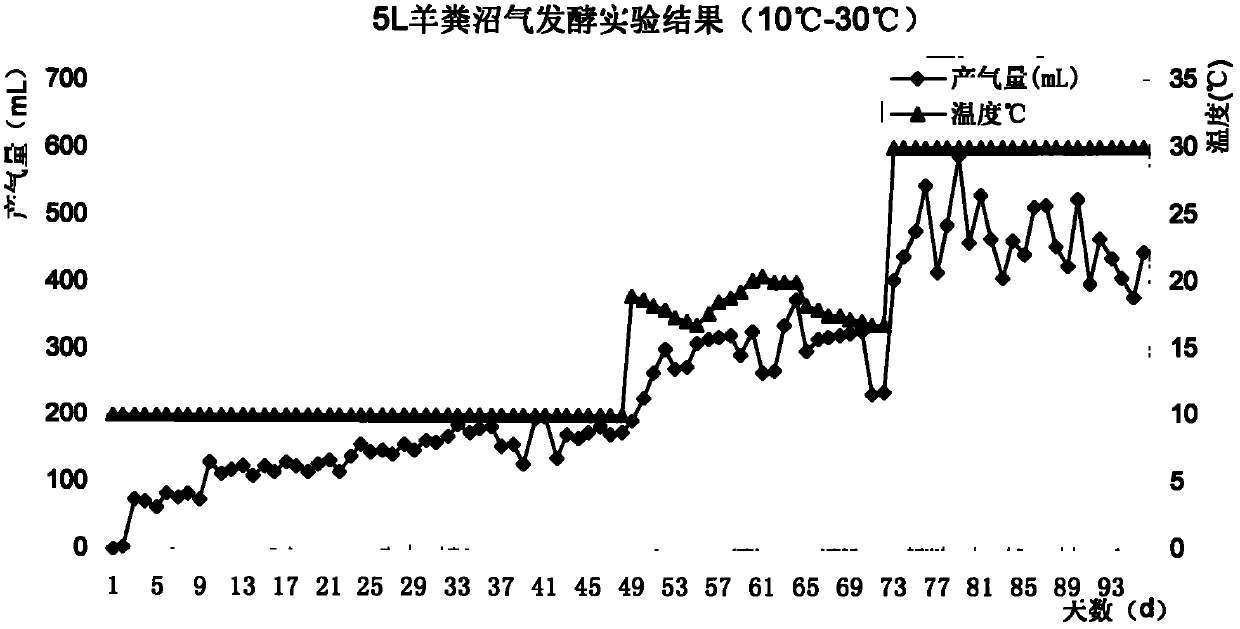

[0059] Example 3: Experimental study on biogas fermentation at 10°C, 15°C-18°C, and 30°C to produce gas

[0060] A 5L tank of sheep manure biogas fermentation bacteria inoculation test (adding 5-10 grams of bacteria) at 10℃, 15℃-18℃ (room temperature) and 30℃ were carried out, and the gas production conditions and gas production rate were tested. . The result is: as long as the temperature of the material liquid in the biogas fermentation device is maintained at more than 10°C, the biogas digester with cattle and sheep dung as the main raw material will increase by more than 30% compared with the non-infected biogas digester. figure 1 , 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com